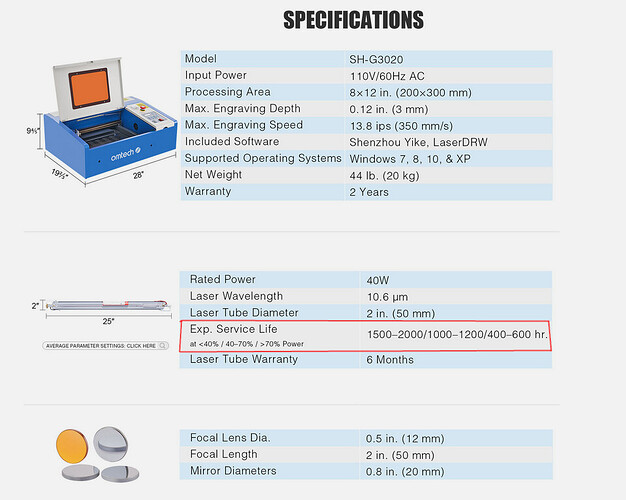

Last night I was happily cutting acrylic and 3mm ply when I needed to do a quick design change, made it available to my K40 and pressed send only to notice that there was no beam and on closer inspection, there was no beam coming from the tube. Furthermore, although my digital voltmeter was still registering tube voltage there was no movement from the ammeter, so having tried powering down and up a few times without success, I concluded the worst – LPS or tube or both gone bad!! So, I did a search on the site and came up with a post “This is my first post on here and I am hoping to get some” from Josh_Hutch in Dec 2017 which looks identical to my problem. In this post it was concluded to be the LPS not the tube. Bearing in mind I only changed out the LPS and tube together to Cloudray in July last year, this is extremely disappointing. Reflecting back, I have done a lot of cutting in that time of maybe 100 to 150, 300x200mm 3.5mm ply and mdf boards but all have been cut inside the laser spec (15mA which is 3.6v in my case and not higher that 20C using my DIY chiller). In July last year, when I had the original problem, we tried the LPS first, and this did not fix the problem so we changed out the tube which did but I kept the new LPS on the machine and held the stock LPS as a spare, but I never knew if this had also failed. I have now changed it for the spare and bingo it works so it is the LPS and I have confirmed this with some cutting today. The only other thing I can add to this sorry saga is the following. Around 2 weeks ago I noted an inability to fully cut the ply and checked all the usual suspects. In the end, I found this to be a cracked lens which was purchased along with new mirrors when I upgraded my full head set to a Cloudray CO2 laser head set in November. I had also noted a quiet buzzing noise which I took to being part of the above problem. When I replaced the lens a few days ago and I was back in business but I noticed the buzz was still there at times so perhaps in hindsight this was the LPS on its way out. The questions I have are as follows:

- I presume you agree that the LPS has gone bad. With such a short life of 6 months, I have asked Cloudray through Amazon for a replacement or a deal but I am not hopeful.

- Looking inside the LPS I can see nothing that shows what part might have failed. I presume there is no obvious repair that can be tried?

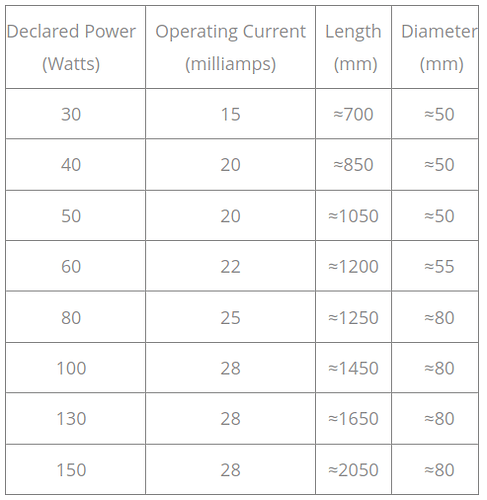

- I bought both LPS and tube through Amazon and I have noted they have a 50W variant versus the 40W part I purchased last time. Would it be better to purchase the uprated version to maybe provide greater reliability?

- Once replaced I will hold my stock LPS in reserve as I now know it works and it will help in any future diagnosis.

- Although I appreciate both LPS and tube are consumables, is there anything more I can do to help prolong life of both LPS and tube bearing in mind that I do a lot of cutting.

- Any ideas why my lens might have cracked?