Hey,

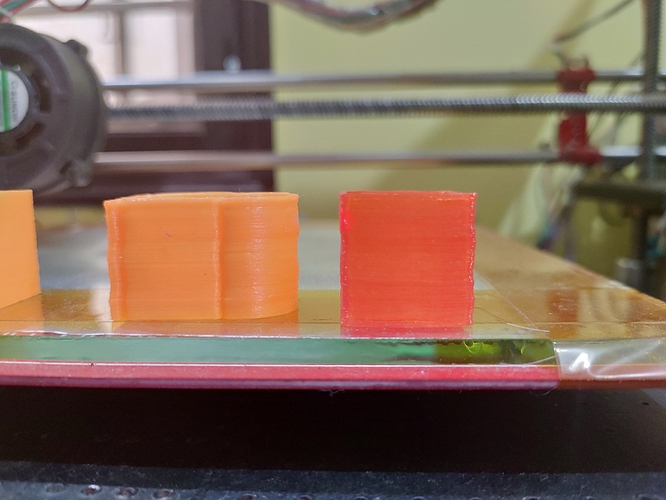

I built this kickass fully hand made 3d printer which i call it the ‘Rex_1.0’ and runs on marlin firmware.the dimensional accuracy of my prints on the XY plane is spot on but when it comes to the z plane the layer deposition seems to be uneven,which looks like a leaning consistent zigzag pattern on the Z plane of any print i try irrespective of the filament material i use.this is mostly noticable when i prints like the calibration cube.i read in many forums that this might be due to loose belts,gears and other moving parts…but i use lead screws for all 3 axes and hence not a belt driven system.I have double checked for all the possible loose joints and screws and all of them are as tight as they should be.i’ve also printed them at super low speeds as low as 10mm/s just to take speed, jerk and acceleration factors out of the equation.the z offset and structural alignment of the machine is right too.ive changed the nozzle, played with different temperatures, z height, babystepping and also different slicer settings too and still the problem persists…ive tried all possible soultions so i really need you guys to help me find out what I’ve been doing wrong!

That must be frustrating!

Two initial questions:

- How did you validate that the lead screws aren’t bent, even slightly?

- Are you using anti-backlash nuts for your X and Y lead screws?

To give folks here more of a chance of helping, please add some more pictures and information.

- Pictures of the whole machine from a few angles might give people ideas what else to check.

- Very carefully focused pictures of a single calibration cube from multiple angles. The focus isn’t good enough in the first picture you uploaded for me to see individual layers.

Those might help others ask more informed questions.

Thanks for the response,

The closest i can get to saying that it isn’t is just by visual inspection cuz i have no precision guages and kinda sure that they dont seem bent.I bought these ss rods from ali express and are made specifically for 3D printers.

And No, I am not using anti backlast nuts although i have them because axes mounts I made weren’t designed keeping them in mind my planning sucks.but there isn’t any backlash when i try moving the mount.

I tried uploading pics earlier but i wasn’t allowed to upload more than one pic…even the google drive link didn’t seem to work on this.I might be doing this wrong as i just joined this forum a couple of hours ago…so i am still figuring out how to do it.

Ah, it’s an anti-spammer protection built into the Discourse software that runs this forum! Spammers mostly don’t wait long enough… If you haven’t already, please run through the tutorial that @discobot sent you when you joined.

I have received bent lead screws. Rolling them on a flat surface (the flatter the better) will make it relatively obvious if they are substantially bent. It’s a rather common problem, and it doesn’t take much bend.

It doesn’t take a lot of backlash (you might not notice it), and trapezoidal lead screws will have backlash; they would bind otherwise. The anti-backlash nuts push back and for X/Y on a printer will typically be sufficient to manage backlash. The alternative is the much more expensive ball screws, which is why they exist.

I’m still getting used to what a new forum member can do on Discourse: can you try uploading a picture of your printer in a reply? I think you can keep providing new uploads in the conversation.

ive clicked a few more pics hope this link works…https://photos.app.goo.gl/URxWG4RBRd6rfjwi7

Its my first time in 3d printing and this is all hand made…made of polypropylene sheets.i get your point about the bent rods will check them.thanks

Thanks for linking to the album. The link worked.

There were at least two possibilities I saw initially; the layers were shifted, or layers were not all the same thickness. As far as I can tell from the album you posted, the layers are shifted, which I would expect with not using anti-backlash nuts and trapezoidal lead screw. I think you’re going to want to find a way to redesign to use anti-backlash nuts. It will be cheaper than buying ball screws!

Thanks a lot for the help…will try out the anti backlash nuts and hopefully i wouldn’t have to bug you again  which i might ending up doing.

which i might ending up doing.

I moved this post to the custom sub-category, FYI.

Good luck with it! Part of the fun part of making up a new printer is wrestling with the unexpected. I’m sure you’ll end up learning lots of lessons beyond this one.

Definitely post here with what you learn!