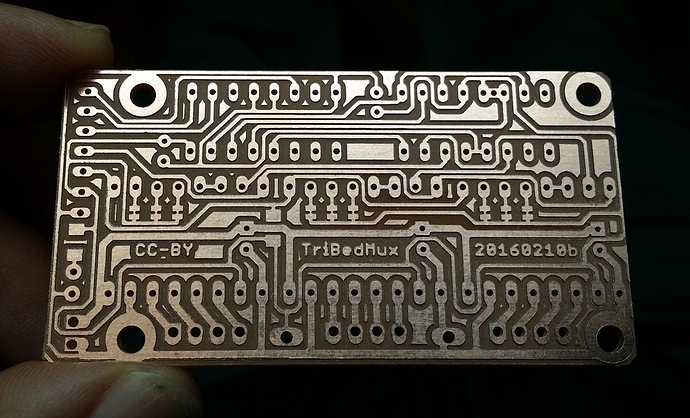

First time I really need to mill a dual sided PCB (with eagle + autolevel + pcbgcode)…

While looking at others’ jobs, I realize many people are drilling the holes before milling the paths, which makes sense (smaller risk to tear the taces apart?). But I fear that the Autolevel tool will fall on holes while probing.

Also, I did not find an option to drill holes with a single milling bit, which would be nice to spare the time I spend changing drill bits and approximating the many different diameters.

FInally, some people spray liquid on the board while milling. Is this really useful?

Do you have any advice? What’s your workflow when milling dual-sided PCBs?

@oscar_riojas but it’s only a single side… I will post if/when I eventually make a double sided one, and I should write about it just for my records! Meanwhile, I just crashed the drive for linuxcnc on the old computer, huh (I always wished I spent the time and switch to a smoothieboard and a modern PC for example… the parallel port requirements makes life hellish)

Note to myself: make sure to keep in mind that the vias are NOT connected once milled, even if it looks like chemically-made PCBs…

I spend hours staring at my own schematics and eagle board layout while not getting it why I did not get all my signals!

I bought some rivets but I do not have the appropriate diameters of course (see, e.g. http://www.oz4.us/2015/11/count-items-you-receives-from-ebay.html )

@oscar_riojas actually I soldered thin single-core strands both side, that I cut almost flush, but I forgot a few ones at first. Filling would be neater, and using solder paste is a good indea indeed (I would have to block the bottom side of the hole – unless capillarity does the job). Next time I try