Look what Mark put together.

Cool little scanner.

Originally shared by Mark Miller

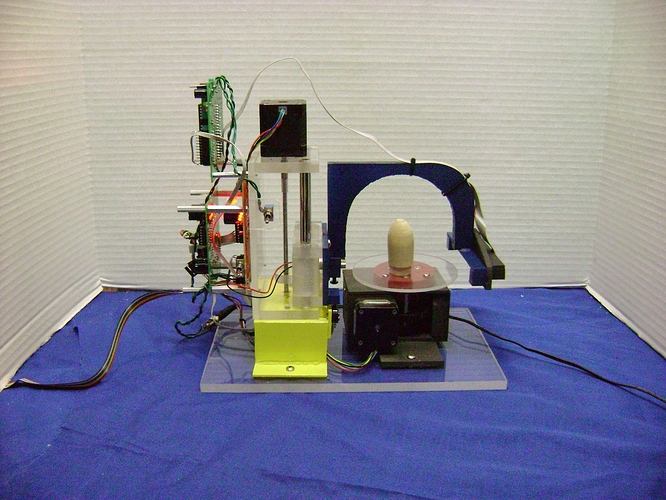

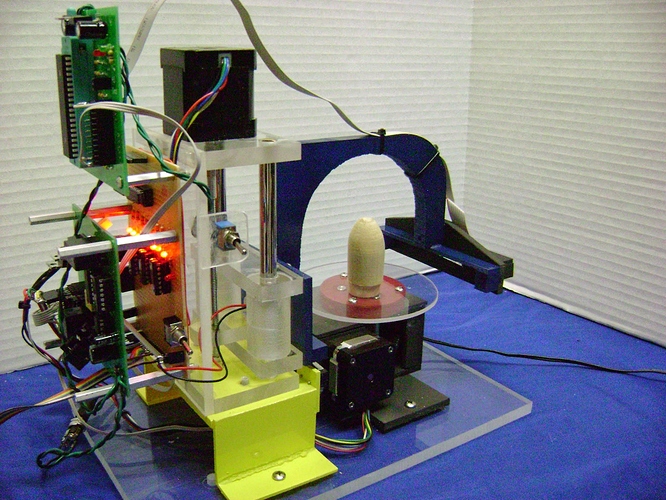

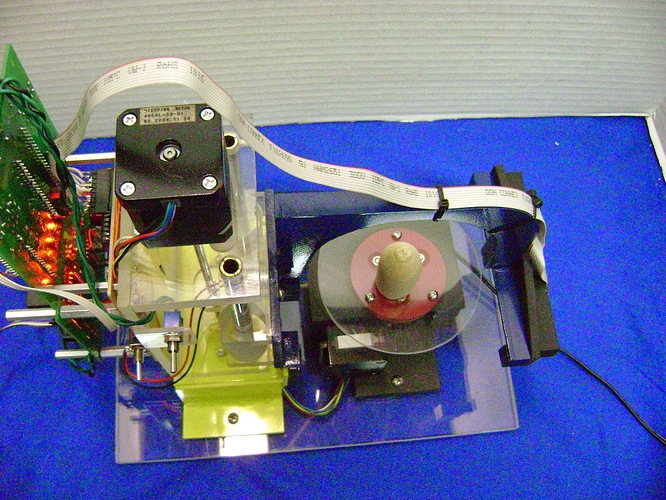

Home made 3D mechanical scanner

This is my second homebuilt scanner, and is much faster and easier to use than my first. I wanted this to use in conjunction with my home made CNC machines(see my profile page for more info on them), this one specifically for the mini lathe to scan a profile of a part directly into the machine for part production.

This is made from bare minimum scratch. The sensor array the line laser shoots into, is made up of small rectangular individual sensors 1/16 inch wide each arranged in a row so each turn of the leadscrew “snaps” a picture from the sensor array and sends it into memory. Very challenging to get them all perfectly lined up, but they are so very inexpensive(less than 5$) that it made it worthwhile. The resolution is good enough for what I am doing.The line laser is from ebay.

A pic controller runs the stepper and logic. Output is 8 bits wide.

As you can see in the video, it’s pretty fast and simple to use.

The rotary table will be used later for full aspect (non-concentric)scanning. Right now I am happy to get some lather profiles done really fast and simple.

The machine is made from acrylic bits and pieces.

I am going to clean up this design a bit, and get it into a nice cabinet as it is something I will be using often.