Yesterday I could vector cut 4mm acrylic in 2 passes; today 8 passes don’t cut through. Redid alignment, cleaned all mirrors, and everything seems okay. The other issue that has recently appeared is a grinding sound from the steppers and no movement. Shut the machine down, move the head a few mms by hand and it homes on startup. Open to any and all suggestions.

Post a video of the sound of the steppers?

Unless it’s a failing power supply, I would expect them to be unrelated issues.

Welcome to the forum Rssutton!

Do you have an air assist? When you check the mirror alignments do you get a single spot on the tape or multiple spots from a single pulse? What are you using for cooling?

I second a video of the grinding if possible.

Thanks for the suggestions. I will try to make a recording of the sound of the steppers. I don’t think any of the mirrors are defective or scratched, but will check again. It seems to work okay on vector etch and raster, but I’ll double check and post tomorrow.

Good afternoon,

I now have more data, more questions, and a few proposed solutions.

To answer your questions first, the coolant is distilled water, always flowing and checked with a flow meter. There are no visible air bubbles in the tube as I’ve built my biceps picking up the machine and rotating it. Total time on the laser tube is << one hour. I have all the components to install air assist, but haven’t done it until I overcome these difficulties.

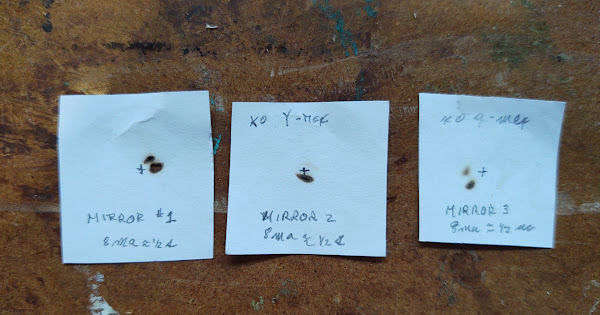

There are two beams coming out of the tube to mirror #1. Here is a link to the test strips from all 3 mirrors with 8ma drive for about 500 msecs. It occurred to me that the beam could be piercing the test paper, hit a defect, and then create the second hole by reflection. To test this, I also pulsed the laser with a piece of veneer. Two dots with nothing on the back side. Two beams are coming from the laser. The other strips are taken with the carriage at the extreme X and -Y positions. Not perfect alignment, but also two beams coming into the third mirror.

I inspected the mirrors closely. At first they seemed clean, but I notice a small smudge on mirror two that doesn’t clean off. Could the reflecting coating be damaged? In any case, I just ordered a new set of mirrors and an 18 mm lens. The K40 is a Barbie Doll for geeks like me; the laser is cheap, but the accessories are infinite.

Here is a video of the grinding noise. I positioned the head about 10 x -6 from origin and then applied power to the laser.

I checked the squareness of the X-Y anodized bronze rails. They are about 2 m.m. out of square over total travel. It doesn’t seem possible to maintain accurate alignment of the beam with this distortion. I could feel no looseness of the rails or means to square them up. It doesn’t sound like a bind that’s creating the noise, but could a misalignment of the rails trigger asynchronous operation with the steppers?

I thinking of taking the drive mechanism out of the case and squaring it. Have you done this or know anyone who has? While it’s out installing the air assist would be easier. In short I’m thinking of a minor rebuild of the system - alignment, mirrors, and air assist. OTOH, I hate to “solve” a problem without truly diagnosing it.

Thoughts?

Stan Sutton

Hi Stan,

Your loss of power is most likely tied to the double beam coming out of the laser tube. You either have a damaged mirror on the tube itself or your tube has shifted to a different TEM mode (TEM01 gives 2 spots). Either one is not repairable and would require a new tube. If this is a new machine I would contact the seller.

TEM explainer:

- The power density across the diameter of a laser output beam is not uniform and is dependent on the laser active medium, its internal dimensions, optical feedback design and the excitation system employed. The transverse cross sectional profile of a laser beam, which shows its power distribution, is called the transverse electromagnetic mode (TEM). The higher number TEMs have a greater spread in intensity which makes it harder to focus into a fine spot.

Tubes can suddenly fail for a number of reasons:

- It was a marginal tube to begin with.

- Running the tube at too high of a temperature (Typically 25C is max recommended).

- Running the tube at a too high of a current (18mA is typically the max with 15mA being the recommended max ).

Your video isn’t playing for me. If the file is too large you may need to upload it somewhere else, like youtube, and link to it.

Let me know if you have any questions.

Good morning Ned,

Thank you for your help and explanation of the tube. I may have caused the problem by not realizing air bubbles could form in the tube. When the lower power happened, I opened the laser cover for the first time and noticed there was a bubble at the output end exposing about 1/3 of the metal cylinder (mirror?). Could that have overheated and damaged the laser? In any case, it’s not ultimately fatal as the main use of the machine is to vector etch and raster etch wooden parts.

Here is a shortened version of the video. I will check to make certain it plays.

Stan

That didn’t seem to work either. Try this youTube url.

Stan

If there is a significant air bubble at the end of the tube it can certainly cause the mirror to over heat and become damaged.

In the video is the head suppose to be homing? Is your home set to the back left? I ask because the sound is still heard even after the x-axis motor has stopped. If this is the case I would suggest checking the y-axis belt tension and any couplers present going to the y-axis motor. (note there is a belt on both sides of the gantry for the y-axis, the one on the left is typically the drive belt)

If you need to tighten the y-axis belt there is a small hole in the back of the machine inline with the y-axis belt. The pulley at the end of the belt has a screw tensioner that you can access through the hole with a long screw driver.

This happened to me not long ago. My laser tube was losing power. Turned out, the mirror in the tube, opposite from the output end had burned out. I had proper water circulation. When I tested the output beam straight out of the tube I had the same patterns. Unfortunately, this will require a new tube.

As for the motors, I agree with Nedman, check your belt tension. If your belts are good then you may have an issue with either the wiring or the stepper driver on the board. A broken wire can give you this problem when it is flexed and go away when it is not flexed. Also check the connection at the board make sure it is seated properly.

My machine had ribbon cables and those can be delicate.

Also, this may happen if your power supply 12 volt output is failing. It may show proper voltage but not have the amperage to drive both motors.

I hope this helps.

Gentlemen,

Thank you for the suggestions. Yes, the head is supposed to be homing which is at the back left. I will check out the belts. It occurs to me that the noise only seems to happen when the head is slewing and never when it’s making a cut. Could the slew rate be too high? Is there any means to adjust it? I’d love to see a complete schematic of the boards and power supply. It might help a lot.

I have put everything back in the original state, even the funky clamp the machine came with to check out the raster and vector cuts. They are fine. There will be no immediate need for vector cuts, so I won’t be in a hurry to change the tube. I bought the laser for the woodshop I donated to the continuing care community where we now live, so there is no mass production use of the laser. We have many other means to cut material so the loss of vector cutting is not a big deal.

I will also check the current and voltages from the power supply.

Stan

The slew rate looks fine for a homing move. It may only be slipping at higher speeds. Notice that the x-axis motor stops when it gets all the way to the left and engages the optical end stop. The noise continues because the y-axis isn’t moving so the optical end stop of the y-axis doesn’t engage.

If you go to @donkjr 's blog you will find the schematics for the machine and much more.

Ned et al,

IT’S ALIVE!

I took the X-Y assembly out of the machine and found the right-hand Y axis belt was completely slack. I tightened it as well as the left-hand belt and the grinding noise is gone! Thank you, again, for all your help.

Now it’s on to replacing the mirrors and installing air assist. Then I’ll complete the upgrade I’m building using a couple of Adruinos: water temperature, level, and flow monitoring with alarms, a keypad password to start the laser, and a digital voltmeter to monitor the power level. Once that’s done, I’ll get a new tube and put a clamping circuit on the power level to reduce the chances of burning it out again.

Stan

So glad to hear that you got it working.