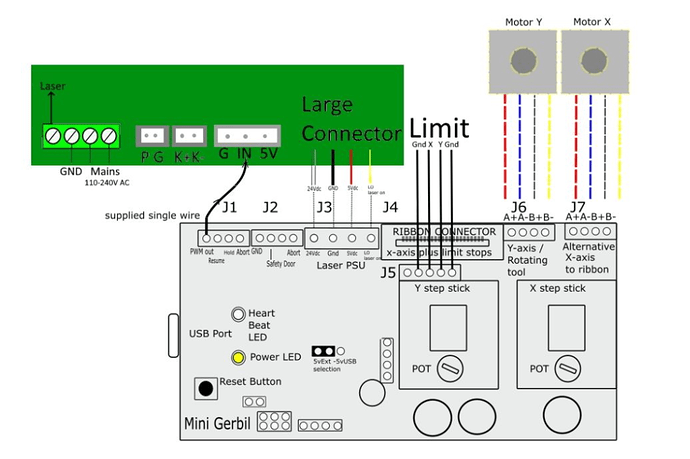

Is there a way to do the usual thing where power is set with a 20+ kHz PWM signal on IN and the laser is fired by pulling L to ground?

Bonus question: Is there a way to add pause (feed hold) and resume (cycle start) buttons?

In case anyone cares, here are the reasons why I’m not interested in the L-only PWM hack:

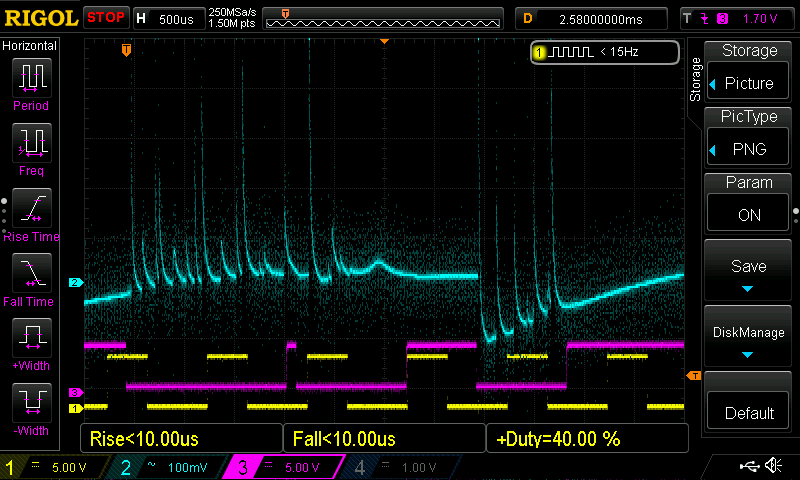

Setting IN to a fixed voltage and PWM on L does not look like it’s the way to do it. Controllers which support RF and DC tubes (e.g. Ruida RDC6442 G/S) use one pin for RF tubes and two pins for DC tubes. Why would they bother with another pin and a few extra components if this would be completely unnecessary? As far as I can tell, no controller you can find in Chinese or “Western” machines uses only one pin.

That one L PWM frequency works better for cutting and another works better for engraving also suggests that this isn’t quite right. You either lose power or fine-grained control. You don’t have this problem with two pins.

The wiring diagrams and pinouts from the power supply manufacturers also tell you how these two pins are supposed to be used. An L-only alternative isn’t mentioned anywhere. (Please correct me if I’m wrong.)

There doesn’t seem to be any advantage in using this L-only PWM hack. It seems to kind-of work, but not as good as using two pins. It isn’t equivalent or better. Therefore, I have no interest in using it.