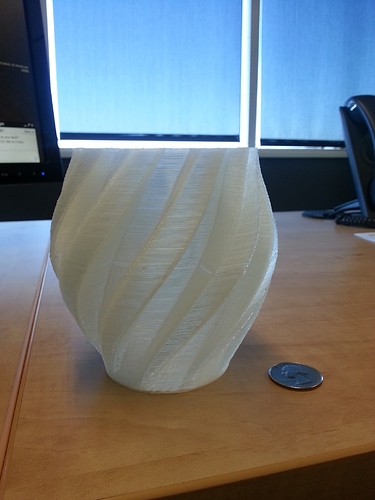

I calibrated my extruder (apparently that makes a difference  Went from 569 to 519, thanks @Alberto_Valero_Gomez ) and extruded at 195 degrees (thanks @Nils_Hitze ). Aside from a filament snarl issue about 3/5 through the print (http://www.thingiverse.com/thing:31722), I think it turned out fairly nice. Still a lot of room for improvement, but I’m feeling good for my second day of printing on my Printrbot Jr!

Went from 569 to 519, thanks @Alberto_Valero_Gomez ) and extruded at 195 degrees (thanks @Nils_Hitze ). Aside from a filament snarl issue about 3/5 through the print (http://www.thingiverse.com/thing:31722), I think it turned out fairly nice. Still a lot of room for improvement, but I’m feeling good for my second day of printing on my Printrbot Jr!

I agree @Jeff_Karpinski . I’m going to spend tonight further calibrating it, as well as trying to tweak it for speed  The vase/lamp took around 3 hours at 0.4mm layer height and walls 3 layers thick, I know the Jr. is capable of printing faster than that, just need to figure out how to get there!

The vase/lamp took around 3 hours at 0.4mm layer height and walls 3 layers thick, I know the Jr. is capable of printing faster than that, just need to figure out how to get there!

What filament did you use? My prusa can make a lot better quality but only with the right filament. I found faberdashery giving me the best results.

Just the stuff that came with the Jr, (http://printrbot.com/shop/1lb-1-75mm-pla/). I just placed an order for some PLA and Nylon filament from MatterHackers since they offer free shipping in the US. I’m hoping that will be here next week so I can play with it.

Watch the fumes on that nylon. Is the Ubis hot end rated high enough to work with nylon? Can’t remember temps and too lazy to look it up in my phone right now.

How bad are the fumes relative to ABS? I hadn’t even thought to look into whether or not the Ubis can handle it  EDIT: Uffda, just looked at the recommended printing temp for Nylon: 320C

EDIT: Uffda, just looked at the recommended printing temp for Nylon: 320C

Deadly…

Ok, well, looks like I’ll just be sitting on that filament for a while and stick to my PLA.

Actually after looking into it on the manufacturer’s website (http://www.taulman3d.com/specifications.html), I think I’ll be able to use it just fine.

“2. 618’s bonding is best at a true 245C.

3. You may have heard nylon emits fumes while printing. 618 does not emit any fumes for printing. Actually, there is no odor at all from 618. You may see what looks like puffs of smoke, but it is actually water vapor or steam.”

Yes, Taulman has tested for one specific toxic gas (HCL). However, there are many other obnoxious gases that may be released from Nylon, many of which are odorless. So the does not emit any fumes argument is totally moot.

And the quality of your PEEK barrel and your thermistor on the Ubis hot end may come into play. I’ve seen numbers for PEEKs transition point being as low as 279c which if you have a poor PEEK barrel and a thermistor that is off you may think you’re hitting 245 and be approaching 270… Don’t want you to kill yourself or wreak your new machine

At 270-ish degrees the PEEK barrier and the Nylon fumes are the least of your worries - almost all hotends are still lined with PTFE, which will easily get a kink at those temperatures and block your hotend. It will also start to decompose into toxic fumes that are magnitudes deadlier than those released from the Nylon.

I completely forgot about the PTFE. I can confirm the Ubis hot end uses it too. Had to rebuild part of it once.

If and when this http://prusanozzle.org/ becomes a purchasable thing, I might try Nylon. Not til then. Definitely would not try it with my printrbot’s Ubis. I like my hotend working - but I’ve got many of the bits for a new printer - I’ve actually got a hotend for it, from a Kickstarter, but I’ve been watching prusanozzle precisely because of the possibility of having a wider variety of usable plastics.

Unfortunately, the website says “Expected availability week-50 2012” and it is now 2013, and I’ve seen nothing in my email from that newsletter.

I asked him that same exact question a couple of days ago and it turned out that he was having trouble mass-producing the hotends.