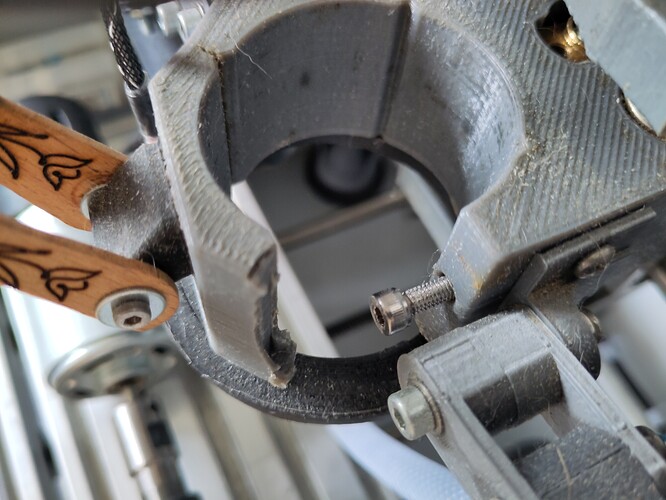

I went to use my 1610 CNC (built from an AliExpress kit, plus careful upgrading) and discovered thie 3D printed Z slider/spindle clamp has failed rather badly:

The machine came with the X caridge (which includes the Z axis+slider) assembled, basically two big and hefty 3D printed pieces. The Z slider has a clamp ring for the spindle, which is what has failed here.

The machine was sold as a ‘dual’ CNC+Laser, with a 755 spindle and a 5W laser module that can be swapped in the clamp. The clamp design has been ‘modified’ with a square cut out intersecting the spindle ring that grips the laser module. The clamp has failed at two of these cutouts, and the material there is definately quite brittle (5 year old PLA). It failed in use, I have not had the laser module fitted for the last year+.

I need to use this for a PCB cut asap; solution is 3-fold:

- Remove the Z slider.

- Remove the laser module, wiring, fans, switches and it’s dedicated power rail. I have a much better laser machine and the CNC is not properly ventilated anyway.

- Cut the remains of the Z slider along the X axis, cut a wooden plate that fits that and bodge(*) the two together. Then I construct a better spindle mount on the wood, this eases my spindle upgrade path for the future too.

A picture taken when I was building the machine, the carriage is lying on it’s back with the spindle mounted.

(*) Bodge: A UK phrase meaning to fix with glue/tape/nails and whatever is at hand, using hammers whenever possible.