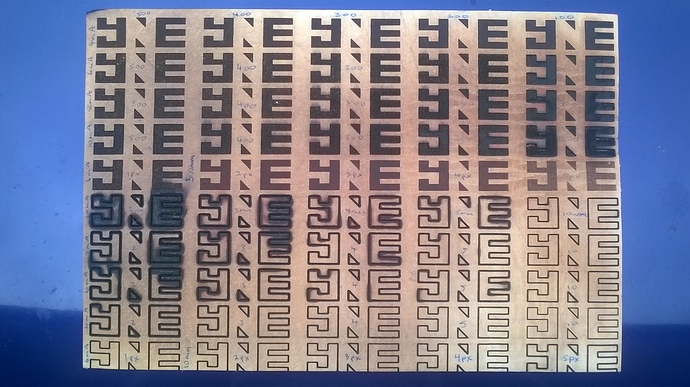

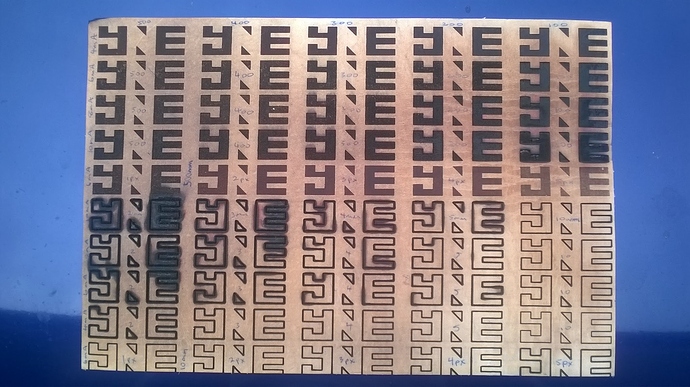

Well here is some tests I did today on ~3-5mm natural vegetable tanned leather.

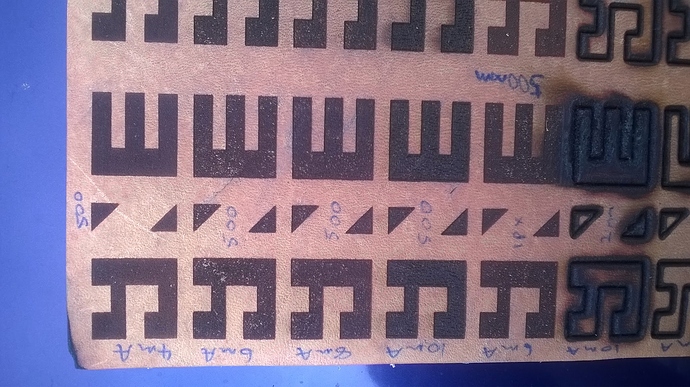

I tested different power levels & different engrave/cut speeds. I also tested to see what the pixel steps option actually does (basically the more pixel steps, the less it actually lasers, so the image ends up faded slightly).

So now I have a reference for what difference it makes doing different power levels/speeds/pixel steps.

Personally, I think I will stick with 4-10mA power, 500mm/s engrave, 1 pixel step.

And I still haven’t managed to cut through the 3-5mm thick leather. Closest I got was 10mA @ 2mm/s 1 pixel step. Looks horrible though and actually charcoaled the leather haha. So that’s a no go. I think another test with 4mA @ 10mm/s 1 pixel step & multiple passes is in order.