I have a problem which I do not know the answer for.

The laser tube only fires above a 25% power setting. The beam is purple no arcing and water supply is good. Temp below 20 deg.

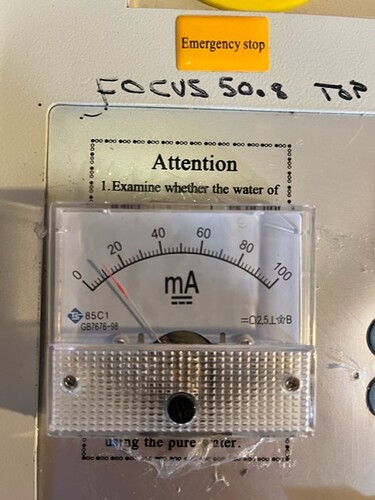

At all power settings the Ma readings are half of what they should be. The laser at 100% reads 10Ma…which is the max reading I get.

I have measured across the psu terminals and get a 24v and 5v readings. (right hand connector.

The green light on the power pack is showing but when the test button is pressed no beam in the tube.

It would seem to me that the tube is not getting sufficient power but I am not sure about this and do not know how to check this.

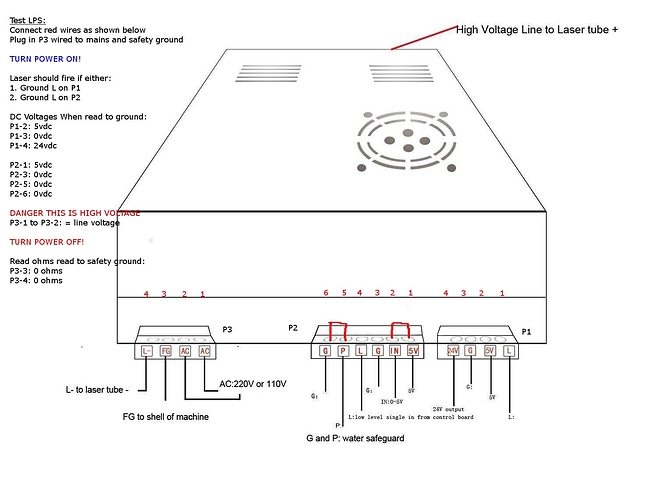

I have the standard psu with green connectors.

Any help or suggestions will be appreciated. Thanks

The machine wouldn’t work at all without the 5V and 24V working. The laser power supply (lps) dc voltage excites the tube, which it sound like it’s doing.

I’d check the TEM mode or resonance of the tube at m1. If it’s not TEM00, then you probably lost the tube…

There isn’t much else if your pwm is working, which is assumed. The lps takes it from there.

![]()

Post pictures of:

- The connector side of your Laser Power Supply (LPS).

- The control plane

In this scenario:

- How are you firing the tube ?

- How are you setting the power?

- What test button are you referring to? On the LPS or on the control panel.

- Relative to ground what does the “IN” pin on the LPS measure?

| donkjr Don Kleinschnitz Jr. Don

November 6 |

- | - |

Good morning.

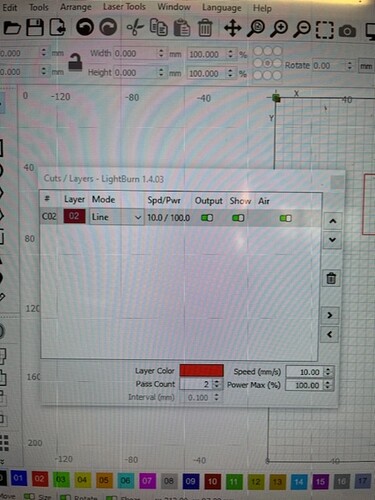

Thanks for your quick response. I have attached the images you asked for as well as two others . One shows the Lightburn setting at 100% and the other showing the Ma reading at 100% power.

PTost pictures of:

- The connector side of your Laser Power Supply (LPS). Image attached

- The control plane. Image attached . It is not used as the laser is controlled through Lightburn. ( FluidNC board)

Alex_Park:

The laser tube only fires above a 25% power setting.

In this scenario:

- How are you firing the tube ? Using the small red test button next to the green light on power supply. (Image attached)

- How are you setting the power? Through Lightburn. FluidNC control board installed. (Image attached)

Alex_Park:

The green light on the power pack is showing but when the test button is pressed no beam in the tube.

- What test button are you referring to? On the LPS or on the control panel. On the LPS

- Relative to ground what does the “IN” pin on the LPS measure? 0.18 V

Hello Don.

I have, after sending the earlier email to you I thought I would try increasing the S-value max to 1000% The power output reading on the Ma gauge now reads correctly and the laser tube is back to full power.

Once again, thank you for taking the trouble to assist

Regards.

Alex

This was the first post…

![]()

Correct. Thanks

I’m glad it’s working again, I wonder why Lightburn has to be at 1000%.

Just FYI; to be at full power the “IN” pin should be close to 5V.

I am not sure which the IN pin is. The 5v and 24v pins read correctly.

I think you mean " S-value max to 1000" instead of a percent. On old 8bit controllers the S-value was 255 but with new 32bit controllers the range is now 1000. What’s odd is how this got changed.

There is a signal on the LPS “IN” that controls the power when pushing the test button on the LSP.

The 0-5 voltage on this pin sets the maximum current the LPS can output.

This is the default with Lightburn, as is stated in the Lightburn grbl setup.

The documentation is a good place to start when it doesn’t work…

Spouse says men can’t read instructions… ![]()

![]()

Yes, sorry should not have shown it as a %. I wish I had known this adjustment at the start. Would have saved hours.

I only found this by trial and error by changing settings in LB configuration.

All’s good that ends well and one more thing to bear in mind in future.

And it’s a good thing you ran across that and tried changing it because otherwise it would have been hours more of your time and others here since we would have been looking at the hardware and signals first.

FWIW, the older micro-processors used on these things were 8 bit procesors where there literally were 8 little segments in how they stored information( 1111 1111 ) which is called a Byte. Because of only having 8 ones/zeroes to store a number it meant there were only 256 different numbers which could be stored. So when a pulse was generated to represent 0%-100% power there were only 256 different values. 50% power was a value of 225. BUT, new boards use 32bits of data to store numbers and that’s huge for an unsigned integer( 4,294,967,295 ) and that’s way more than is what’s needed for varying power so 1000 was decided as good enough. ie 1000 different levels to get 0%-100% power so at 50% power the number 500 would be sent/uses.

When you had S-Value at 256 then 100% power was the number 255( 0 counts as one number ) and 255 is only 1/4 of the way to 1000 so you were only getting 25% of your actual power output.

Hopefully that made sense.

IMHO, you can’t get any material I know down to the 8 bit, 256 range of gray, let alone a 64k range… ![]()

These were done on a fiber. That source has an 8 bit power control (parallel port) source…

This guys work always make me green, they are great, but shows what 8 bits can do… or at least what’s possible…

The simple fact is that @Alex_Park would not have had the issue if he had spent 2 minutes reading the setup for his machine.

If anything they are plug and pray, not what most people expect.

@Alex_Park I’m not scolding you, just a reminder to take a few and check out the installation and use documentation if you have issue… These operate very simple, but the devil is in the details. You find the devils or the details in the documentation.

We’ve all been there and screwed up, just like you… so hang in there…

![]()

It does. Thanks for this. Never thought about checking the settings in LB before looking for a hardware issue!

Point taken. I must say I very seldom read the detail in documentation supplied.

Need to remember the advice in future.![]()