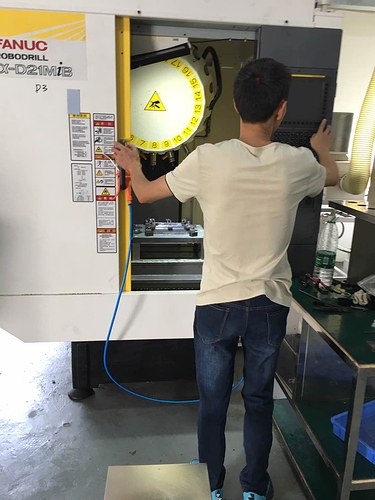

CNC tools debugging and processing.

Please do tell @zora_zeng , what was the bug? Was it tool position number nine? I usually have to take my troubles down to Ms. Ruth on Vine. How did you find it or did it give you some sort of magic sign? I don’t know if it’s day or night where you are, but don’t leave us hanging, how did you solve it? Darn tool position No. 9

@marmil Our engineer just adjusted program command as debug for processing because the tools position was calibration in the CNC machine system before, and it will guarantee accuracy in ±0.01mm. By the way, am confused that who is Ms.Ruth? And you seem profession in CNC, are you special in this industry ?

Oh, Ms. Ruth? She’s got a pad down and Thirty-Fourth and Vine. But that’s not important. @zora_zeng , I’m curious why you posted your photos with almost zero info to a DIY CNC group? As a professional I am still confused what you are trying to share with us?

@marmil Oh maybe there some confuse. I just want to share this picture to show our CNC processing capability, and we will take continuous improvement in milling. Now it is just numerical control machine, but we will import 5-axis NC machining and write more different programs for better production in the future.

@zora_zeng this is the do it yourself CNC group. How long did it take you to build this yourself? What was your budget? Can I make one for $2000US? Where can I get the parts to build my own. Can I plug it into an outlet in my basement on circuit breaker number 9? What will it make to keep my wife happy with the expense?

Big iron is fun to look at but hard to carry down the basement stairs. Do you think you’re in the right G+ group, since effective marketing is right place right time right product?

@Kirk_Yarina Dear sir, maybe there some misunderstand and I will answer your question one by one. First, this CNC processing factory is not belong to me,I just work here. Second, This plant have built in 2007, it has grown up from a small area to a plant in 10 years. Third, it is nice that you want to make a CNC plant by yourself, but the $2000 is not enough because $2000 just afford a machine, but not contain cost of labor, site,etc. Last, I don’t know how much expense will make your wife happy.

By the way, I think I am in a right G+ group, we all devoted much in the CNC machining, we are here for information share and get promotion from others sharing.

Thank you for your question.

@zora_zeng this is do it yourself CNC and you are advertising something that is not appropriate for people to build themselves or use on a hobby machine. Do you not see the problem, dear friend?

Yes, other vendors are not doing their homework and inappropriately posting here. You have no customers here so you are wasting time and annoying people and will not produce any sales. You may lose sales by being a spammer. Good luck finding the right groups to post in; this is the wrong place

@zora_zeng I wish you good luck finding the appropriate place to post. I also do not know the maximum expense that will keep my wife happy, she keeps that a secret, but it is much less than a big factory