From the one-string stepper motor youtube video above, in the comments:

I was able to pause 75 microseconds between each half of the cycle. Below 75 microseconds, the result was unpredictable. There were 485 steps from E to F# with each step taking X time plus the 150 microsecond delay. I don’t have a way to quantify the amount of time (X) that the motor needs to actually do the move but the total time for the move is slightly more than 72,750 microseconds or 72.75 milliseconds. Another way to say it is slightly less than a 10th of a second.

Pretty close, I guess. That was a pretty hefty stepper motor though. Would a smaller one be slower? Or just less powerful? 70 ms. is pretty close to my target. That much latency on a key press would be murder (I know because I used to play organ at hockey games!) but I’m assuming this figure is not exactly comparable to latency…

I’m not entirely clear on how dc motor controllers work. Can you explain from an electrical feedback perspective what difference (if any) there is between a stepper motor and a speed controlled, geared-down DC motor? I feel like the motor is going to be more ‘analog’ in its response, but that may be a mis-perception. In the explanation above, the motor has to move a step, wait, move another step, wait, etc. It has to hit every step between x and y. Would a dc motor controller be able to operate more efficiently? Can it respond more analogly to a rate of change, by simply changing RPM? Or is it more complicated than that?

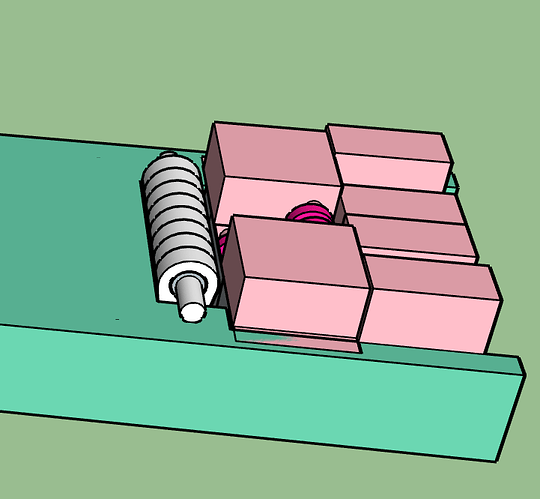

If I have a 1mm pitch, that’s going to cut my response time in half, right? Requiring the motor to be twice as fast… so probably 2mm is right. If I can’t make my own nuts, I figured I would have to file or cut off the sides of the nuts.

This seems to be the only T5 lead screw available on amazon:

https://www.amazon.com/ReliaBot-100mm-Tr5x2-Printer-Machine/dp/B081VN8QRM/ref=sr_1_1

Here’s a tap:

I could probably trim that nut to 8mm, and still keep 2 out of the 3 mounting holes. But I thought if I could make my own threaded holes in delrin, I could keep wear issues down by making the nut very thick, say 15mm or more. And by making the outside square, I could keep it from rotating, another issue I have to address.

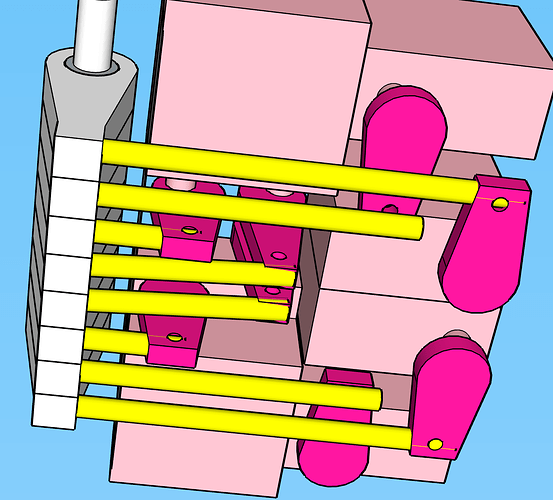

Wow, those bearings ARE cheap! And TINY!! How would I install them in a brass changer finger? Just drill a 7mm hole and pound them in? I think I’ll need at least a T5 axle and maybe thicker, to avoid deflection in the center, unless I build a fancy ‘cradle’ for it. I’ll see what’s available a little bigger. Axles on steels are typically 3/8, but some folks seem to get by with 5/16. I guess it depends a lot on what the axle is made of, as well. So yeah, if I have a tough axle, I could use these:

uxcell MR128-2RS Deep Groove Ball Bearings 8mm Inner Dia 12mm OD 3.5mm Bore Double Sealed Chrome Steel Z2 10pcs

(the actual link shows the wrong size…)

Yes, I have over 8mm of width to work with. A lot of steels are 5/16… the multi-kord is 3/8! But my lap steel is in between, and I like the spacing. T5 seems about as large as I could go for a lead screw. Most of the motors I’m looking at have M4. And although they say ‘lead screw’ nobody mentions the pitch, or whether they are trapezoidal. It looks like they have 1mm pitch, to me.

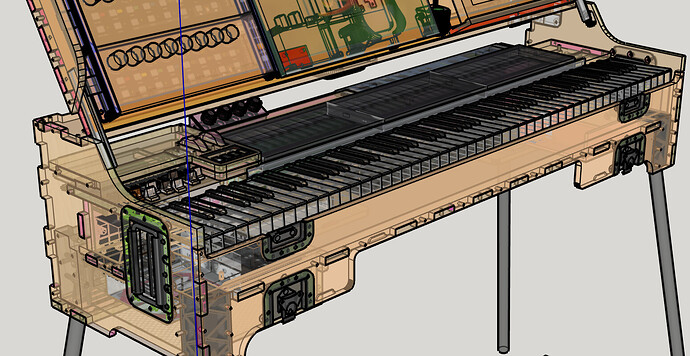

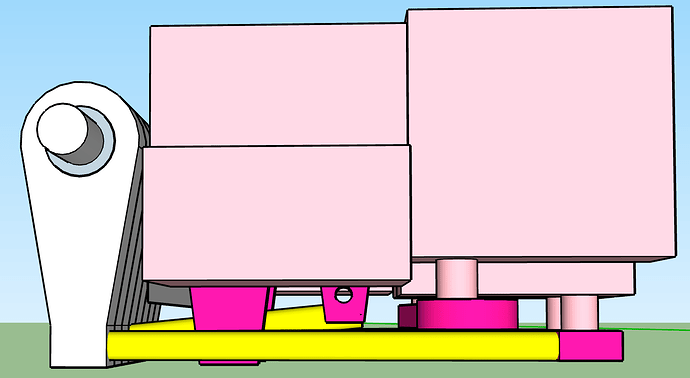

I came up with an idea for a layout where the geometry is such that I’m moving the lever up and down, and had some motors facing upwards and others down. That buys me 17mm of width. Enough for 8 of these:

https://www.amazon.com/gp/product/B07HJYXB4S/ref=ewc_pr_img_2

Two up-down racks would give me 34mm, enough for a larger motor, and perhaps with different geometry I could make both racks respond similarly. Still sketchuping on that one… I’ll post something when I get it figured out.

It’s a good point about the cables. Plus they would be very short cables. I’m still worried about stretch or play giving unpredictable results. You wouldn’t want to use them for both pushing and pulling would you? So you wouldn’t want to counter-balance your string TOO accurately. I will say that folks on the steel forum have suggested this is not a real concern, as springs respond differently than strings. So maybe just pulling, with some resistance coming from the lever, is best in that situation. And they will be under far less tension than the ones on the Multi-kord. So yeah, I’ll think on that.