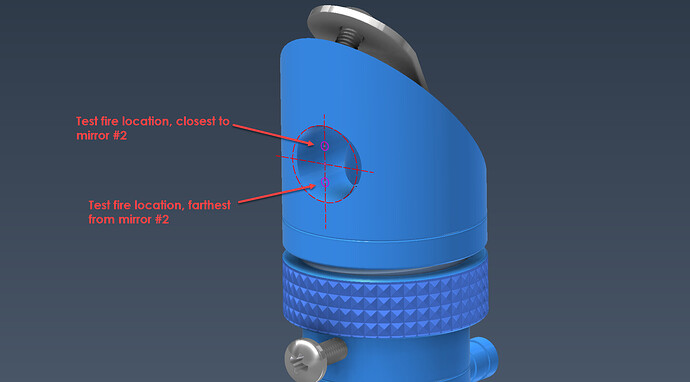

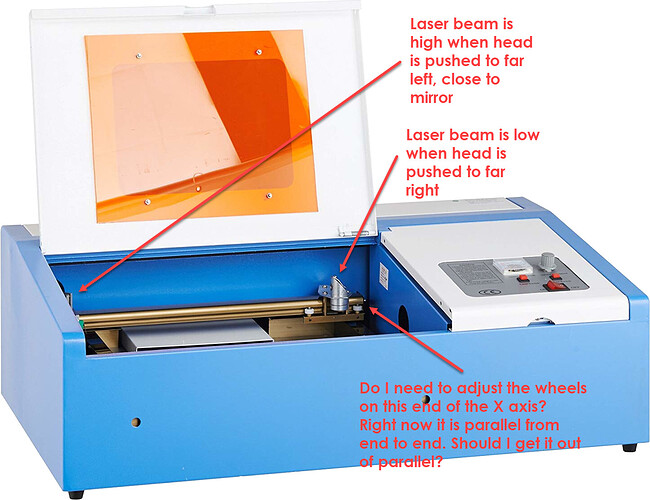

I’ve recently removed my stock K40 gantry, squared and aligned and re-installed. I did this because I was having an issue with circle roundness. I have fixed that issue but now I can not get my laser aligned so it’s dead center to my laser head. I have a good 3/16" between test fire dots from the head closest to mirror #2 to farthest away. Should I adjust the far side of my X axis wheels by either lowering or raising? I’m not sure I had this problem before I removed the gantry. Maybe I did but I don’t think it was as much as 3/16". I’m asking you folks because I don’t want to start adjusting the wrong thing. I’m frustrated with myself that I can’t quite get this right.

Not sure I fully grasp your problem.

Are you having a problem at the surface in terms of power or other issues driving you to get the beam on the center of mirror #3? Sometimes the optimum place for the beam is not the center.

I’m trying to get the beam on center. I’m wondering if I have a mechanical issue since I cannot adjust the mirrors just right.

My guess is your beam is not running parallel to the carriage.

Since it’s high on the left and low on the right I would guess that the beam is exiting mirror 2 from a high position and pointing downward.

Normally the wheels do not need adjusting and I would suggest keeping the head assembly parrallel until you have ruled out other possibilities.

This problem could originate at any reflecting surface including the laser being tilted up/down.

The carriage in these machines rarely are square and level and they compensate by tilting the laser which is a bad idea.

So because you corrected the carriage you may end up having to ensure the laser is parallel with the reset carriage.

I had a severe form of this problem which caused me to create these tools.

You may not need to create something this elaborate but the blog post will assist in understanding the problem.

IIRC you generally want to do what you did at the back of the machine(at Y=0) also doing it at the front of the machine(Y=MAX). If you get the same results that would be preferred since it means the frame mounts on the right side can be equally shimmed /adjusted.

my $0.02 is to adjust mirror #2 so you hit center on your laser head opening at Y=0(rear), X=0(left) and verify you also get center at Y=max(front), X=0(left). Then, look again at the X=max alignment and how far it is off will likely indicate how much you need to shim(+/-) on the right side frame mounts.

But read through this detailed instruction of the whole process so you can validate you have mirror #1 and #2 in a-OK shape: https://k40.se/k40-laser-lens-mirror/mirror-alignment/

Oh, and don’t use tape over those holes to get your laser spots unless you also put some foil or a US dime on the back so that the melted glue does not splatter onto your mirrors and make a real mess of things.

Thank-you for your input, Don. I took advantage of a snow day here in the Mid-West. Our business closed at 11am, so I went home, snow blowed, coffee, and headed down to the nerdery in my basement to figured this thing out. What I did was shim one corner of my gantry upward another .030". I then tackled the mirrors once more. I adjusted the 1st and 2nd mirrors and ended up closing the gap to about half of what it was. Still not perfect but satisfactory. I am cutting cleanly thru my material on all 4 extreme corners. Circles still look great. I could definitely keep tweaking but I’m calling this good for now.

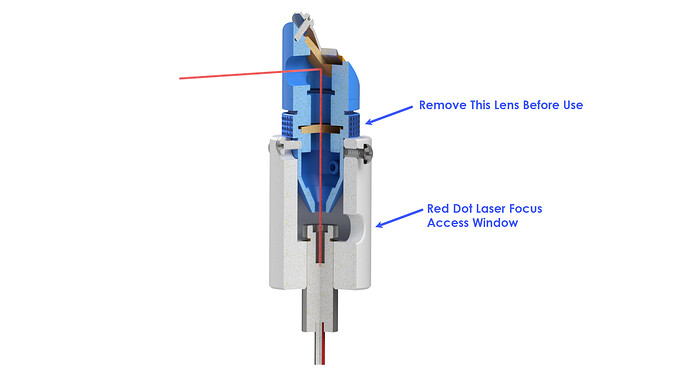

Yesterday I built a reverse laser with an extra red dot laser that I had lying around. I haven’t tried it yet but might dink with it a little.

The problem with this is it will probably not get you any closer to alignment. There is no possible way to align the led with the tubes x, y axes along with perpendicular (z axes). To get it right you have to align from the source (tube) to the worktable (surface).

I have a different head system and I can do an alignment in maybe 10min, usually less…

I don’t know how your m1 and m2 are configured, but i cut out targets (before I need them)… no stickem to gum up the works…

I’d suggest going over an alignment a few times to ensure there isn’t anything else wrong …

I think @donkjr has a good interpretation of the issue.

Did you check and see if the tube has been ‘shimmed’ at one end?

Do you only lose the alignment from m2 → m3?

![]()