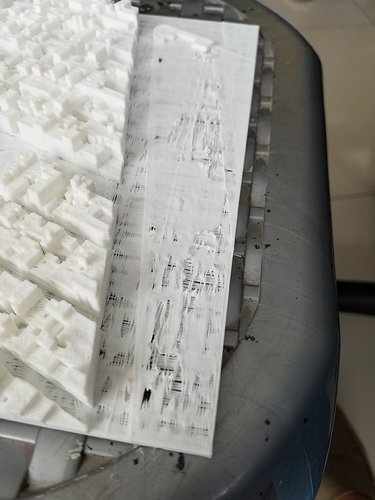

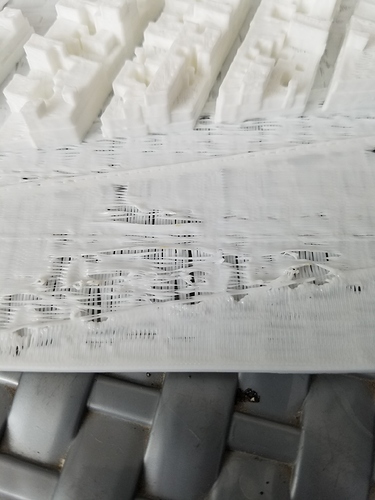

wanhao duplicator i3, we are having issues with the top layer looking like scratches, we are pushing the printer to the limits becouse of printing time.

need to print in the fastes time posible with this machine for a project, any suggestions or solution will be welcome.

I’ve only had that effect with poor quality PLA.

It’s probably from going faster than your extruder can melt plastic. The long straight lines are the most demanding of plastic volume because they’re the only ones that go your commanded speed. The smaller moves are slower than you command due to acceleration computation in your firmware.

Raise the temperature a little bit. It might also be slightly under extruded and not fusing well with layer beneath.

Here’s a tip: A failed print that takes 8 hours is going to require another 8 hours to print. A successful print that takes 12 hours, is going to be shorter overall than what you’re trying. Stop pushing your machine because of some sort of deadline.

Or you could try reducing the speed of just the top layer. M220 is your friend here.

What infill are you using? Increase, or if top layers add more layer to smooth over. Another way, print slower!

Looks like it is printed too fast. Or the feed is too low.

Well put @ThantiK it’s a hard lesson to learn. Took me a long time. Find where you get good results and use that. It’s better to use a little more plastic each print than have half of them fail.

I do not think that you have your initial layer low enough. It should squish against the print bed and it does not look like it is. The faster you print, the higher you will probably need to set your hot end temperature and the greater the chance that you will not have the perfect temperature at every given moment. What @ThantiK said.

If you need quicker print times, consider rotating the object and trying different layer heights and shell thicknesses. Those are three things that can speed things up while hopefully keeping he quality at an acceptable level. If you have multiple objects to print, you can take a gamble and print them side by side if you are sure your settings are dialed in correctly. That can overcome waiting for minimum layer times to pass since you increase your chance of actually printing instead of just waiting or slowing down.

Print slower. Use multiple machines to print so you can increase output over the same time so printing slower is then not a problem anymore.

I really do not think there is enough bed adhesion going on.