Brandon

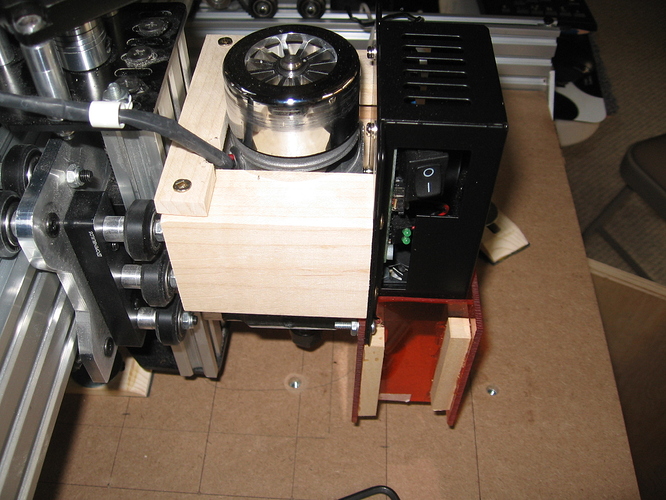

I would like to order the dust boot but I need just a little info. I’m attaching a picture of a 2.8w Jtech laser hooked to my 400 w spindle on the Ox. My set up has the laser and driver mounted to a plate that was used on my Zen toolworks machine. Looking at it will it fit on your boot as you said it is set up for a Jtech laser. Please don’t laugh at the set up as I was just trying to mount something quick to get the laser to work. It is riding on the upper spindle clamp.I have it working so I’m ready to use a different mount. I don’t want to separate the laser from the driver on the plate. Anyway I have the system working with pic sender and pic laser if anyone wants the $Gcode setup.

Now that’s pretty innovative. I wasn’t sure how to set up the laser on the Ox spindle.

Bonust points for building something period! And, points for actually shielding it! Fail early, fail often, and make progress! My usual method it to 3D print draft parts and test fit. I’m close on my install, but I am leaving the power supply on the non-moving parts; I ran cable through cable chains.

I was serious. I purchased a mini laser months ago, but couldn’t figure a good way to mount it

Morning @Dale_Maxim it looks to be the same, but we do mount the PSU for the laser off-site.

Like the mount!

I’ll consider separating the power supply from the laser when I take it off. It would decrease the weight but with the small spindle and reinforced carriage I think I’m all right. Anyway I’ll think about it. As far as the cable chain mine is stuffed already and it wasn’t worth it to me to try and do that again. I ended up with 2 cable chains on the Y axis. The bandsaw looks interesting. My rube goldbergs don’t get painted. You are adding a touch of class to yours.