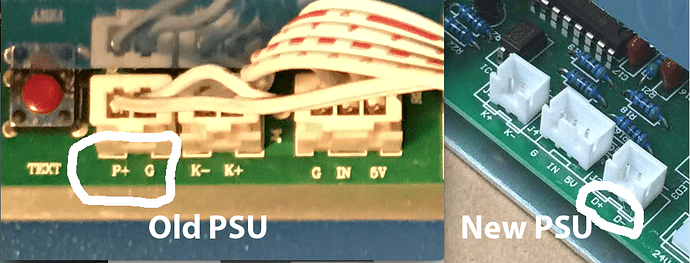

On your OLD Power Supply:

The P+ and G are your Laser enable switch (“LASER SWITCH” on the K40 panel)

K- and K+ are the “LASER TEST” switch and “G, IN, 5V” is the Power setting pot on a K40 (In takes 0-5volt signal to set power %.)

Pin #4 of the power supply connector is the “Fire” signal (5v pulse)

So…

On your NEW Power Supply:

The new supply has the 1st connectors (Laser enable and level pot), so you’re all good there,

I can’t see the power connector on the new supply, but if it matches the old one, it should be pinned as follows:

1 - 24V, 2 - Gnd, 3 - 5V, 4 - Fire signal.

Check your new supply and confirm that matches.

All else being equal, all that’s left, is the D+ and D- lines. which I’d have to bet, if I were a betting sort, that they are indeed the Laser Enable loop.

The Laser Enable loop often has more than just a enable button in the circuit, it also is the place where door interlocks, water flow switch and that sort of thing go. ALL must be closed for the Laser Fire signal to actually fire the laser.

So, connect the wires from P+ & G to D+ & D-, and she should be all good. Polarity doesn’t matter, despite the designations.

This assumes the fire command is indeed pin 4 of the new power supply’s power out connector and the 24v, Ground and 5V pins match as well. That’s critical.

1 -24v 2 - Gnd 3 - 5v 4 - Fire

Good luck!

Scott

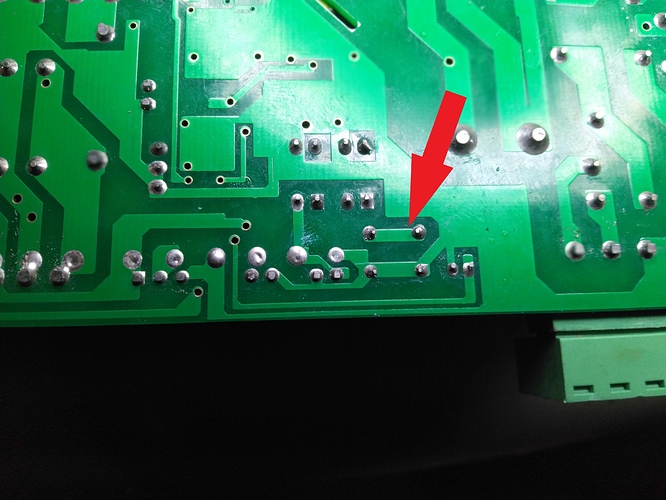

I want to know what the electronics behind the control inputs to the supply are, I suspect they are optical isolators.

I want to know what the electronics behind the control inputs to the supply are, I suspect they are optical isolators.