Hi every one,

Another update,

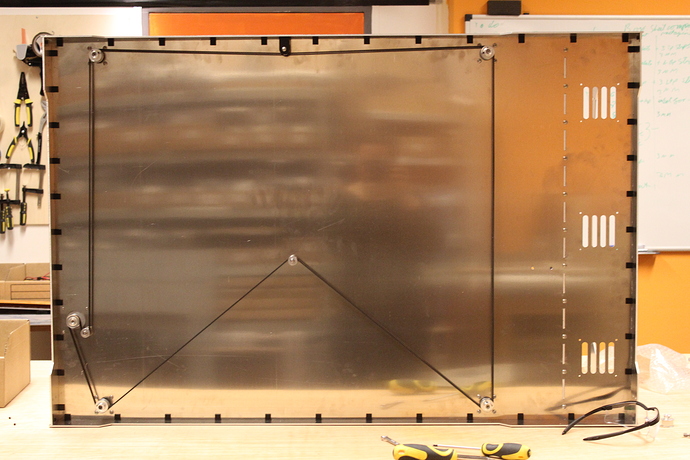

The FabKit Mk4 is together! Good news, nothing major was missing and it looks great! Sadly the logo no longer lights up, but I think having better air flow wins!

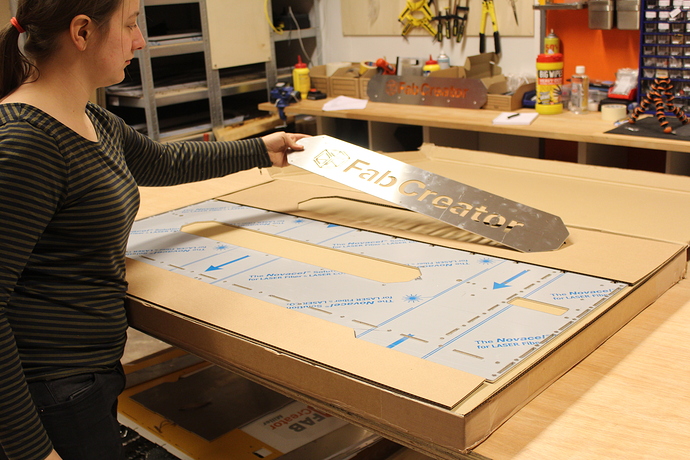

We tested out our packing and pretended to be you when putting it together, so we think we have a fairly good idea going forward with the manual.

The manual is taking a little longer to do, we wanted to make sure it is clear so you don’t find yourself having to take it apart because you missed a step or we did not explain it well enough.

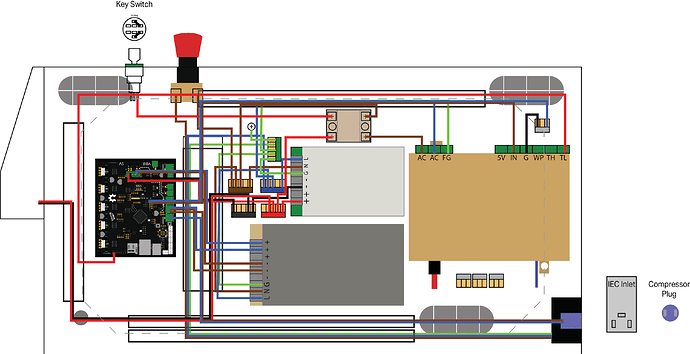

We are also waiting on a few parts that we added to the electronics such as more wago connectors (they make life so easy), and a bag of nuts which we ordered in the wrong pitch. Other than that everything went together without any issues.

So what is on our to do list?

- A few corrections to some of the sub assembly bags discovered in our test assembly (Some extra screws here and there).

- Packaging of the sheet components box

- Packaging of the hardware box

- Cutting and crimping cables now that we have finalised lengths.

- Packaging the electronics box

- Writing the manual.

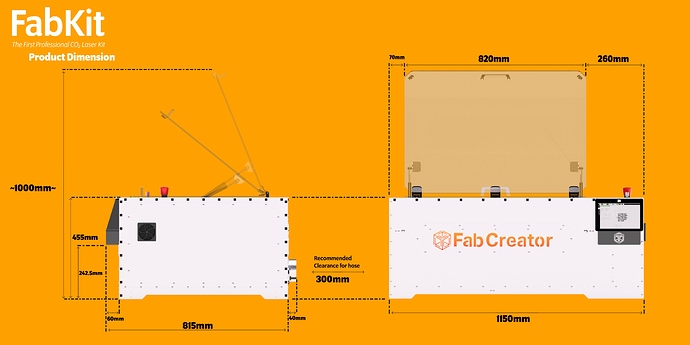

In the images there are also dimensions of the Fabkit to help with your preparation of its location. The extraction hose from the machine can come from the left or the back, you will ideally need an extra 30cm for the hose.

(we recommend the back for best air flow)

The fans we use have an air flow of 520m3/h.

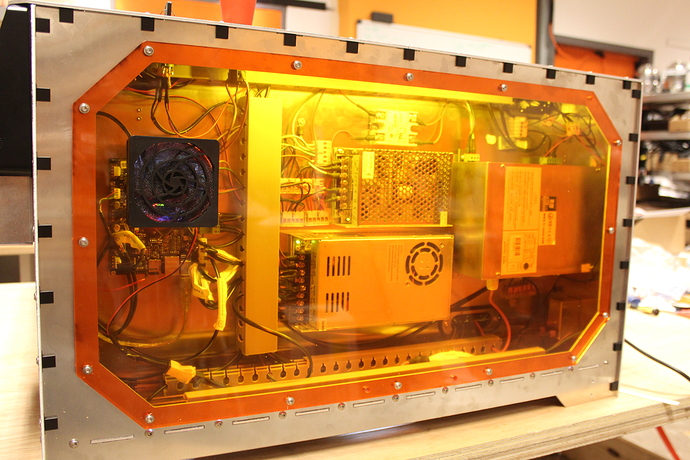

Although acrylic in the images, your electronics panels will be metal

We also did some quick tests with the decibel meter. The machine operates under 50 decibels, with the compressor running, it is around 60 decibels.

Will try and post a draft of the manual later this week so you can get a preview,

I know some of you are getting antsy but we are working as hard and as fast a possible without cutting corners.

Thanks again for your support and patients.

great job!

great job!

ask away it normally means we have forgot something

ask away it normally means we have forgot something