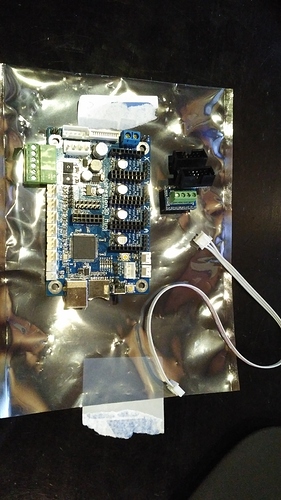

Upgrades part two. Swapping my current C3D board for the latest and greatest direct do in board. To bad I can’t get to until later in the week

@raykholo - What is the cable for on this version? Is that going to be where I tap in for the PWM for the laser?

On my current board we’re using the middle pin on the header just in front of the main power connector on the daughter board.

@Carl_Fisher Same thing as what you’re thinking of. That cable goes to the 3 pin JST on the Mini (between the 2 yellow buttons). The other end makes it possible to plug into my other kind of PSU which has that connector. For you and anyone else of the screw terminal PSU, cut one end of the cable, separate out and strip the middle wire (only this one is needed) and get that into the IN terminal where the center pin of the pot used to be (remove it). Or use a dupont male-male jumper to go from the connector housing (no cutting) to the IN pin.

Carl, for you specifically you can probably just plug your red wire with 3 pin housing into the port on Mini I described.

Beautiful. I’ll convert to using the new cable for the benefit of documenting everything correctly. I’ve done a bunch of wiring cleanup anyway so no reason to keep that odd red wire in the mix that I have now.

Now the next hurdle will be moving the current board over to CNC duty and splitting out 5 drivers

@Eclsnowman Carl has the same “concern” regarding dual dedicated Drivers. Except he also wants a rotary so he needs the 4th dedicated axis. Will brainstorm the best way to handle this.

I assume I’ll just use that breakout board on the Y-Axis socket to setup 2 external drivers on the old mini once I move it to the CNC and that will handle the dual Y motor setup. The biggest hurdle will be finding a way to cleanly mount and integrate the drivers. Ideally would be a board that has a 24v input and screw terminal breakouts for each driver with it’s own socket. Also would be nice to have a jumper to hardware select reversing one of the motor pairs.