I’m working on the design for the Y belt clamps. In most designs I like the belt tensioner on the belt clamp, but it is becomming apparent that the existing mounting holes for the Prusa i2 and Prusa i3 belt clamps will not allow enough room for that. I am contemplating on putting either the Y motor or Y idler on sliding slots to allow for belt tensioning. This would make belt tensioning more accessible. Currently the idler has the mounting nut for the bearing go through the piece, and mount to a nut that would fit inside the extrusion slot, hopefully providing for better holding of the bearing to prevent torsion. If I were to make the idler adjustable, this would need to change, and I fear it may impact the ability of the idler bearing.

If i were to put the slots on the motor mount, it will take up more material, and I worry it can affect the motor mount strength.

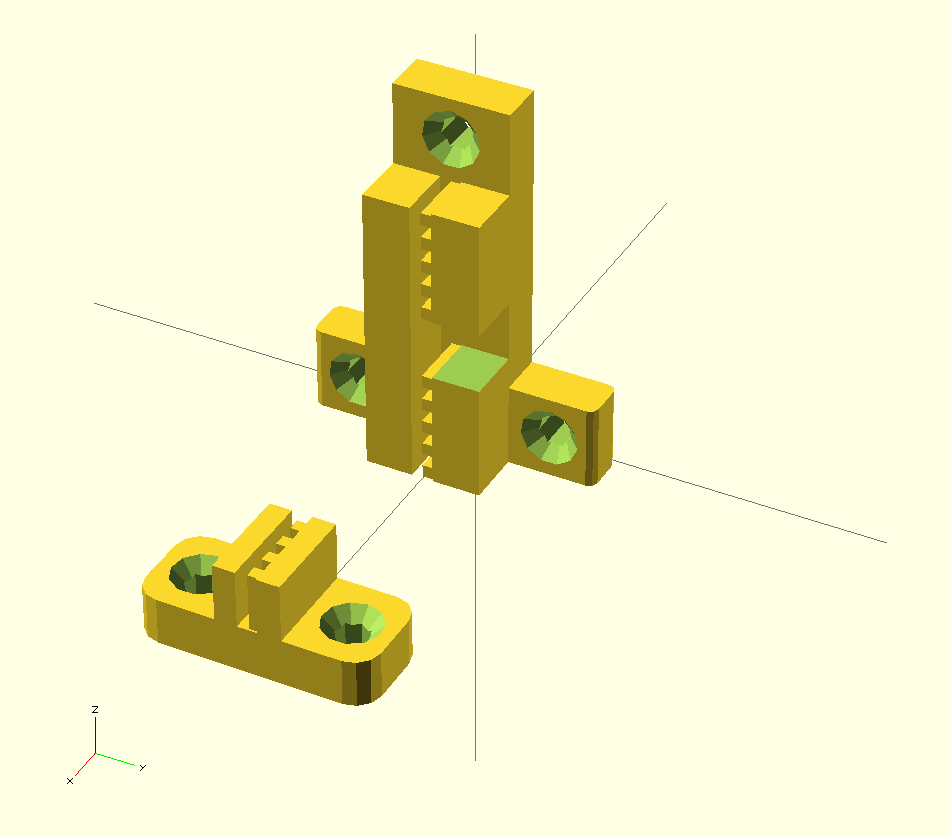

Attached is an image of the two types of belt clamps.

Belt tensioning: 3 zipties. Loop 2 ends of the belt, put a ziptie between them. Belt gets loose? Pull the ziptie.

Like this: http://3.bp.blogspot.com/-YR4PGydCYHo/UIT8CCnTnvI/AAAAAAAAAIs/7a81b_d3AUs/s1600/belt_tensioner.jpg

@ThantiK Its rigid enough? When I tried it, I could not make it rigid enough and it introduced lots of backlash

@Vaclav_Hula I have used this method for over a year. I could play the banjo on my belts. I regularly break 180mm/s travel speeds. If you weren’t able to make it rigid enough, the problem you were having is likely elsewhere (binding on the axis, etc)

A printable solution would be preferable. Good solution though, I’ll leave that option open.

I tried the Prusa i3 variant. Would not hold my belts. Looks good though if only I could get it to work. Returned to Zipties. At each belt end I loop it with a Ziptie and fasten it to the carriage with another one. Easy to fasten and very easy to get the right tension.

@Tom_Oyvind_Hogstad the prusa i3 notched belt holders are really nice. Did you generate the proper toothed profiles for your belt in the configuration.scad?

@ThantiK To be honest, I have not tested printed profile for gt2 2mm - that may not work. But for t2.5 and bigger its quite nice

I have GT2 belts and I changed to the right one in the scad. Pulled the latest sources from github that had support for GT2. The GT2 belts are very soft …

@Vaclav_Hula I use MXL, which is just as small of a profile as GT2, and they work amazing. Printed with 0.5mm nozzle. I can tell you for sure…they work.

I think the belts was to thin. E.g. Too much space in the holder.

@Tom_Oyvind_Hogstad Yea, some love for belts is still needed in i3. When current update is in the wild (there is pull request waiting for some people to check the models) there is belt rework in the queue (support for parametric belt width and thickness, new tensioning idler on X axis, x-carriage simplification)