Can anybody help with this, every thing works as it should apart from homing. When I issue G28 the endstops are hit but there seems to be no retract and the machine stops with Pronterface reporting Error: Rotary delta illegal move, Reset or $X or M999 required.

ERROR : Homing cycle failed-- check Max travel settings.

Max travel settings do not seem to alter anything, I have tried setting from 50 to 1000 with no difference in outcome. Any pointers would be very welcome.

( I have the endstop setup from config but cannot find how to upload it)

We need a few more details to help. What printer hardware configuration are you running, what controller (firmware), what is the current configuration on the printer. Etc.

Let us know that info and we can proceed from there.

THANKS Eclsnowman, I thought the upload button above was to put the comment in the conversation.

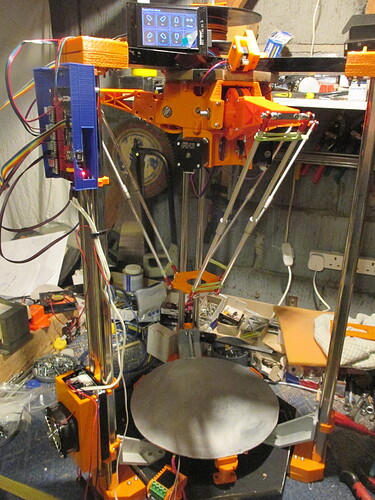

Hardware configuration is firepick type layout ( hope the photo is clear enough). At the moment I’m using a spare SKR V1.3 board I had because it will run smoothie and the touch screen I’ve lifted off another printer to try this machine. If I can get it running successfully I will change it for a smoothie board so that I can use the wifi.

# NOTE Lines must not exceed 132 characters

# Robot module configurations : general handling of movement G-codes and slicing into moves

default_feed_rate 4000 # Default rate ( mm/minute ) for G1/G2/G3 moves

default_seek_rate 4000 # Default rate ( mm/minute ) for G0 moves

mm_per_arc_segment 0 # Fixed length for line segments that divide arcs 0 to disable (ñòàðîå çíà÷åíèå 0,2)

mm_max_arc_error 0.01 # The maximum error for line segments that divide arcs 0 to disable

# note it is invalid for both the above be 0

# if both are used, will use largest segment length based on radius

#mm_per_line_segment 0.2 # Lines can be cut into segments ( not useful with cartesian

# coordinates robots ).

delta_segments_per_second 150 # for deltas only same as in Marlin/Delta, set to 0 to disable

# and use mm_per_line_segment

# Arm solution configuration : Rotatable Delta robot. Translates mm positions into stepper positions

arm_solution rotary_delta # selects the delta arm solution

delta_e 152.767 # End effector length, triangle side length in mm

delta_f 270.200 # Base length, triangle side length in mm

delta_re 320.000 # Carbon rod length {370.00}

delta_rf 170.000 # Servo horn length

delta_z_offset 350.200 # Distance from big pulley shaft to table/bed { }

delta_ee_offs 4.300 # Ball joint plane to bottom of end effector surface

delta_tool_offset 20.000 # Distance between end effector ball joint plane and tip of tool (PnP)

rotary_delta_calibration.enable true

#The steps per degree are calculated as:

# For Firepick delta robot:

# (1) First determine the circumference of the big pulley, which has a smooth surface, and calculate the 'teeth it would have'

# (2) Determine the GT2 belt thickness and tooth depth

# (3) Calculate the ACTUAL big pulley circumference taking into account that the GT2 belt affects this as

# it rests on the big pulley and not into teeth cut into the pulley, the formula is:

# BIG_PULLEY_CIRCUMFERENCE = BIG_PULLEY_TEETH * TOOTH_SPACING + (BELT_THICKNESS - TOOTH_DEPTH)*6.283185

# (4) Calculate the ACTUAL small pulley circumference taking into account that the GT2 belt affects this as

# rests into the small pulley as it has teeth cut into the pulley, the formula is:

# SMALL_PULLEY_CIRCUMFERENCE = SMALL_PULLEY_TEETH * TOOTH_SPACING

# (5) Now determine the pulley reduction which is:

# PULLEY_REDUCTION = BIG_PULLEY_CIRCUMFERENCE / SMALL_PULLEY_CIRCUMFERENCE

# (6) Finally, given the number of steps a stepper motor needs for a full 360 degree rotation, and the number of microsteps your

# stepper motor driver chip is set for, you can calculate the STEPS_PER_MM for each axis, which for a Rotary Delta, are the same:

# [ALPHA/BETA/GAMMA]_STEPS_PER_MM = (XYZ_STEPS_PER_ROTATION*XYZ_MICROSTEPS*PULLEY_REDUCTION)/360

# e.g. a FirePick Delta mechanism, we can calulate:

# BIG_PULLEY_CIRCUMFERENCE = 150 * 2 + (1.49 - 0.74) * 6.283185 = 304.712389

# SMALL_PULLEY_CIRCUMFERENCE = 16 * 2 = 32

# PULLEY_REDUCTION = 304.712389 / 32 = 9.52226215

# For a 0.9 degree stepper motor and an a4988 driver set for 16 microsteps = (400 * 16 * 9.52226215)/360 = 169.2846604

# For a 1.8 degree stepper motor and an a4988 driver set for 16 microsteps = (200 * 16 * 9.52226215)/360 = 84.6423302

# For a 0.9 degree stepper motor and an drv8825 driver set for 32 microsteps = (400 * 32 * 9.52226215)/360 = 338.5693208

# For a 1.8 degree stepper motor and an drv8825 driver set for 32 microsteps = (200 * 32 * 9.52226215)/360 = 169.2846604

alpha_steps_per_mm 714.6666 # Steps per degree for alpha stepper

beta_steps_per_mm 714.6666 # Steps per degree for beta stepper

gamma_steps_per_mm 714.6666 # Steps per degree for gamma stepper

# Planner module configuration : Look-ahead and acceleration configuration

planner_queue_size 32 # DO NOT CHANGE THIS UNLESS YOU KNOW EXACTLY WHAT YOU ARE DOING

acceleration 1000 # Acceleration in mm/second/second.

junction_deviation 0.05 # Similar to the old "max_jerk", in millimeters,

# see https://github.com/grbl/grbl/blob/master/planner.c#L409

# and https://github.com/grbl/grbl/wiki/Configuring-Grbl-v0.8

# Lower values mean being more careful, higher values means being

# faster and have more jerk

#minimum_planner_speed 0.0 # sets the minimum planner speed in mm/sec

# Stepper module configuration

microseconds_per_step_pulse 1 # Duration of step pulses to stepper drivers, in microseconds

base_stepping_frequency 100000 # Base frequency for stepping

# Cartesian axis speed limits

x_axis_max_speed 30000 # mm/min

y_axis_max_speed 30000 # mm/min

z_axis_max_speed 30000 # mm/min

# Stepper module pins ( ports, and pin numbers, appending "!" to the number will invert a pin )

alpha_step_pin 2.2 # Pin for alpha stepper step signal

alpha_dir_pin 2.6! # Pin for alpha stepper direction

alpha_en_pin 2.1 # Pin for alpha enable pin

alpha_current 0.8 # X stepper motor current

alpha_max_rate 30000.0 # mm/min

alpha_max_travel 1000 # max travel in mm for alpha/X axis when homing

beta_step_pin 0.19 # Pin for beta stepper step signal

beta_dir_pin 0.20! # Pin for beta stepper direction

beta_en_pin 2.8 # Pin for beta enable

beta_current 0.8 # Y stepper motor current

beta_max_rate 30000.0 # mm/min

beta_max_travel 1000 # max travel in mm for beta/Y axis when homing

gamma_step_pin 0.22 # Pin for gamma stepper step signal

gamma_dir_pin 2.11! # Pin for gamma stepper direction

gamma_en_pin 0.21 # Pin for gamma enable

gamma_current 0.8 # Z stepper motor current

gamma_max_rate 30000.0 # mm/min

gamma_max_travel 252.000 # max travel in mm for gamma/Z axis when homing (max homing for a delta)

# Serial communications configuration ( baud rate default to 9600 if undefined )

uart0.baud_rate 115200 # Baud rate for the default hardware serial port

second_usb_serial_enable false # This enables a second usb serial port (to have both pronterface

# and a terminal connected)

#leds_disable true # disable using leds after config loaded

#msd_disable false # disable the MSD (USB SDCARD) when set to true

#dfu_enable false # for linux developers, set to true to enable DFU

#watchdog_timeout 10 # watchdog timeout in seconds, default is 10, set to 0 to disable the watchdog

# Extruder module configuration

extruder.hotend.enable true # Whether to activate the extruder module at all. All configuration is ignored if false

extruder.hotend.steps_per_mm 98.100 # Steps per mm for extruder stepper

extruder.hotend.default_feed_rate 600 # Default rate ( mm/minute ) for moves where only the extruder moves

extruder.hotend.acceleration 500 # Acceleration for the stepper motor, as of 0.6, arbitrary ratio

extruder.hotend.max_speed 50 # mm/s

extruder.hotend.step_pin 2.13 # Pin for extruder step signal

extruder.hotend.dir_pin 0.11 # Pin for extruder dir signal

extruder.hotend.en_pin 2.12 # Pin for extruder enable signal

# extruder offset

#extruder.hotend.x_offset 0 # x offset from origin in mm

#extruder.hotend.y_offset 0 # y offset from origin in mm

#extruder.hotend.z_offset 0 # z offset from origin in mm

# firmware retract settings when using G10/G11, these are the defaults if not defined, must be defined for each extruder if not using the defaults

#extruder.hotend.retract_length 4 # retract length in mm

#extruder.hotend.retract_feedrate 50 # retract feedrate in mm/sec

#extruder.hotend.retract_recover_length 0 # additional length for recover

#extruder.hotend.retract_recover_feedrate 8 # recover feedrate in mm/sec (should be less than retract feedrate)

#extruder.hotend.retract_zlift_length 0 # zlift on retract in mm, 0 disables

#extruder.hotend.retract_zlift_feedrate 6000 # zlift feedrate in mm/min (Note mm/min NOT mm/sec)

delta_current 1.0 # First extruder stepper motor current

# Hotend temperature control configuration

temperature_control.hotend.enable true # Whether to activate this ( "hotend" ) module at all.

# All configuration is ignored if false.

temperature_control.hotend.thermistor_pin 0.24 # Pin for the thermistor to read

temperature_control.hotend.heater_pin 2.7 # Pin that controls the heater

temperature_control.hotend.thermistor Semitec # see http://smoothieware.org/temperaturecontrol#toc5 Semitec

#temperature_control.hotend.beta 4066 # or set the beta value

temperature_control.hotend.set_m_code 104 #

temperature_control.hotend.set_and_wait_m_code 109 #

temperature_control.hotend.designator T #

temperature_control.hotend.max_temp 255

# Set maximum temperature - Will prevent heating above 300 by default

temperature_control.hotend.min_temp 0 # Set minimum temperature - Will prevent heating below 0 by default

temperature_control.hotend.p_factor 27.6 # permanently set the PID values after an auto pid

temperature_control.hotend.i_factor 1.612 #14.12 1.42 35.00

temperature_control.hotend.d_factor 199.00 #

temperature_control.hotend.max_pwm 255 # max pwm, 64 is a good value if driving a 12v resistor with 24v.

# Hotend2 temperature control configuration

#temperature_control.hotend2.enable false # Whether to activate this ( "hotend" ) module at all.

# All configuration is ignored if false.

temperature_control.bed.enable true #

temperature_control.bed.thermistor_pin 0.23 #

temperature_control.bed.heater_pin 2.5 #

temperature_control.bed.thermistor EPCOS100K

# see http://smoothieware.org/temperaturecontrol#toc5

#temperature_control.bed.beta 4066 # or set the beta value

temperature_control.bed.set_m_code 140 #

temperature_control.bed.set_and_wait_m_code 190 #

temperature_control.bed.designator B #

#temperature_control.bed.bang_bang false # set to true to use bang bang control rather than PID

#temperature_control.bed.hysteresis 2.0 # set to the temperature in degrees C to use as hysteresis

temperature_control.bed.p_factor 257.4 # permanently set the PID values after an auto pid

temperature_control.bed.i_factor 16.111 #773.50 147.53 1013.87

temperature_control.bed.d_factor 1028.0

# when using bang bang

# Switch module for fan control

switch.fan.enable false #

switch.fan.input_on_command M106 #

switch.fan.input_off_command M107 #

switch.fan.output_pin nc #

switch.fan.output_type pwm # pwm output settable with S parameter in the input_on_comand

#switch.fan.max_pwm 255 # set max pwm for the pin default is 255

#switch.misc.enable false #

#switch.misc.input_on_command M42 #

#switch.misc.input_off_command M43 #

#switch.misc.output_pin nc #

#switch.misc.output_type digital # just an on or off pin

# automatically toggle a switch at a specified temperature. Different ones of these may be defined to monitor different temperatures and switch different swithxes

# useful to turn on a fan or water pump to cool the hotend

#temperatureswitch.hotend.enable false #

#temperatureswitch.hotend.designator T # first character of the temperature control designator to use as the temperature sensor to monitor

#temperatureswitch.hotend.switch misc # select which switch to use, matches the name of the defined switch

#temperatureswitch.hotend.threshold_temp 60.0 # temperature to turn on (if rising) or off the switch

#temperatureswitch.hotend.heatup_poll 15 # poll heatup at 15 sec intervals

#temperatureswitch.hotend.cooldown_poll 60 # poll cooldown at 60 sec intervals

# Switch module for spindle control

#switch.spindle.enable false #

# Endstops

endstops_enable true # the endstop module is enabled by default and can be disabled here

delta_homing true # forces all three axis to home a the same time regardless of

# what is specified in G28

alpha_min_endstop nc #

alpha_max_endstop 1.28!^ # add ! to invert pullup if switch is NO to ground

alpha_homing_direction home_to_max # Home up

alpha_max 0 #

beta_min_endstop nc #

beta_max_endstop 1.26!^ #

beta_homing_direction home_to_max #

beta_max 0 #

gamma_min_endstop nc #

gamma_max_endstop 1.24!^ #

gamma_homing_direction home_to_max #

gamma_max 252.000 #

alpha_fast_homing_rate_mm_s 50 # homing feedrates in mm/second

beta_fast_homing_rate_mm_s 50 #

gamma_fast_homing_rate_mm_s 50

#

alpha_slow_homing_rate_mm_s 10 #

beta_slow_homing_rate_mm_s 10 #

gamma_slow_homing_rate_mm_s 10

alpha_homing_retract_mm 2 # retract/bounce distance after homing in mm

beta_homing_retract_mm 2 #

gamma_homing_retract_mm 2 #

alpha_trim 0 # software trim for alpha stepper endstop (in mm)

beta_trim 0 # software trim for beta stepper endstop (in mm)

gamma_trim 0 # software trim for gamma stepper endstop (in mm)

# optional enable limit switches, actions will stop if any enabled limit switch is triggered (all are set for delta)

alpha_limit_enable false # set to true to enable X min and max limit switches

beta_limit_enable false # set to true to enable Y min and max limit switches

gamma_limit_enable false # set to true to enable Z min and max limit switches

#homing_order XYZ

move_to_origin_after_home true # move XY to 0,0 after homing

#endstop_debounce_count 100 # uncomment if you get noise on your endstops

## Z-probe

# See http://smoothieware.org/zprobe

zprobe.enable false # Set to true to enable a zprobe

zprobe.probe_pin nc # Pin probe is attached to, if NC remove the !

zprobe.slow_feedrate 5 # Mm/sec probe feed rate

#zprobe.debounce_ms 1 # Set if noisy

zprobe.fast_feedrate 80 # Move feedrate mm/sec

zprobe.probe_height 20 # How much above bed to start probe

#gamma_min_endstop nc # Normally 1.28. Change to nc to prevent conflict,

# Levelling strategy

# Example for the delta calibration strategy

leveling-strategy.delta-calibration.enable false # Enable basic delta calibration

leveling-strategy.delta-calibration.radius 70 # the probe radius

# Example for the delta grid leveling strategy

leveling-strategy.delta-grid.enable false # Enable grid leveling

leveling-strategy.delta-grid.radius 70 # Grid radius in millimeters

leveling-strategy.delta-grid.size 3 # Grid size, must be an odd number

leveling-strategy.delta-grid.do_home false # Whether to home before calibration

leveling-strategy.delta-grid.save false # Whether to automatically save the grid

leveling-strategy.delta-grid.initial_height 30 # Height at which to start probling

leveling-strategy.delta-grid.probe_offsets 0,-34,0 # probe offsets x,y,z (Z should always be 0)

# kill button (used to be called pause) maybe assigned to a different pin, set to the onboard pin by default

kill_button_enable false # set to true to enable a kill button

#kill_button_pin # kill button pin. default is same as pause button 2.12 (2.11 is another good choice)

# Panel

panel.enable true

# set to true to enable the panel code

panel.lcd reprap_discount_glcd # set type of panel

panel.encoder_a_pin 3.25!^ # encoder pin

panel.encoder_b_pin 3.26!^ # encoder pin

# Example for reprap discount GLCD

# on glcd EXP1 is to left and EXP2 is to right, pin 1 is bottom left, pin 2 is top left etc.

# +5v is EXP1 pin 10, Gnd is EXP1 pin 9

panel.lcd reprap_discount_glcd #

panel.spi_channel 0 # spi channel to use ; GLCD EXP1 Pins 3,5 (MOSI, SCLK)

panel.spi_cs_pin 0.16 # spi chip select ; GLCD EXP1 Pin 4

panel.encoder_a_pin 3.25!^ # encoder pin ; GLCD EXP2 Pin 3

panel.encoder_b_pin 3.26!^ # encoder pin ; GLCD EXP2 Pin 5

panel.click_button_pin 0.28!^ # click button ; GLCD EXP1 Pin 2

panel.buzz_pin 1.30 # pin for buzzer ; GLCD EXP1 Pin 1 (1,31)

#panel.button_pause_pin 2.11^ # kill/pause ; GLCD EXP2 Pin 8 either

#panel.back_button_pin 2.11!^ # back button ; GLCD EXP2 Pin 8 or (2.11!^)

# pins used with other panels

#panel.up_button_pin 0.1! # up button if used

#panel.down_button_pin 0.0! # down button if used

#panel.click_button_pin 0.18! # click button if used

panel.menu_offset 0 # some panels will need 1 here

panel.alpha_jog_feedrate 6000 # x jogging feedrate in mm/min

panel.beta_jog_feedrate 6000 # y jogging feedrate in mm/min

panel.gamma_jog_feedrate 200 # z jogging feedrate in mm/min

panel.hotend_temperature 210 # temp to set hotend when preheat is selected

panel.bed_temperature 60 # temp to set bed when preheat is selected

# Example of a custom menu entry, which will show up in the Custom entry.

# NOTE _ gets converted to space in the menu and commands, | is used to separate multiple commands

custom_menu.power_on.enable true #

custom_menu.power_on.name Power_on #

custom_menu.power_on.command M80 #

custom_menu.power_off.enable true #

custom_menu.power_off.name Power_off #

custom_menu.power_off.command M81 #

# Only needed on a smoothieboard

currentcontrol_module_enable false #

return_error_on_unhandled_gcode false #

# network settings

network.enable false # enable the ethernet network services

network.webserver.enable true # enable the webserver

network.telnet.enable true # enable the telnet server

#network.ip_address auto # use dhcp to get ip address

# uncomment the 3 below to manually setup ip address

network.ip_address 192.168.3.222 # the IP address

network.ip_mask 255.255.255.0 # the ip mask

network.ip_gateway 192.168.3.1 # the gateway address

#network.mac_override xx.xx.xx.xx.xx.xx # override the mac address, only do this if you have a conflict

Having never done a rotary delta I will have to review the details to get an idea of where the problem resides. But perhaps one of the smoothie guru’s like @Arthur_Wolf would be a better starting point.

Thanks Eric hopefully Arthur_Wolf will notice the post shortly

I’d appreciate a video of the homing.

Also, can you try adding to your config:

delta_halt_on_error false

Also, try setting the W parameter to 1 (M665 W1 I think) and try running the homing again?

Looking at the code, it looks like you’re trying (through config or movement) to ask the machine to do something that’s mathematically impossible.

Your input is very much appreciated Arthur, I will try and make a short video tomorrow.

with regard to the line you’ve highlighted in the file, I have seen this in the eeprom somewhere so I will go through it tomorrow and post again.

Thanks to you Arthur homing is successful!! , as I hope the vids show. There is still a problem I have to overcome and that is when the arms are below the horizontal homing stops when the arms reach horizontal and it shows “homing cycle failed- check the max_travel settings” but whatever I try makes no difference. but if I raise the arms to just 1 or 2 degrees above horizontal homing works as it should (I think) problem, the vids are larger than this program will allow .

The option I added prevents it from complaining, but it’s complaining for a good reason you need to figure out based on the math.

For the video, try youtube.

It was complaining for a very good reason Arthur, and as usual the problem was right in front of me-- I had entered the wrong dimention for the Delta_Z_Offset . There is still a lot of tweeking to do but it is now basically working as it should. I managed to upload a video of it homing at the end of a “print” ( I have yet to install extruder and hot end) The video is on Vimeo I think you can find it seaching for Rotary Delta 3D Printer

So glad you got this to work, I added the video to the gallery on the wiki.

Thank you Arthur, but lets not forget that if it was not for your input I would still be scratching my head wondering what to do next !!

If you want to thank me, once the machine is printing, make a video showing it’s printing, publish it to youtube, and give me the link so I can share it with the Smoothie community