I’m thinking of experimenting with reinforcing my X and Y axis with steel angle. Anyone ever done this? It’s pretty cheap from Home Depot.

Im working on a machine right now with a steel c channel gantry. I have done a lot of thinking and experiments with bolting c beam together, but couldn’t achieve enough rigidity still. I was going to try using steel to reinforce, but abandoned that idea and am just moving to a rock solid gantry with thk style linear rails and blocks

Right now the most flexible part of my machine is the x axis gantry plates. I have considered stiffening the plates by bolting on some angle.

@Colin_Kaminski did you do anything with your z axis? I want to stiffen all my axis up but with the R7z mod when I do aluminum I get better results if I stack some MDF up to bring my Z closer to stock. Is this flex in the X? I figured it was Z flex.

I have a riser that is 16x30x4 that I often use for plate. The Z-axis flex is the durometer of the wheels as far as I can tell. It is amplified by the extra distance from the wheels to the table in the R7z mod. I find it makes me take lighter cuts but it doesn’t cause ringing/chatter. If however I put plate on the table and climb cut a large diameter circle I get some ringing at 1:30 and 7:30. This, as far as I can tell, is the x-axis gantry plates ringing.

Hard to see in that pic, but it worked well in this application

Hi all!

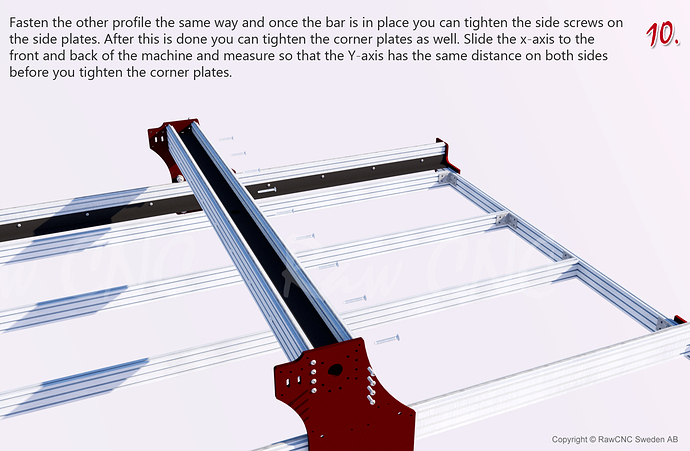

I saw that RAWCNC XL design also uses a square steel pipe between two aluminum profiles in the gantry for rigidity, and also for the longer axis uses angle steel.