Greetings!

The instructions with my Vigo Tec BX20 L7 laser engraver says the recommended distance from the laser head to the work surface is 5cm to 10cm. (1.968 inches to 3.937 inches) Is that possibly a misprint?

The legs on the base of the machine are only about 28.575 MM (abt. 1 1/8")

I do not understand why the base is so small if they recommend raising the machine

nearly 2 to 4 inches from the work surface.

Thanks for any help and helpful suggestions.

God Bless! Bob

The videos that I watched with these machines seem to print at the depth of the side frames?

Have you tried engraving at that depth?

You should be able to find the focal point by doing a ramp test.

In this test, you etch a line on a material that is sitting at an angle under the head’s path.

As the laser moves across the material it’s marking FL will change.

Procedure:

- Put the gantry on blocks that position it above the expected focal length.

- Put a piece of material ramped under the heads i.e. Laying at an angle. Ensure the ramped material crosses the plane of the expected FL

- Etch a line the length of the ramped material.

- Look for the thinnest area on the etched line and the distance from there to the head is the correct focal length.

Thank you very much, Don!

Your suggestion just may give me a better idea of what will work best for me.

Originally I did try engraving with the engraver just sitting on the base provided and

was getting decent results but, the engravings were really erratic. For example, a test

engraving on scrap material from the same work piece I was using would be great but, then the actual engraving on what I wanted to be the good project would get wavy or skewed.

I wondered if I was getting fumes, smoke, or heat causing the inconsistency.

Recently I put the engraver up on blocks, readjusted the finest point I could get with the diode head and, even though the work piece was now about 2 inches from the head I could still get fine detail. Unfortunately, I still get the same problem with inconsistency from one engraving to the next.

Your ramp test probably won’t solve the problem with inconsistency but, at least it should give me a good starting point to keep the laser head the same distance from the work piece regardless of what thickness of wood I want to engrave on. From there, I can measure things up and build an adjustable base to raise and lower the entire machine when I change wood thickness.

Sorry this got so long winded but, I really appreciate your time and effort to help me out.

God Bless! Bob

Engraving can be picky especially if you are running marginal power.

There can be inconsistency within materials and from two samples of the same materials.

I would try the following:

- Test with various speed and power settings

- Put a fan nearby to blow the fumes away or put a small fan on the gantry

- Test with various materials

Post a picture of good and bad engravings to give us more perspective

Wow ! what a simple and effective way to find the perfect focal length ! Thank you for the insight Don !

I find that certain woods have soft and hard areas. Especially Pine, When the laser enters a soft area it burns too much. I think that if you look at the cross grain and pick a piece that has even horizontal lines that are tightly stacked you would get a more even burn. What think you group ?

Yup and the moisture content of the material makes a big difference.

For the benefit of others, what was the correct focal length

I ended up raising mine to about 7 cm. Working much better.

Thank you all very much for replying to my question,

I presently have mine set at about 5cm but, really don’t see much difference in

the quality of the engraving as long as I adjust the focus well.

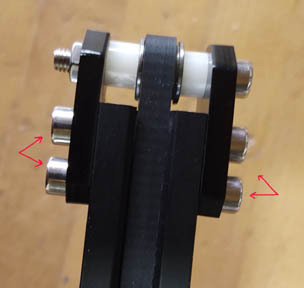

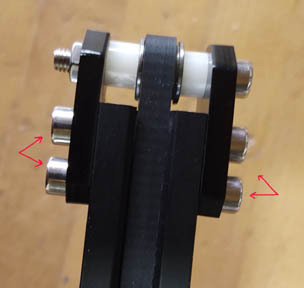

I think part of my problem is the belt may be slipping on my gantry.

What is the proper way to adjust the belts? I have enclosed a photo showing with red arrows 4 bolts that I think may give me some adjustment if I loosen them and pull the fixture outward to tighten and a photo showing how the text was skewed while burning.

Another question is, when the need arises, does anyone know where I can obtain new belts for the laser engraver? The original seller was not helpful at all so I cannot go to them for any type of support or accessories.

I’d sure like to get some consistent engravings with this after investing the cash! LOL

Thanks very much for your continued help and guidance. God Bless! Bob

I do not see the pictures.

I can see them, maybe refresh the page?

Did that help? Thank you

I see them now.