Well I finished the mdf asian piece. MDF sucks up stain and varnish like a sponge. I bought some sanding sealer to see if that helps. This one took 4 coats of stain/varnish and 7 coats of clear varnish to get the desired sheen. I also have come to the realization that dust collection is a must as the fine dust mad it into the clear coat from the other room of my shop so I picked up a harbor freight dust collector and will be making a collector shoe for the machine. does anyone have an stl for a shoe that splits to allow tool changes. If not I will post details on what I come up with.

Ammmmazing. One day might need you to teach me your ninja CNCing skills!

Best one I have seen:

It’s actually from a R7 builder.

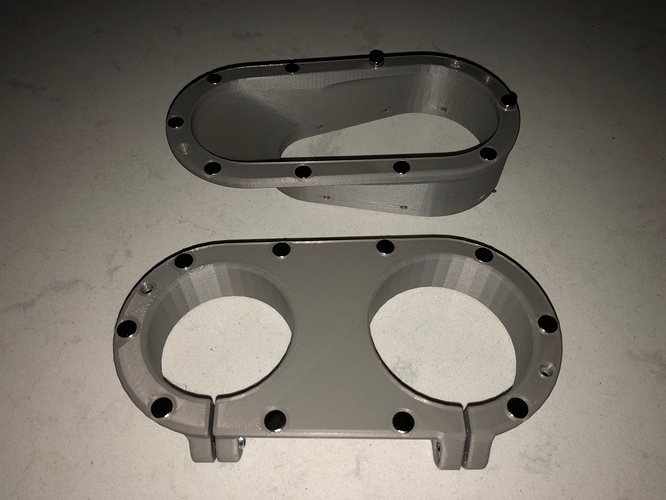

I have one printed now, but it’s a little large for my dust collection (but it might fit yours great).

I’d be happy to print and send you the upper and lower for $20 (my cost and assuming you are in the US). It’s printed in silver PETG. You would need to add magnets, (2) M5 nuts and bolts, and a skirt.

My only problem is it makes you mount your spindle lower. That and the size of the dust extraction (for me). I have a design in my head that will allow mounting on how your (and my) spindle is mounted.

But it might be a bit before I get around to it (probably January…).

I’ll post pics of it if you want. It looks really sharp in the silver PETG.

@Jeb_Campbell That gave me an idea about how to make one from wood. I have a lot of projects ahead of it but I’ll try to get to it.

@Jeb_Campbell thanks for the offer. Ill take you up on it if it will fit the 800w 65mm spindle. Please pm with how you would like me to send you the money.

@Jeb_Campbell I had to check out that link. Before I looked who produced it I knew who’s work that was by the solidworks images. This was made by the great co-designer of the R7 @Eclsnowman . Anything he does is gold!

@BuddahrobSidartha_Ro Sorry for the extra posts, but I need to figure out this Google+ stuff…

Anyway, 65mm spindle confirmed (it fits on mine). The dust port is 2.25". The magnets are lightly pressed in, they need to pop out and then glue in. To keep you from ordering the 8x3mm magnets, I can send them on.

$25 to jebc (at) (the letter “c”) (the number “4”) http://solutions.net – jebc@c4sol… Paypal

(assuming the dust size works for you and you want the magnets, nuts, and bolts)

You would need to add a skirt and the dowel shear pins.

Sorry, I don’t know how to private message here.

Also you will have to mount your spindle lower… The backside of the spindle shoe will not clear the cbeam or end plate (maybe an inch to 1.5 inches lower).

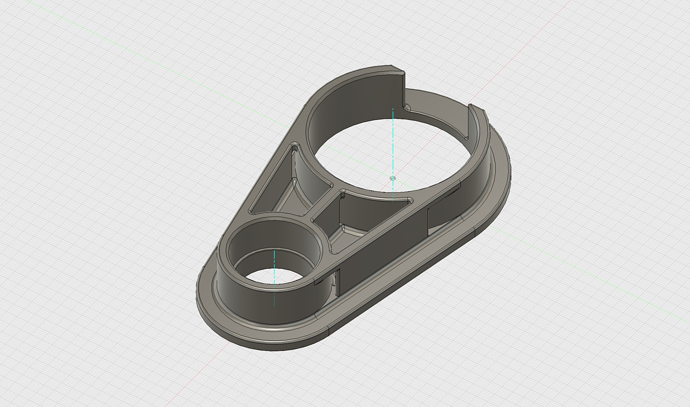

If that’s a problem, please see my next reply with screenshot of a parametric dust shoe that I’m working on that will minimize that.

(I haven’t put the final 2mm gaps in, but it will use band clamps).

Fully parametric dust shoe (notice the 2 sizes in the dust port since I have 2 smaller dust vacs).

The back is cut to allow it to ride much higher on the spindle, then a band clamp to secure it.

@Jeb_Campbell Looking Great. Yeah, my design works on my CNC… but I also have the printed spindle mount that makes that possible. Brandon’s aluminum mount is so compact… he didn’t give me much room to work with making that work with my shoe. Looks like you might have found a great solution.

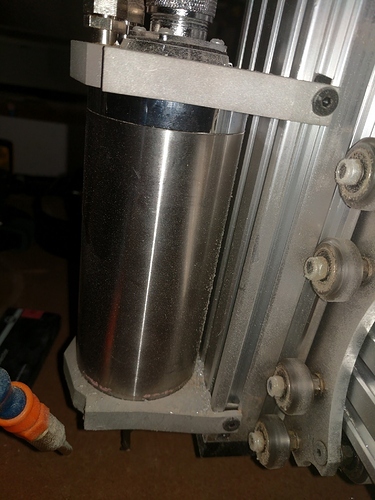

But Brandon has the right idea. Hugging that spindle in tight like Brandon did is the best way to go once you start cutting aluminum and chatter becomes an issue.

@BuddahrobSidartha_Ro In the mail in an Amazon box. I had a secretary at work send it, and I’ll check on a tracking number.

@Eclsnowman hey my northern brother, did you say the dust boot you designed wont work on the newer spindle clamps?

@Jamie_Wilson let’s see what Mr. Lien has to say.

@Brandon_Satterfield yeah, Unfortunately you got that spindle tucked in so close that my design doesn’t fit. I should try to design something new for these guys. I have just been swamped.

If I find some spare time here I will see what I can come up with.

I think some maybe made a modification of it. I just forget who/where.

Edit: Nevermind the modified version… was further up in this very post

@Eclsnowman thanks brother. We have it slated for June. I think I will follow your magnet design for the R7. The OX one we are about to release swings or separates in two halves. It works but the magnets will probably be a cleaner solution.

Believe I do want to go with an adjustable height set up though. Seems pretty fun.

If you get to playing around or if one of the guys on here has produced one. I’ll fully support advertising and selling on here.

Short.