Here’s a rough idea of what I’m planning for a project; I hope nobody minds me thinking out aloud here and if anyone has any feedback or criticisms, please pipe up.

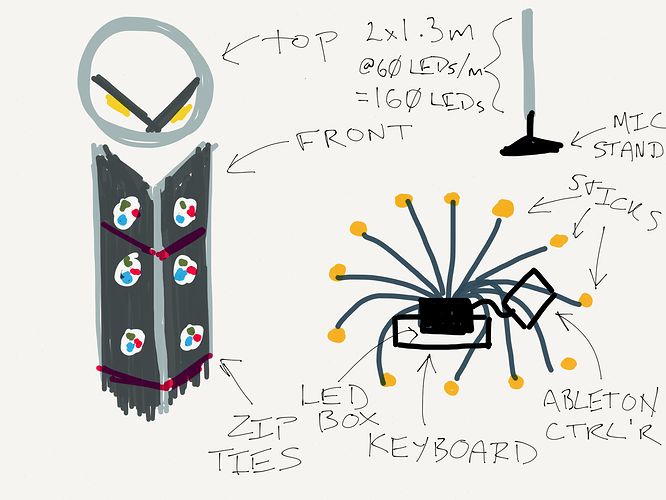

The setup consists of somewhere from 12 to 16 “sticks” mounted on mic stands, placed in a circle around the performer (whose setup is a keyboard and an Ableton controller plus a laptop.) They’ll be a bit lower around the front so you can see his face and a bit higher at the back so he’s kind of “encircled”.

Each stick is 1.3m long, consisting of a perspex tube with a piece of right-angle aluminium channel up the middle. There’s 80 LEDs worth of 60 LEDs/m strip up each outside face of the channel, stuck with the standard adhesive and zip-tied through holes drilled in the centre of the channel.

That means 160 LEDs (9.6A @ 5V) each stick. Somewhere between 576W and 768W total depending on whether we go for 12 or 16 sticks.

For simplicity, I’m thinking to put the PSUs (4 x 200W) and the controller (Teensy 3.1) in the one box, under the keyboard, with one cable going from the box to each stick.This way it can be plugged into the mains in one place and it’s easy to tie all the grounds together, plus I can run the signal for each stick from a different output pin on the Teensy and not have to worry about a signal cable snaking all the way around the circle.

Using WS2812Bs, 160*30µs = 0.0048s per frame in parallel, which is an upper bound on my frame rate of 1/0.0048s or a bit over 200fps. Which I think is plenty. I don’t plan on doing anything particularly computationally intensive pattern-wise? But MIDI (see later) might eat some CPU.

If I’m using a 3 wire chipset like the WS2812B I can use 3 conductor XLR cable to wire everything together: 8 male-to-male cables cut in half will make 16 “tails” terminating each tube; normal M-F 2m XLR cables from there to 16 x XLR sockets on the power/control box. XLR cables have the advantages of being relatively cheap, readily available, stage-proof and, if I make sure to get at least 16 gauge or better, rated for the 10A I want to put through them without dropping too much voltage.

The ultimate plan is to have patterns triggered via MIDI over USB from Ableton (I see there’s a MIDI library for the Teensy), but I’d be happy enough to have manual pattern selection and sound reactivity via line-in for a beta.

Can anyone see anything grossly wrong with this plan? Am I out an order of magnitude with any of the calculations? Am I planning on doing something that will obviously cause me to burn a stage down?

I don’t know if the midi uses interrupts. I think you could even set the Serial input to the midi baudrate (so you have a buffer I think). You could also use OSC or ArtNet (with ethernet) however that might be more processor intensive. I think you would like to run the patterns and effects on the Teensy itself or not?

I don’t know if the midi uses interrupts. I think you could even set the Serial input to the midi baudrate (so you have a buffer I think). You could also use OSC or ArtNet (with ethernet) however that might be more processor intensive. I think you would like to run the patterns and effects on the Teensy itself or not?