Hi guys,

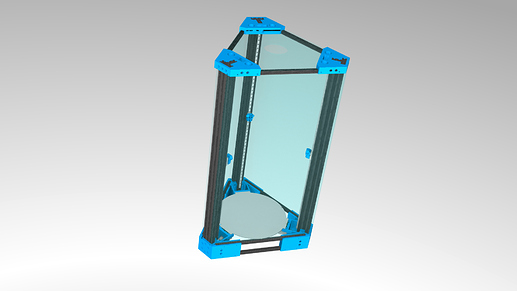

Just wanted to share my ongoing big delta build progress, because I believe the design work is nearly finished. I’m currently printing the parts to assemble V3 overall.

The design is open sourced and done in FreeCAD 0.19pre: https://github.com/goeland86/MonsterKossel

I’ve had the v2 iteration printing for a long time now, with varying degrees of success depending on what specific upgrade I was trying out. Specifically what changes drastically in V3 is that the whole drawing is done with FreeCAD where V2 was done in Blender.

For this big delta, there were a few key concepts I wanted to stick to as much as possible:

- Compatibility with Kossel parts where possible

- Ease of maintenance for any of the components that wear out

- High quality prints at high speed

- Ability to handle exotic filaments

Therefore the design incorporates the following features:

- screw-mounted motor / bed support brackets

- under-bed piezo sensors (Andromeda mounts from PrecisionPiezo)

- Remote-Direct-Drive extruder - meaning this is not a Bowden setup, flexibles are easily handled

- Telescoping torque shaft to bring the stepper motion to the effector without adding weight

- Ability to fully enclose (and easily re-open) the printer with acrylic panels, shapes for laser-cutting provided

- use of MGN9 rails for linear motion

- massively rigid frame that will not budge during printing

The remote drive extruder isn’t my own design, and hasn’t been officially released by the designer, so I’m holding off on that - but using a Kossel effector with a Zesty Nimble or Flex3drive is also possible. The carriages use the standard 40mm spacing between the arms - what the Kossel Mini and Kossel XL were designed around.

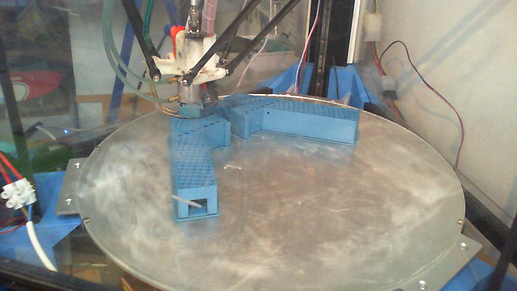

Pictures will be forthcoming of the printer as the V3 is being assembled. Right now I only have webcam shots of the bottom frame part being printed:

Wiring is definitely getting an improvement in V3 - so you won’t see any of the cables currently visible on V2. The bed is 350mm in diameter (just a little over 13.5" for you imperial folks). I hope this design appeals to folks who wanted a large delta but weren’t particularly confident in designing their own.

The telescoping shaft is, to the best of my knowledge, a world first in the delta printer space - I’d be happy to have that claim corrected however. I built mine from scratch out of square tubing, as nothing was commercially available to match the specs I needed. See a video of an early iteration of it in action here: https://twitter.com/Goeland86/status/1271207353896054790?s=20