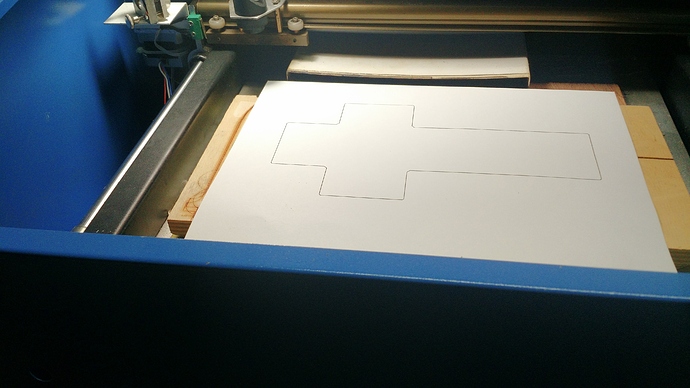

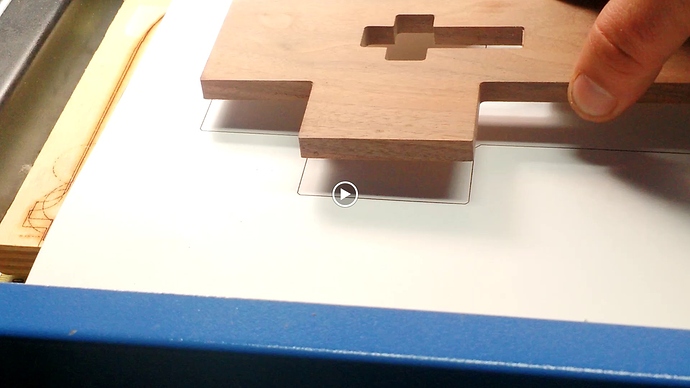

Many apologies for not posting a video yesterday. For alignment of irregular shaped parts for laser engraving I had a bum rush day of finishing several graduation presents… When working with irregular shaped items that require alignment it’s best to have a waste substrate such as card stock to work with… I use card stock because you can mark it with low power without cutting trough. A set of calipers or a steel ruler/scale will be needed to complete this project. I take my measurements of the part and get atleast 3 points of alignment to register to but 4/5 are better. Using those measurements I draw up a rough draft of the part and engrave it in card stock so I can lay the part on it

Are you running with a thick piece of ply below the cardstock as your cutting bed? Or just to raise the engrave height up a bit?

Reminds me of softjaws on CNC mills!