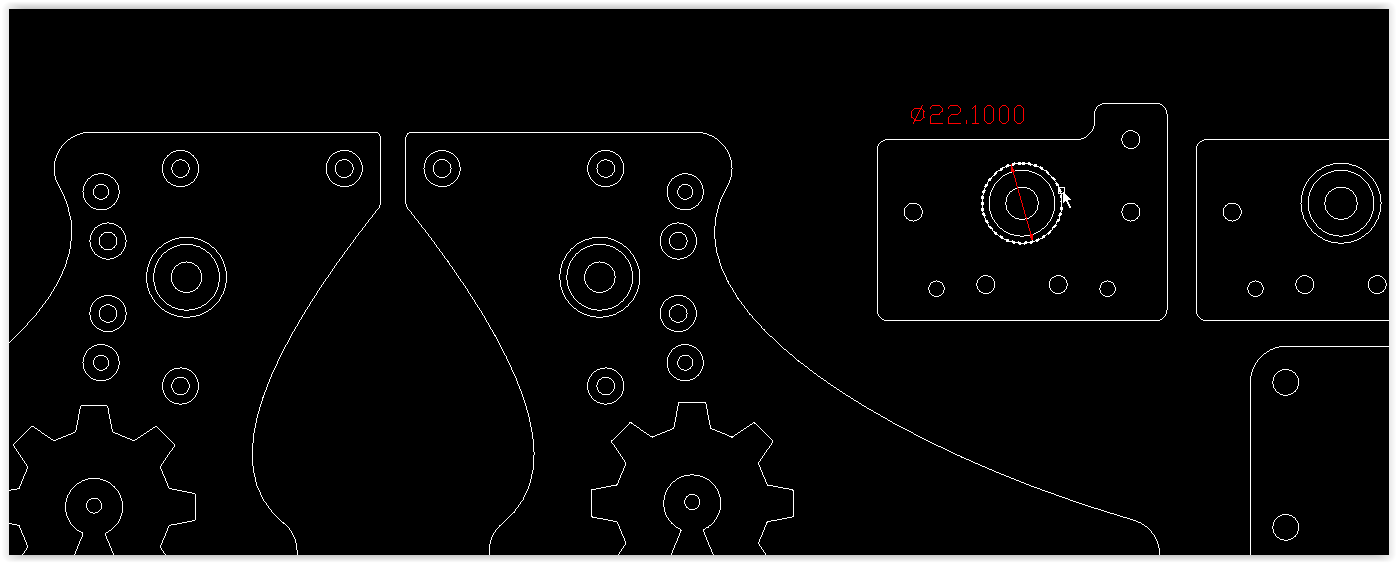

I just did the R7z mod and it has turned out well. However, a question; both the R7z and R7 CAD models have the bearing block as .866", using 608Z bearings. .866 is 21.99mm and 608Z bearings are 22mm. Between the tolerances machining the bearing block and the tolerances of 608Z, they just barely don’t fit. I had to take a 22mm reamer to get it to fit snug. Is there a reason for this that I am missing?

Mind sharing where you are seeing that dimension? Picture and file?

For the R7z, from Colin’s google drive @ https://drive.google.com/drive/folders/1FX5XazvT9ItUI95aqDxH0pj5qSuOnfE7

I adjusted my tool paths to cut 20.04mm by changing the “material to leave” parameter to a negative number. I did this cut at the drawing dimension then measured and cut again to make sure the bearings were snug fit. Not quite press fit but tighter than slip fit.

@Colin_Kaminski Thanks that makes sense now. I redid all the toolpaths to cut one plate at a time as well as switch to a 1/8 bit. I did not notice the material to leave parameter so left that off. The reamer made it fit fine, just wanted to make sure I wasn’t missing something with my pocket being slightly smaller.

I just looked, the original model has it at 22.1mm. Same with the DXF plate files Brandon made available back in the beta phase.

One thing to note is a caliper is the wrong tool to measure an ID accurately. I am not knocking, because I use the tools I have available too. But getting a repeatable/accurate measurement for an aluminum ID hole with hard jawed calipers… it can lead to undersized measurements. It’s near impossible to rock into the apex of both sides without catching leading to undersized measurements.

I wish I had a snap bore gauge.