Was not going to do this exercise, but saw yet another repetition of “plastic bearings do not work” (and one too many).

Our desktop FDM printers bear light loads and move fairly slowly, compared to the more demanding world of machine tools. We do need precision, but are otherwise undemanding of bearing design.

The (otherwise interesting) video at the point in question:

At this point, was more(!) than a bit annoyed, as the design offered is not suited for making with a 3D FDM printer. We should use designs suited to the materials and method of manufacture.

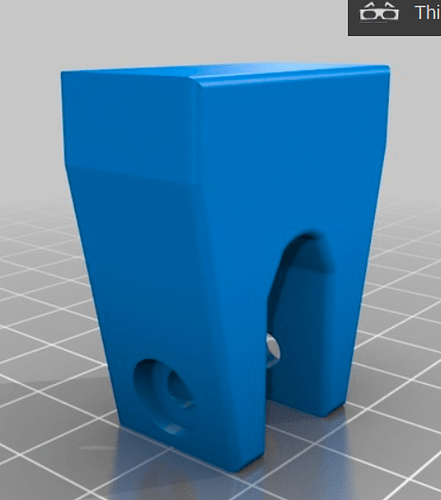

Posted an example Y motion bearing to Thingiverse, with link to the design in OnShape. The example is not meant to fit any specific printer.

I am not inventing anything, here. These are old ideas from examples I saw very long ago (though probably not made of plastic). Too far back to recall the source.

Most 3D FDM printers are simply not accurate enough to fabricate bearings that call for close tolerance. But you can achieve close tolerance in the end with careful design.

There are two design tricks here.

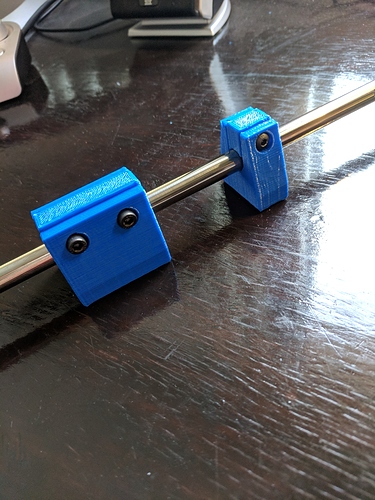

First, there are three lines of contact along the rod. Three points is sufficient to force exact placement of the rod within the bearing. As the two upper points are offset, the weight of the build plate is also forcing exact placement.

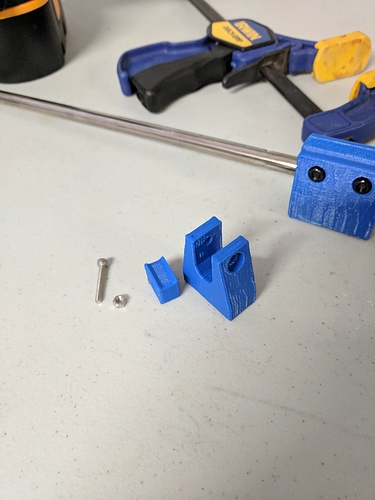

Second, the slot/plug in the bottom allows fabrication with less precision. When assembled, a hand clamp (or any substantial weight) forces the plug tightly against the rod. The bolt locks the plug in place, but does not press against the rod. This is how we achieve very tight tolerances, when our method of fabrication is less precise.

Note the design is for a 10mm rod. The test rod (savaged from an old printer) is actually 9.5mm. The bearing works fine as it is tolerant of small difference in dimension.

I soaked these in a light spray oil (something generic from the local hardware store, that also claims to contain Teflon and Silicone). The slightly porous nature of FDM prints is of advantage, in this case.

Tried both longer and shorter variants. The longer had more static friction, and I do not see any advantage, so uploaded only the shorter. There is no detectable “play” at all in this bearing, and it slides with little effort.