So, I am having a minor problem when I try to print very large items with PLA+ although normal.PLA is ok. I will not even mention PETG . I find some lifting of a corner. And it is always the same corner.

From what I can fathom 8from the interweb, and also my friendly FDM afficaionado it is probably a temperature issue . My current workshop layout is not the best environment at there are serious drafts and the temperature range (as winter approaches) ranges between bloody cold to near absolute zero. But as I know from last summer (so long ago in my memory) the temperature ranges from mere Saharan to solar.

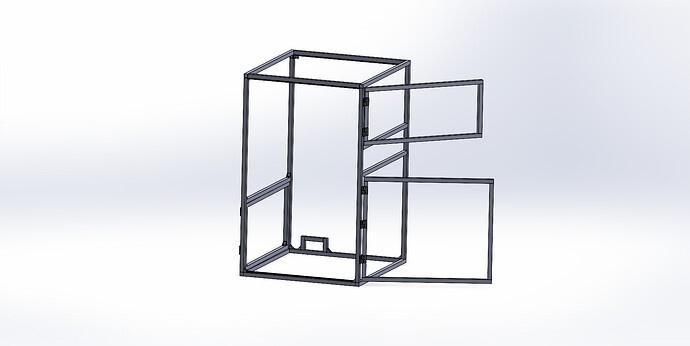

So I have designed an enclosure that includes temperature control (peltier units) and diffused air circulation along with the appropriate temperature control. I have drawn up everything in SOLIDWORKS and STL, and will include a bill of materials, and the wiring diagram (fritzing) and the Arduino code to control it all.

According to my local websites, I should have all the components needed by Christmas. And so, by new year I will have the entire enclosure built.and tested with two or three different filaments. If it all works to plan, I will posit everything here. As it can all be ordered from places that cut aluminium extrusion to length, places that cut perspex to size and the ubiquitous Amazon.

The designs for an X5SA, and includes access to the rear existing filament mount, but also to a top mount for filament when using a direct drive extruder. If you all can give me a couple of weeks trial, I will post everything as either a cut-list, STL or step files so you can edit them as needed.

I will include a list of Arduino components, pinouts and the relevant code as well…

But here is a basic.image to wet your appetite