What is the best lubrication for smooth rods and for Z Screws? We have a couple printers from Open Source Classroom that need a bit of maintenance.

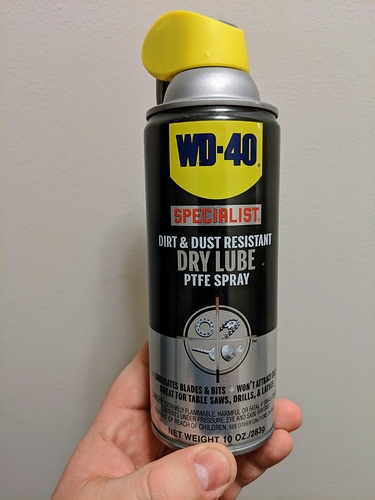

teflon (PTFE) grease. (spray - use food grade if working with younglings)

@shauki you realy should use quality products - how does grease can dry - i would assume you used a PTFE spray not PTFE grease spray? You can use a silicone based grease but i would prefere H1 designation. A silicon spray is too low viscose which are not usefull on sliding systems or screws. (advantage of silicone is the temprature range, medical use and abhesive or water repellent ). Using PTFE is prefered as it has the lowest friction coefficient. Also no difference between static and kinetic friction (µs/µk 0.04) Only synovial is better - Ü

yes as i said these are spays not grease/grease spray. And if it fall off you applied too much - only a very thin film is needed. As forces are low on 3D-printer this is fine for sliding if there is enough surface but i wouldn’t use it for lead screws (or ballbearings). This is what i am talking about https://www.condat-lubricants.com/product/aerosols/ptfe-grease/

@shauki haha yes that is wrong - i don’t know this particular product but the PTFE spray grease i use definately will not dry.

@shauki here what i use: http://www.schmierstoff-online.de/shop/images/Datenblatt%20(PDF)/PRO_620_HL_Produktbeschreibung.pdf

In the US I recommend Superlube grease, it’s a synthetic+PTFE grease formula that works fine for 3d printers and is safe to get on your skin. Many printer OEMs recommend it too.

(I wouldn’t use it for severe service conditions like a car wheel bearing, but it’s safe and no-odor and works fine.)

@shauki this is oil but you need grease (Schmierfett) for a lead screw - oil will flow down as it is to thin (low viscosity). (btw that oil could be not suitable for plastic parts)

@shauki put load and speed on that bearing and it will work with oil only a short time. Why do you think these thick lubricants exist?

@Ulrich_Baer big unshielded bearings like that may have been intended for oil flood lubrication. We just don’t like to put oil pumps on our 3D printers…

@Ryan_Carlyle Sure every engine is working with oil. But submerged in oil not a thin film that will vanish after a few spins. Grease is oil in a matrix as reservoir. If a machine is designed for grease you shouldn’t replace it with oil as shauki is doing. If you use wrong oil in an engine it also will fail … But i also have seen people convinced it would be ok not to use any lubricant on a spindle. And yes for the forces on a 3D-printer a brass nut will work for some time even without lubricant.

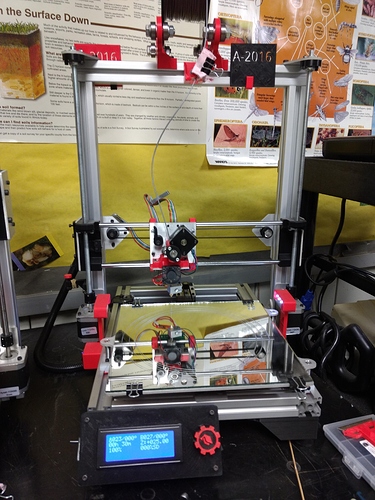

very nice printer ! what type of motors, microcontroller and things to use to do a 3d printer like that ? I like a lot

PTFE spray

@gabcibertech They are from https://osc3d.com/ The designer calls it a FlexMendel. We got them as part of a 3 day, guided, “build it yourself” workshop/grant, for our high school. Motors are Nema 17 and I think the board is a RAMPS.

The OSC is in Bloomington, IL, USA. I highly recommend it. THey also have a Maker Space and other classes.