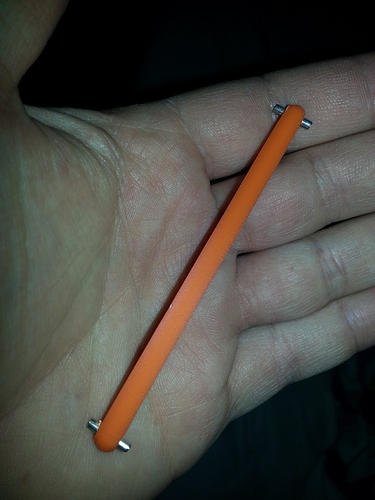

Printed driveshafts…

Oh god, these won’t last. The last time i had to use plastic (injection-molded) driveshafts was on a LRP S18 BX and they all twisted and broke after two runs.

Plastic shafts might hold up to plain old Mabuchi motors, but will inevitably fail with something more beefy.

@Thomas_Sanladerer I was waiting for someone to make that comment!

And i agree of course, but one of the goals i have with this project is to see how far i can take the “printable car” concept. And printing the driveshafts is one step in that direction.

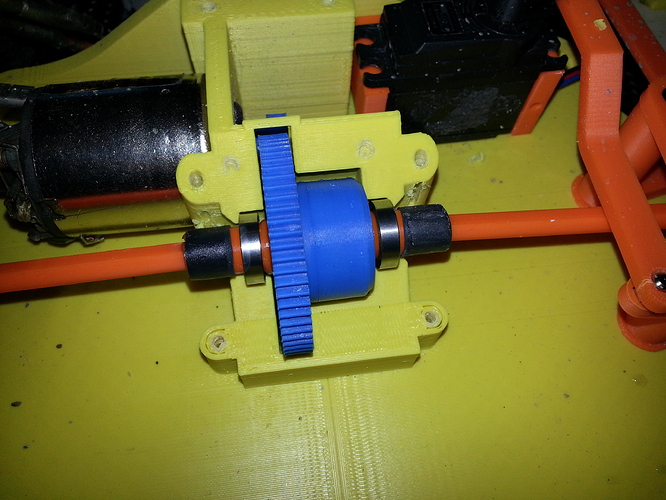

It´s also important to mention that another goal is that i want it to be possible to switch parts like these that take alot of “beating” to “real” parts in a better suitable material. As for the time being i´m stuck with a motor that is basically a relic and maybe a bit slow but still, it works really well with the printed parts.

It´s up to the user to put whatever parts they want in the car, just like @Bill_Ide did.

I’m pretty sure that we could design them in a way so they would last - just like about any part of the car. Make it beefier and, for the driveshafts, use a larger diameter. If the plastic shafts are properly sized, they’ll probably even end up lighter yet just as strong as regular steel shafts.

I agree that it can be made strong enough, but i think it will take redesigning more than just the shaft. Because even if you beef up the shaft you’re going to run into trouble at either end where it connects to the differential or wheel, unless you increase the diameter of those parts as well.

What about printing hollow and poor in epoxy!