please do critique. I’m mostly stuck just waiting 2-3 weeks for parts in the mail that I ordered a few days ago. If anyone would like the files let me know and I’ll send you a copy.

What parts did you need to buy?

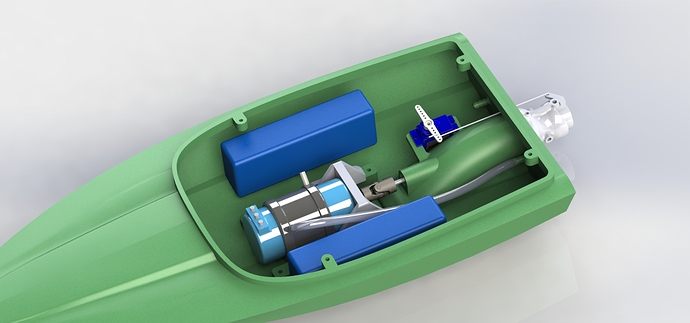

Just the motor and ESC. https://m.aliexpress.com/item/32746000103.html

I have all the other bits already.

It’s pretty overkill. Might downsize later I’ll see…

So this is essentially ready to go?

If so can you send me the files? I’ll print and give it a shot and critique for improvement for sure.

Pretty much ready to go! How can I best send files? I’m new to the Google+ platform

EDIT: will post link, uploading to youmagine atm.

@Will_Nelson What are your motor dimensions? I can design a bracket to suit your motor if you’d like.

I have a few more to choose from. Let me print it out and see what one is best.

Any recommended print settings, i.e. perimeters, infill, etc.

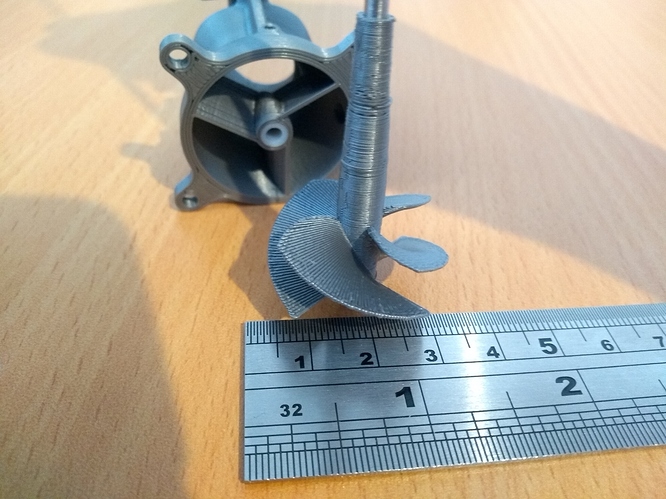

25% infill works well. 2 or 3 perimeters. It prints best upright and cut into a 2 or 3 pieces with supports enabled. Let me know how it goes  I’d do it in PLA and super glue the parts together. 0.2mm layers or so.

I’d do it in PLA and super glue the parts together. 0.2mm layers or so.

I still need to remodel the cover that goes on top of the boat. I’ll let you know when I get that added to the link above.

Does anyone know if a thrust bearing be required? I what I mean is, a collet that sits on the shaft, takes the force and transfers it to a thrust bearing rather than the motor taking it. I plan on using a universal joint atm so just wondering if it’ll be required to give it a reasonable time span. @Will_Nelson I’ve made a bunch of small changes in a few places I can post those soon too. How’s your printing going?

@Jotham_B

Haven’t started yet. Will probably start tomorrow. Had a couple things in queue.

As far as using a thrust bearing, the commercial boats I have all have the flex shaft connected directly to the motor.

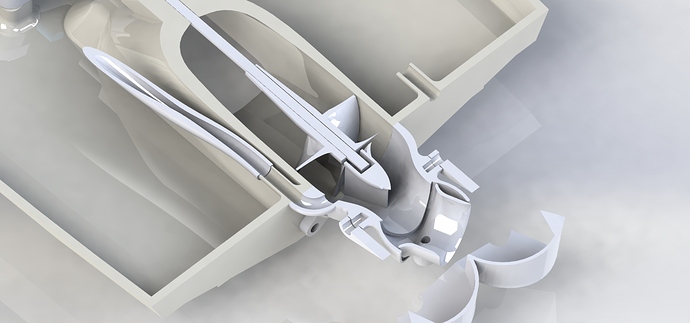

Thanks for the info regarding the thrust bearing. Cool well I’ll update all the files now. Yesterday I probably spent about 12 hours in CAD just perfecting the intake shape, add a better servo mount, redoing the cooling tube connection to be a barbed one, new impeller (has a lower pitch and now has 4 blades rather than 3 with a nice curve leading edge). Tweaked the motor mount to have slots instead of screw holes to allow for more versatile mounting. And I think thats about it. Somehow its surprisingly time consuming but thats alright, I enjoy it  Cool I’ll chuck up the new files now.

Cool I’ll chuck up the new files now.

Just updated everything. I’ll be printing it tomorrow! I’m excited to see how this turns out after spending so much time working on it, it looks good even if I say so myself haha  Btw I’ve included a copy of the hull.stl as hull_cut.stl which has it in 2 pieces to accomodate for your 240mm Z height printer. I’m looking forward to getting this bad boy running that’s for sure.

Btw I’ve included a copy of the hull.stl as hull_cut.stl which has it in 2 pieces to accomodate for your 240mm Z height printer. I’m looking forward to getting this bad boy running that’s for sure.

Mmm. Ive got loads of PLA spools, but only one PETG, ABS and TPU spool each. I’ll go with PLA for now, the blades are rather thin so they may shear off at extreme load or when coming into contact with water again after getting some air perhaps. The good thing is that the impeller and nozzle can easily be changed if required. Handy in case we come up with some improvements or want to do efficiency testing of various designs.

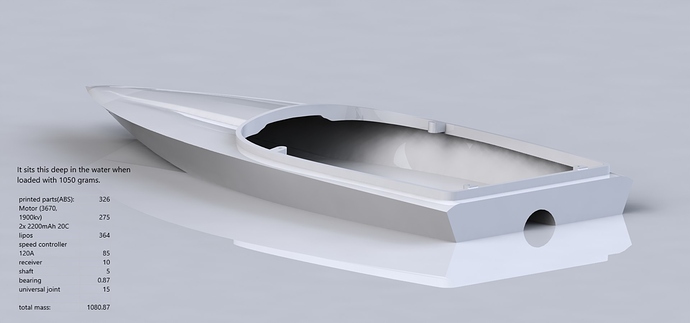

Waterline calculations: (I did the math when I rescaled it. Previously the old 390mm long version would have sat only 1cm above the waterline).

Currently it’d sit as deep as pictured and it’d only sink 7mm deeper if you added 330grams more. The early prototype sat about 1cm above the water line, it almost sank with a 140g motor onboard and the two 2200mAh lipos.

Just found a great thread on 3D printing jetpumps. This looks like the most useful resource by far!

https://www.rcgroups.com/forums/showthread.php?2689573-Home-built-jet-drive-boat-3D-printed

EDIT: Also whole subforum dedicated to jetboats: https://www.rcgroups.com/jet-drive-boats-1004/

A thread completely dedicated to 3D printable jet pump units: https://www.rcgroups.com/forums/showthread.php?2826297-3D-Printable-Jet-Drive-project

Wow!

There you go. Im am sure someone has solved the mystery in there. Lots of good info for sure. Some of the videos have these things flying.

@Will_Nelson yep. Making some more changes… again! LOL. Just streamlining the intake a little more, then making the nozzle narrow down a little more smoothly. Lots of talk about impeller design so a new one of those coming up. It sounds like I want 20k rpm for a 28mm jet so 1900kv on 11.1v is about right (21.1k rpm and of course, it slows a little). So phew, got the right motor haha. Can’t quiet remember the details atm but in summary, the motor I got is a little large for the pump in here, and the pump is a little large for the hull. ie, 28mm recommended, we have 30mm. 3650 to 3670 recommended for 450-550mm hull and we have 430mm long. Should be good. Its weird, all the RC’ers mustn’t be posting much on the likes of youmagine or thingiverse. Not a lot of cross over going on between the spaces there from what I can tell.