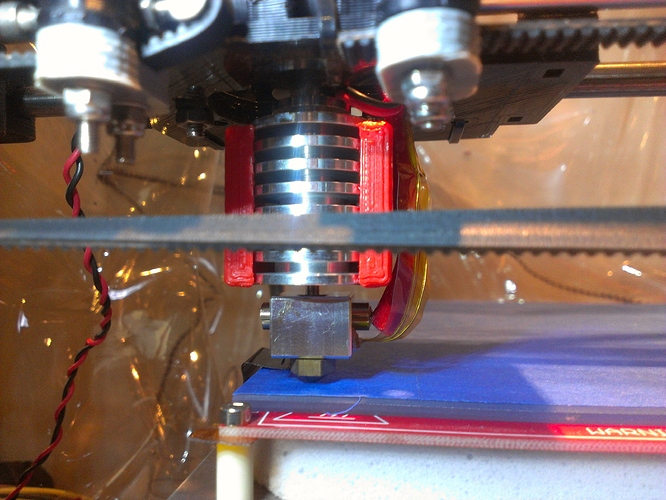

Got my E3Dv4 installed funny how much it looks like my buddhaschnoz setup

Works great, far less drool than buddha. I went from 6 to 3mm retracts with abs. no blobs on perimeter starts.

The fittings were given to me, they are:

Very expensive but they work great.

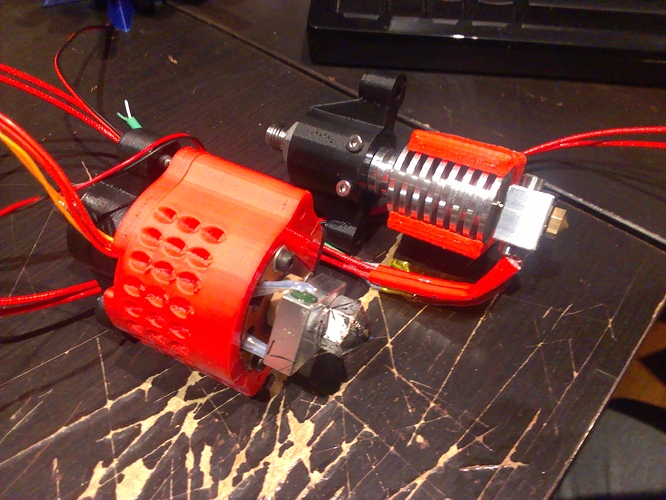

The shroud I designed in freecad with python. I wanted the outgoing air going away from the print. I was sure this thing would melt, but it has run for 100s of hours @ around 240c.

This hotend is great, thanks for bringing it to us. Very interested in smaller nozzles in the future.

So far these couplers have worked really well. Sometimes filament will catch a bit while loading but never had any issues while printing.

I quickly made the printed fitting with openSCAD to mate with the male NPT fitting and a J-head.

@Sanjay_Mortimer : +1 for the thick and thin nozzles. Doesn’t really matter if you sell them as kit or single to me. I would love to buy them anyways.

Sadly I didn’t see that your hotend wasn’t suitable for bowden right away. I’m not sure… would it be an option that I send my (unused) hotend back and wait for the bowden version? Or @scott_maher tells me how he did it. I don’t completely get how you modded it - was there any drilling, threading, CNCing involved?

@Sanjay_Mortimer true! Need to find a good machinist in Bayreuth anyways. I didn’t waste a thought about it before ordering because I’m so used to bowden-ready setups with my Delta and Ultimaker.

Regarding the nozzles: Keep us posted

That’s a nice cooling arrangement for the Budaschnozzle, is that publicly available or a private creation?

in my country, they charge you USD10 to bent anything less than 5 inches wide …

@Jon_Caywood @Florian_Horsch_flouS I’m happy to share, but it’s not likely to fit most setups, as I built my Prusa with an upside-down X axis. I’ll try to post details about my setup with STL’s and source(if it still works) in the next day or so. It’s nothing too fancy. It’s really just a matter of finding suitable parts(PTFE tube, and some kind of fitting) then making some very simple parts to mate with the carriage and hotend you are using.