I developed this for my Geeetech 3D printer, but it may be an inspiration for other delta owners.

Originally shared by Jason McMullan

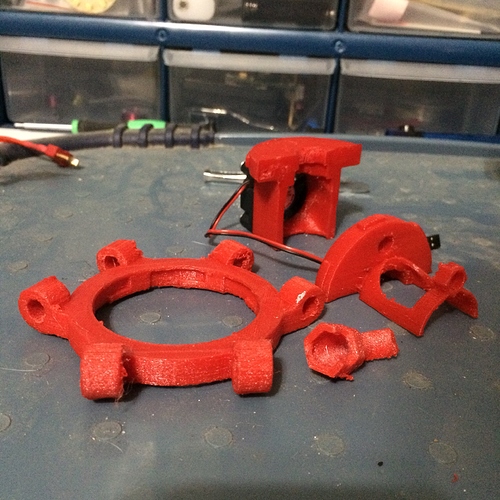

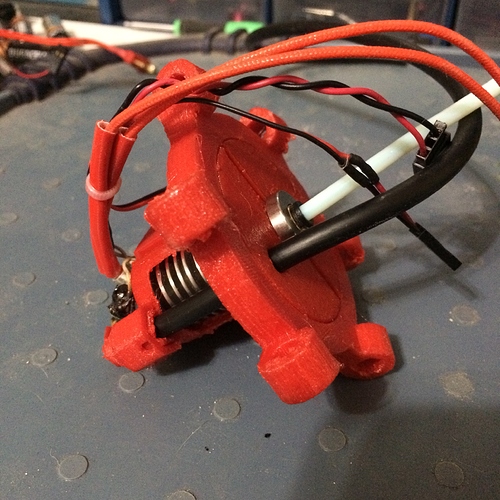

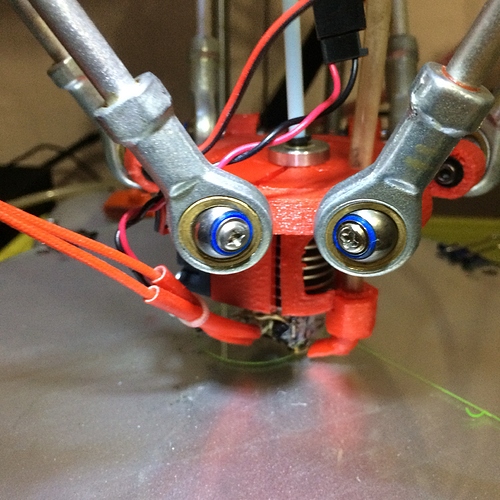

My twist-lock effector development slowly continues.

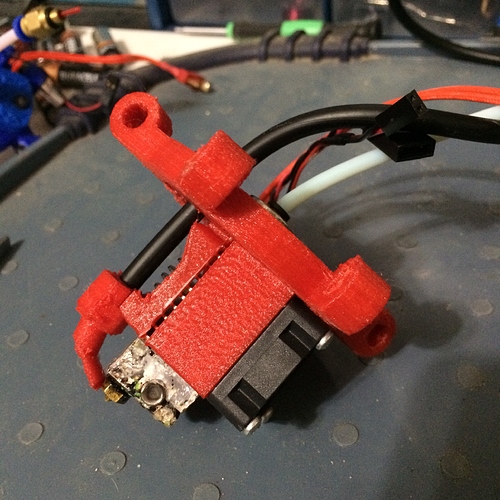

I’m now using a 6-notched twist lock, instead of the older cam-in-hole style, and abandoned the fan-above-the-effector style for now.

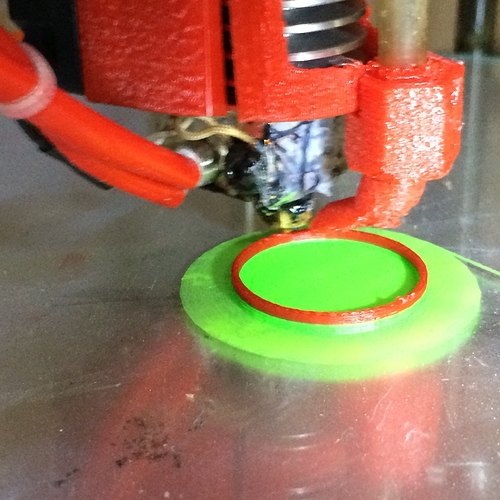

Nozzle cooling for PLA printing is done with a airline to an aquarium air pump - it’s surprisingly effective, and reduces on-effector weight.

Calibration needs to be done, but a quick test shows that it doesn’t immediately fall apart or unlock during printing.

For easier printability of the effector - and for quick replacement if it melts - the airline “foot” is a snap-on part.