Although it wasn’t the main intention of this test, Ares’ Z shortage is all but confirmed.

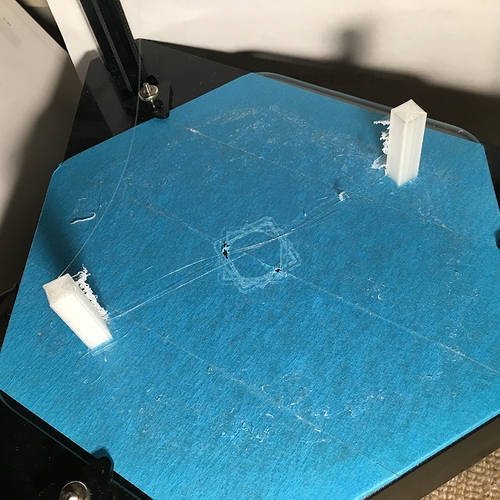

This test comes from multiple inspirations. When my imprecise caliper showed a 0.2mm shortage on a 20mm horizontal edge, which was also the first discussion in this album, several people suggested larger print. Richard suggested an easier method, by printing two separate cubes at the ends of printable range. But I really couldn’t manage 123 Design or MeshMixer to even make proper twin cubes. The maximum separation I managed was 30mm! (4th picture) I knew that CraftWare had an easier graphic interface to place objects but I couldn’t make it work with Ares. Till Michael’s CraftWare profile for Ares helped me out. (Sign in - Google Accounts)

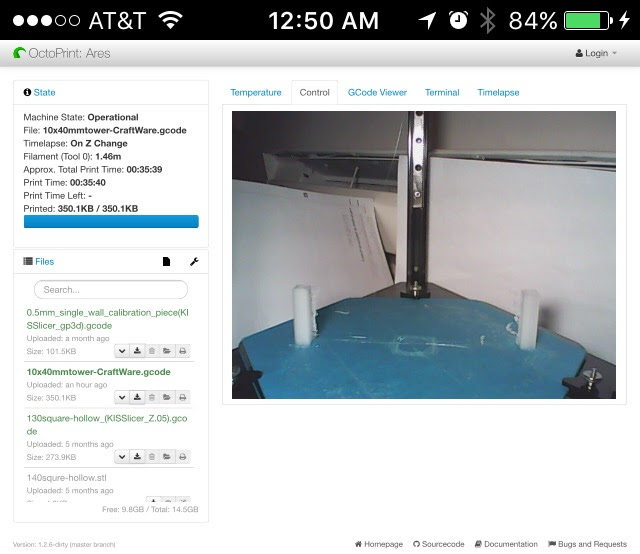

Tonight I used CraftWare to horizontally separate two of 10mm x 10mm x 40mm tower from the MakerBot calibration kit (http://www.thingiverse.com/thing:2064/) by 150mm so their outer edges are 160mm apart, Ares’ printable diameter being 180mm. In doing so, I also raised draw speed to 70mm/s because I wanted to test out speed. Additionally, as the entire temperature tests show excellent temperature tolerance in GP3D filament on Ares, I chose to print at 195ºC. (This is the temperature recommended for Ares’ original filament.)

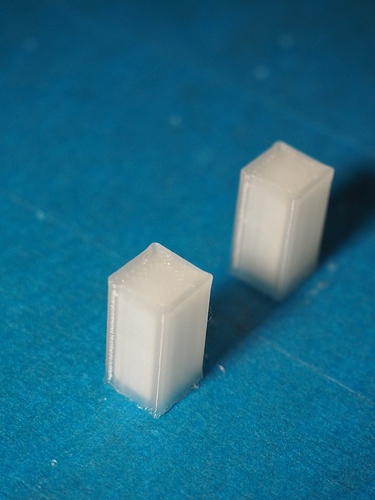

Once again, Ares shows excellent horizontal accuracy. (2nd and 3rd pictures) 70mm/s causes in serious hair and string in travel. Whereas these two are expected, an unplanned aspect is not.

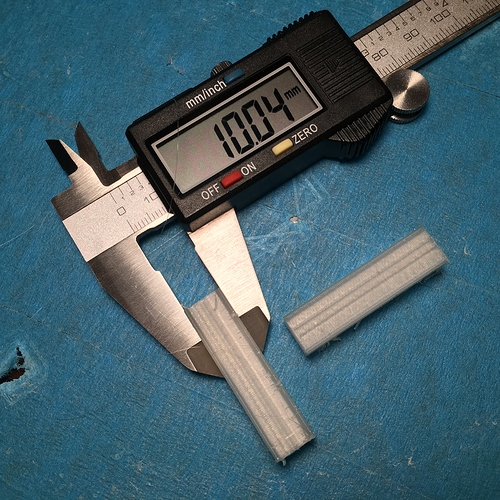

While CraftWare led me to David Cushing’s temperature calibration cuboid, the 100mm height comes ~0.9mm short, raising the question whether Ares has a Z shortage. (Sign in - Google Accounts) So, the 40mm height is an opportunity to test Ares’ vertical accuracy again. The first picture reveals a 0.8mm shortage from 40mm, even more serious than with the 100mm-tall cuboid.

I cannot find any proportional Z parameter in Marlin’s Configuration.