I am using laserweb for my cnc plasmacutter.

That’s not exactly a laser, but for 95% the software has to do the same thing.

Difference is that my plasmacutter has a pretty wide cuttinghole (approximately 2mm).

To get my parts on the exact right measurement i want to use laser cut outside and inside to create the offset.

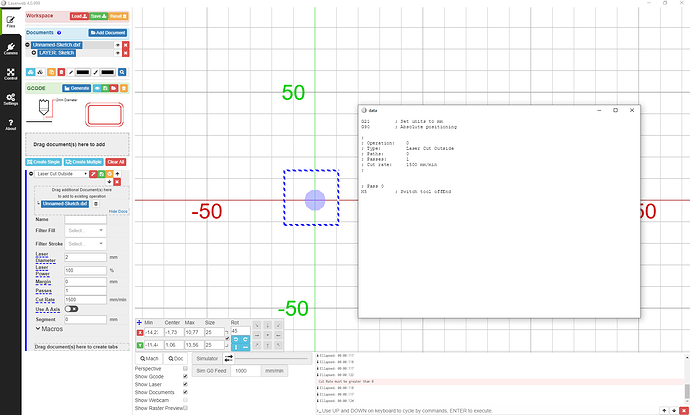

Unfortunaly when i draw a dxf in onshape, and process that in laserweb the file does have a start and end gcode, but no movements coordinates at all.

Any ideas what i am missing?

How does LaserWeb differentiate between cutting and engraving processes(it is laser software)?

Isn’t it by the color of the design lines?

Also, look for a setting of the kerf somewhere in LaserWeb. The kerf is the diameter of the cut and for lasers it’s really small(less than 1 mm). You should be able to change the default kerf size to get your inside and outside dimensions closer.

@Jelle_Stappers : Could you please upload the .DXF file?

There is a clue in the Gcode shown; the number of selected paths is zero. And I’m not seeing a path in the display, just a selection box.

I think the error is in the DXF import, not code generation. A copy of the DXF will let me analyse this further.

@dougl : With LaserWeb the source (dxf or svg) is broken down into paths; which can be selected in the document screen or in the document tree (top left of the UI).

You then drag these paths from the document selector to to the ‘add jobs’ box (the box below the document selection one), and select the job ‘type’ and options there. You can build a list of jobs this way, .

You /can/ filter jobs by path color but it is not the default way of doing things in LW.

The beam diameter setting is, in effect, the kerf setting. You can specify a simple cut (centered on the path) or ‘cut outside /cut inside’ with the beam radius (diameter/2) determining the relevant offset.

Beam diameter also plays a role in fill and raster engraving cuts. And setting it right is important to getting good results. My diode laser has, in theory, a 0.08mm beam. But when engraving I tend to set it to 0.15 and defocus the machine a little (z axis raise) to compensate.

@Jelle_Stappers

PS: Welcome to the forums, I’ve moved your post into the LaserWeb support area since that seems more appropriate.

Nice to hear of someone using LW for novel purposes, I know it is being used for a hobby EDM tool too.

LW is pretty flexible in this regard, so long as it is talking to a compatible controller. It also has ‘CNC’ job types which allow for Z lift between moves, passes at different depths, etc…

I love Plasma Cutters, I used a manual one once at technical college and was gobsmacked at how well it chewed holes out of some quarter inch steel plate. Fun apparatus to use.

Part Studio 1 - Sketch.dxf (50.8 KB)

I draw these with onshape as it’s nice to do simple stuff in the browser, but i already figured out that onshape seems to do a bad job exporting…

Thank you.

I actually have alot of experience with a 100W CO2 laser, but that one runs on a ruida and i prep everything with lightburn for it.

I found laserweb thanks to a friend. And it seems a nice light program, exactly what i need, it just needs to take my offset as the kerf of the plasmacutter is just gigantic if you compare it to a lasercutter.

I wanted this cnc plasma for years, but i found this one on ebay for not too much money (used) and it’s a nice size with 1,30x1,50m.

yep… .dxf is a bit of a nightmare in the first place; a proprietary format with many versions, changed at whim by adobe. But even then, this is a horribe .dxf

It certainly fails to import properly in LaserWeb;

- Internally; it is a series of disconnected and unclosed paths, even the holes are actually freestanding unclosed paths. Grrrrr.

- LaserWeb imports the ‘paths’, and ‘closes’ any paths that end up ‘on top of’ each other (I simplify a bit… it’s ‘complicated’).

- It can do ‘follow the line’ cuts on the standalone paths, but not ‘outline’ ones;

cut outside,cut inside,fill pathetc.

LaserWeb really should give better feedback about what has happened… for sure, it can go on the issue list. The main ‘generate gcode loop’ runs OK, it adds start and stop code, but none of the paths it can see are closed; so it just delivers an empty gcode body. This really should add some kind of console log; at least.

However; none of the above helps you. My best suggestion is to see if OneShape does a better job of exporting to .svg (if that is an option). LaserWeb does a better (though not perfect) job of closing paths with svg.

I was able to repair your file in InkScape; but it took a bit of work even for me (and I’m well-versed in InkScape) since all the standalone paths had to be ‘joined’ at the end nodes. The result is attached; and will properly generate Outside and Inside cuts, but re-working a file like this in Inkscape is a poor ‘solution’ for most people.

Maybe an online file ‘repair’ tool can help, there are quite a few online ‘svg generator and repair’ sites online. Most allow free casual use. Search these forums and elsewhere for them.

I use InkScape for all my 2d work these days; especially for ‘fixing’ files prior to cutting or engraving them. It’s ability to organise (and edit the organisation of) the image according to individual layers/groups/paths and nodes is really handy.

- My customary workflow for ‘parts’ with precise dimensions is to draw them at the correct size using OpenSCAD’s 2D tools; render that and export to

.svg. - If necessary I open it in InkScape since OpenSCAD outputs a single path; everything is properly ‘closed’ but you cannot select individual closed elements.

- This is fine for some jobs but not if you need to do different operations on different parts of the output.

- In inkscape I can automagically break this path into it’s components, and then group them into the cuts I want to make

- This is most useful when I have different cut and engrave actions on the same piece.

This works for me, and has forced me to learn InkScape in progressively more detail.

Svg below… it retains the same origin as the DXF file and therefore renders badly here but should be OK once downloaded (unless Discord munges it; I’m hoping it doesnt ![]() )

)

Part Studio 1 - Sketch

@easytarget thanks for the big explaination. I was figuring something like that happened, but knew no cause. If svg fixes it then i seek to continue with svg format.

Hope the cad programs i use will support the svg export, im gonna give that a try.

Thank you!

Today i tried some freecad and i actually managed to export a svg fairly easy and got it working as an inside and outside job on laserweb.

Then freecad/laserweb/mach3 is gonna be my toolchain to use.

Thanks for the support!