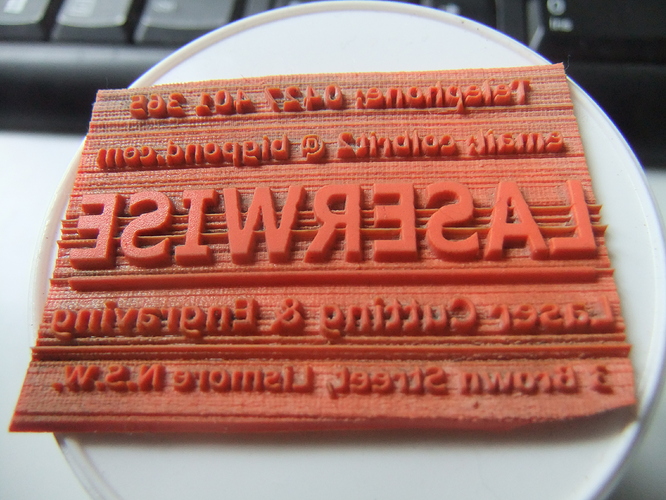

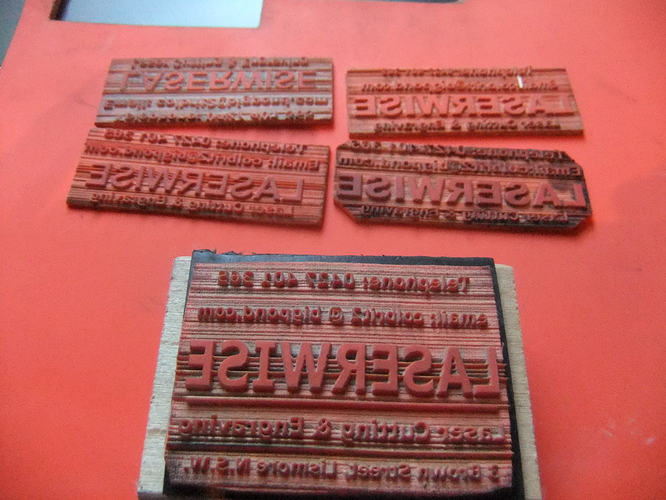

Hi Guys, I have had reasonable success in making a rubber stamp controlling the laser power and speed but I just can’t get rid of lines running across the stamp. Most do not print but there is the odd one that dose. Anyone had to deal with this problem before, any help is appreciated.

Hi Colin @colbrit,

about your request, I try to make my mind between hardware and software, could you tell us more what do you use (original/modified K40 controler, your software).

does the line in question is located inside the big font or under “Laser Cutting and Engraving” ?

Any more clue would be appreciated, … (any other outputs photos ?)

Hi Stephane,

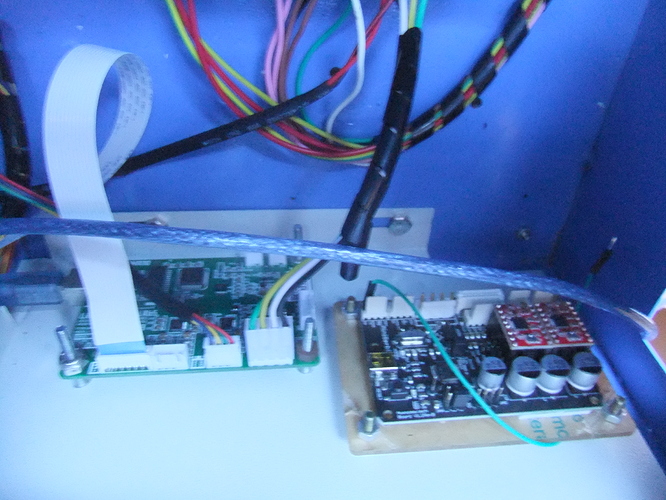

Thank you for such a quick reply. I quite understand what you mean between hardware & software but I have been unable to find much in the way of software for engraving rubber stamps other than Inkscape & K40 whisperer. I like Lightburn but there is no provision for stamp making. Have you found somewhere better? If so do you want to share it? I use as a controller mini-gerbil from awesome.tech which enables me to use Lightburn. If I want to use K40 whisperer I have to revert back to the controller that came with the machine from new. So to do this I have both controllers installed side by side in the machine and swap the wires when I need to use whisperer. I hope all this is making sense to you as I’m not that good at explaining things that well.

There is one line that is meant to be there and that is under LASERWISE the rest just get formed in the engraving process. They are below the printed surface but only just and some times print as well. There should be no other lines in the stamp at all.

I was using the proper rubber meant for engraving with the settings of 60 mm/s and 12Ma

When you are dealing with lines, it’s always a good idea to rotate 90° the design.

If you consider X axis the long side of the bed (horizontal) and Y the short side (vertical).

During Raster the head move on X, if you have a slight offset belt issue in Y, the problem will still be there after 90° attempt (vertical), but that will discard a lot of other possibilities (software, design,etc… )

You don’t need to waste more rubber for that , should be the same on some waste wood.(visible line in raster)

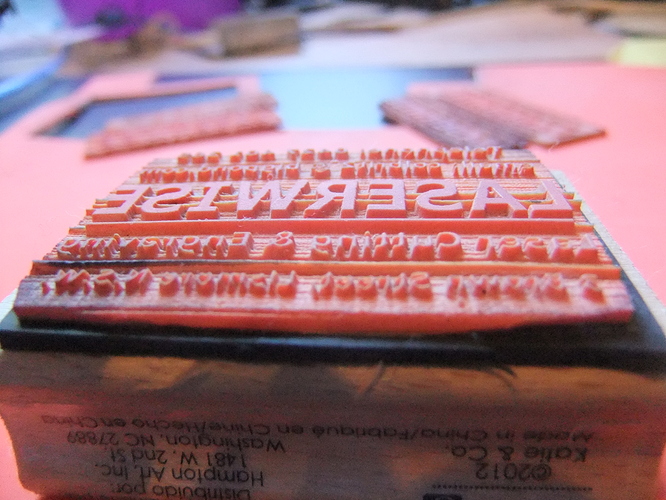

Focus point:: I am not experienced with rubber, but the focus point depth is here essential as you want 2 levels. So you need to find the right balance. A ramp test on rubber will help you with that.

Also in file preparation , I suspect the DPI parameter should be important. (affect the number of burning on each overlap of every defocused points, I mean from a line to the next).

Thank you again Stephane, you have raised some very interesting points that make a lot of sense and I am looking forward to trying them out tomorrow. Will let you know how I get on.

Cheers Col

Are the lines random or do they always appear in the same place for each stamp? What material are you using for the stamps? I’m wondering if it could be some inhomengity in the material.

Hi Nedman, the lines appear not to be in the same place, After reading your post I have been checking for this but because I have been placing the rubber in different locations I am not 100% certain. I think I might have found the problem in the lens. I had taken it out to clean a few weeks ago and found the cap around it hard to screw back at the time. I took it out to clean this time and found I had damaged part of the edge around the lens. I must have done this when I found it hard to do up last time. So I am waiting for a new lens. Heres hoping and fingers crossed. The rubber I used was from company called PULSE laser systems and was made for lasering. Thanks for your help.

Hi Stephane, I did manage to get a much better result until I took the lens out to clean and found that it was damaged around the edge. Which was my fault from previously cleaning it. I also found that you were right about the focal point and I sort out where to find a sweet spot that worked best. Thanks again Stephane. I am a retired letterpress printer and should (better still MUST get this right) lol