hi, thanks in advance if you read this. how does one manually find a gcode to align your work area on an etcher WITHOUT lightburn?

ive been searching web but i guess im not asking the right question ( or version of).

im a bit challenged still, to try and write my own. sorry

It may help to tell us more in detail about your problem and what you are trying to accomplish.

I would like the gcode to draw a line around the total work area. To help align my project. I’m terrible understanding gcode. I’m using marlin. M106 command for laser on. If that helps.

You’d need to calculate the bounding box (or outline or rubber band outline) of your tool paths and then generate the g-code to move along that at some speed.

Why don’t you want LightBurn doing that for you?

Framing isn’t strictly necessary for alignment, by the way. You can also do all of your alignment with indexing features which have a known distance from the homing location. That’s how I generally do it. I just push the item with known dimensions into my 0/0 corner and just start a job with matching dimensions from 0/0. Or I use a jig which makes use of some indexing features.

As far as I’m concerned, framing is just for doing quick sanity checks. Everything should be already perfectly aligned at this point and I just press the frame button to confirm that everything is indeed where it’s supposed to be.

Check the LaserWeb docs to see if there are any exposure of internal variables like CNCjs has( User Guide | cncjs search for “variables” ). There is even an example of how they’re used in GCode. Hopefully LaserWeb has the feature.

Again thank you but some of its above me. I shall google

@tomatsu @dougl @donkjr thank you for the wealth of knowledge. To answer as to why I don’t use light burn is that it’s too complex for me right now. I currently own two lasers. One is a Creality cv-01 very simple ( only decent) for my learning curve. I built a larger scale model to advance but I trashed my control board setting it up. I think I jumped too fast to the next level without learning enough basics. So I backed up to concentrate on “use of” type stuff. I got frustrated looking for a simple piece of code to try it and poof here we are.

People, it’s kind souls such as yourselves that make traditions continue! Thank you

I think the mention of lightburn at the beginning obscured that you asked in the LaserWeb/CNCWeb category. ![]()

In general, as far as I know, using an alignment jig has been the classic solution for close alignment, regardless of software.

I definitely will look into that. Actually makes sense! Thanks people

As @mcdanlj has mentioned, a ‘fixure’ or ‘jig’ is probably your best option.

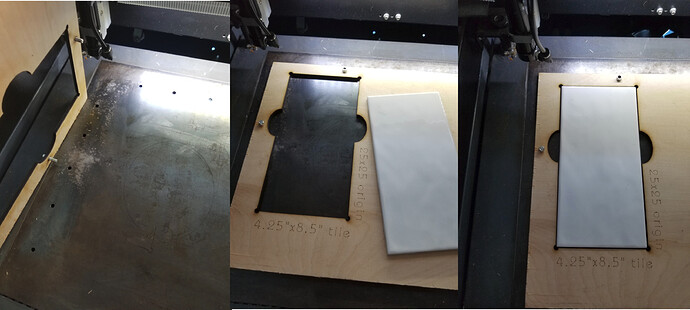

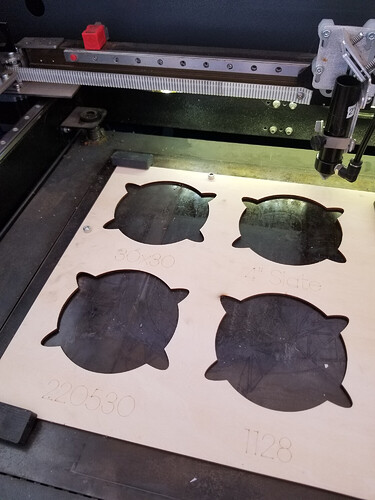

I have a 50W co2 with a steel floor with alignment holes…

Here are a couple of photos to give you an idea…

Good luck

![]()

LaserWeb has the function “check size” which moves the head around the work area ouf your file.

For diode lasers, you might manually activate the laser on very low power before starting “check size” to get a better view.