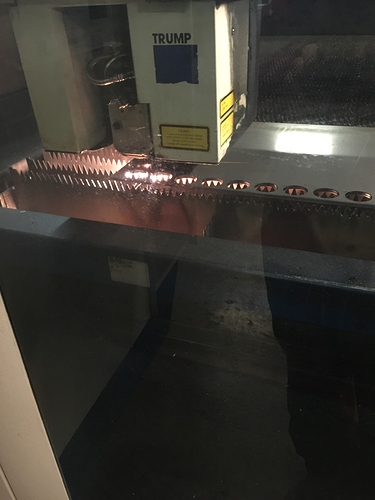

My laser porn

Nice Machine, yours? or you want it to be? Work?

From work

We have few trumpf’s

6kW co2 3020

5kw 5020 fiber

4kw co2 3530

5kw 7040 5axis

3.2kw tubematic

4000 bar byjet smart

And few other

So mainly i have contact with laser all days since 1999

LOL. That looks like the bed I put in my K40. I used those mending plates from Home Depot - they have pointy spikes you hammer into the joist. http://m.homedepot.com/p/Simpson-Strong-Tie-3-in-x-6-in-20-Gauge-Mending-Plate-MP36/100374920

+Peter van der Walt i need to do closer look over your p3steel variant,now i have two working graber’s.weak point of them is x axis

The Trumpfs seem to be popular in the US, I used do industrial control work, and ran into a lot of them, never a 6kw though. Fiber? I was sidelined by a health issue in 98, so left the business when you started. A kw was a big deal then. You see them in HGR used equipment emails now and then. Still out of my range even used and abused.

@Scott_Marshall

In this year we will get another fiber one

http://www.uk.trumpf.com/en/products/machine-tools/products/2d-laser-cutting/laser-cutting-machines/trulaser-5030-fiber-5040-fiber.html

Im in uk.its always possible to do jobs

Or if its small job and you have dxf i can do straight

Yes we do that

@Damian_Trejtowicz That’s quite the machine. 20mm capacity in steel and full sheet capacity. Probably the ultimate tool for cutting sheet stock for manufacturing. That’ll take a couple months to get installed and running. Enjoy it, I really miss the work, saw some wild stuff and learned a lot. I didn’t really appreciate it until I got sick and it was over.

Guess that’s why I play with with small machines.

Scott

When we order machine and arive ,its take about two weeks to start using.the biggest one what we have its 3050 l20 from trumpf integrated with fully automated loading and unloading system trustore and liftmaster sort

You must have quite the team. 13000 Kg is a bear to set.

Looks like a great company to work for.

Scott

Hi, working on a trumatic 600l machine and having real problem with rh kerf, trying to make part smaller or bigger using kerf, but it won’t change, can anyone know how to fix it or if there is another way to control the size of the part?