Are you using something other than distilled water?

Think I’m ok now folks. Removed the tube and a close inspection reveals that there is a leak internally an some water has entered the gas chamber part of the tube. Thank you all for your guidance.

same story here, i has bougt also a new K40 and i has testing the machine on 20 % power for a veri small time without water cooling, resulting in a not working tube now, i see water in the discharge tube

i new istube ordered now

i am totaly new with CO2 lasers, so are there more inportant things that i should to know?

sorry for me englisch

greetings from Belgium

@Kitch be advised that the LPS is lethal [20,000Volts]. I would not advise disconnecting it and doing any testing with it live and not connected to the tube.

@wilver there is lots of K40 information on this forum start with the links up on the ribbon at the top of this forum.

Here is some more info. https://donsthings.blogspot.com/

The New to K40: Start Here post will get you started, and it links to content in the Getting Started with CO2 Lasers categorty. That category is moderated by some of our experts.

Always have water flowing through your tube and without bubbles in the tube before firing the tube for any length of time. People put water flow indicators above their machines just to make sure there’s water flowing and they often get them after they’d broken their tube by not having water flowing for one reason or another and turning on the laser power. ie after learning the hard way.

… and or add a flow sensor into the interlock circuit… that is what WP means water protect

hi there

thanks for the answer

i have a new question

what is the distance between the tube output and the first mirror?

thanks

I can go measure but curious why you want to know.

i bought a new K40 but the tube is broken(transport??) so i has to placing a new tube and i will know the distance(maby that distance is important? )for adjusting the mirrors

thanks Sir

In my machine, the end of the tube is about 1" to the center of the first mirror. That distance is not important.

What is most important is that the laser is parallel to the x-axis of the carriage. Then realign all the optics to that position.

I would mark the current lasers bracket’s mounting position as a starting point.

if the cooling water passes through the tube, should the tube be completely filled with water? with my tube I see that the tube is only filled to half the diameter, I have no air bubbles and the cooling water flows very well

before I control my laser I want to be sure if it is normal that the tube is only filled to half the diameter with water

sorry for this question, i am just started with CO2 lasers

There should be FAR more water in the tube than half way and I would not fire the laser with that setup. Since you are new to the K40 and CO2 lasers I HIGHLY recommend you read all of the K40 Info here( New to K40: Start Here ) and all of the K40 Quick Help here( https://k40.se/# ).

I could not find on either site the specifics of water filling the tube so here is what I found about “bubbles” in the tube at this site( What are the air bubbles in the CO2 laser tube and what to do to avoid them?-Bunny | XTLASER )

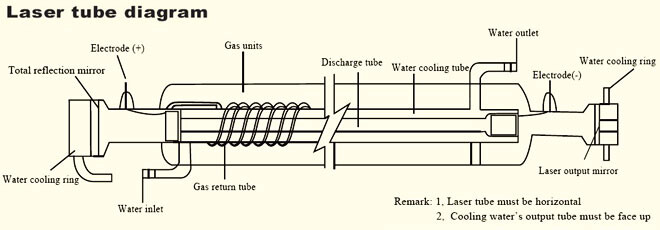

By rotating the laser tube so that the water outlet is the highest point of the cooling loop. This will prevent air bubbles from forming around the cavity of the reflecting mirror.

It just dawned on me that you might be seeing water in the outer casing of the laser tube… There should be no water in the outer case of the laser tube. Only the inner tube section:

also seen in this video:

works great now with the new tube

and now it’s time to setting the mirrors, looks also a big challenge; i gues

That is discussed in the FAQ’s I linked previously. And if you have a ‘digital’ display you want to get an analog meter so you don’t burn out this new tube too soon… Again, touched on in the FAQs.

I’ve been running since start of winter with a 50% solution of distilled water and propylene glycol, the flow is always full of bubbles. Have run a bunch of hours. The glycol reduced the flow rate. Temperature seems to be about the same…

These bubbles flow… What you don’t want is a bubble that ‘sticks’ to an area of the tube that needs to be cooled…

![]()

Well, you might not have problems running like that but it’s not recommended people run a setup which generates bubbles and constantly flows bubbles through the system. At that point you’re then going down the rabbit hole of all the variations of tubing configurations and inlet and exit locations causing air pockets etc.

Nice that you’re able to work with that and not have problems and have acceptable heat transfer with so much air in the lines. Not what I would show anyone who’s not been around the block with these things for less than a year or so.

So what’s causing the bubbles? Do you have the return exit hose dumping above the water line instead of below water line/level? Do you have a leak in your line somewhere so air is being pulled into the line somewhere?

The mixture of the glycol going through the pump causes bubbles.

I have a 5202 chiller, no leaks, just the addition of the glycol. All ‘plumbing’ coming out of the tube is oriented properly. The only other thing in the ‘line’ is a flow meter. It was present and working before the glycol addition, so that’s not an issue.

I sent that video to Russ Sadler, back when I did it, and he said it wasn’t a problem. He has a tad more expertise in this than I. As I questioned the bubbles issue also.

I’ve been running it, at about 16ma - pretty hard, in just the last couple of weeks cutting 4.6mm ply.

I have mA , HV, coolant temp & flow rate meters…

The glycol thickens the mixture, resulting in a slower flow rate.

The tradeoff is that it has a good dielectric constant and at 50%, is good to 15 F for freeze protection. Seemed like a good tradeoff for freeze protection…

I love critters, with most antifreeze mixtures being sweet and toxic to most animals…

I buy it at the tack shop… for milk cows… so you can eat it ![]()

![]()

Is the pump submerged in the return tank AND is the return line below the waterline so as to not add air to the system?

Also surprised Russ didn’t mention added a little bit of Dawn dish detergent to break surface tension and eliminate air bubbles. The technique is used in glycol based solar systems specifically for air bubble removal.