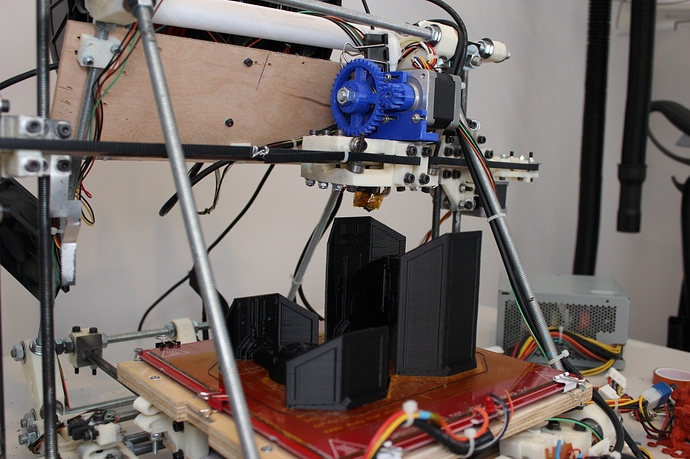

This print was interesting. I have some ABS glue on my kapton (printing ABS). I heat my bed to 80C as the thermistor reads it. This did warp, but the ABS glue really stuck it to the kapton so much that the kapton was pulled off the glass in a big ring bubble around the center of the part. I’ll have to re-tape my bed, or forgo the tape and just use ABS glue from now on.

More importantly, where did you get the Vadar tie fighter model from?

Glass + hairspray = yup

S’wot i use when printing abs, anyway

I did sense a disturbance in the Force. Everything is revealed.

- Hooooo *

- Aaaaaaaah *

Back to topic, Lulzbot uses PET tape rather than Kapton. They say it sticks better, and it’s thicker and more durable. I’ve never tried Kapton, as a matter of fact I’m still using the PET that came with my AO-100 5 months ago, but I haven’t printed much.

@Tim_Rastall I gather this is the Tie you’re looking for. http://www.thingiverse.com/thing:14480

Gotta print this as well! Gotta rainy 3-day weekend ahead of me (Canada Day on Monday), so I might find the time. Odd people are we 3D printing nuts who welcome rainy days.

@Nathan_Ryan I used hairspray on glass for a time but found out it shrinks the bottom layers. Might not be critical for vases and Yoda busts but for mechanical parts it’s not good. So I went back to PET and started using Lulzjuice (ABS+acetone glue).

Shrinks by how much? I’ve been using it for awhile and I haven’t really noticed much in the way of shrinkage.

Cheers @Normand_Chamberland :). For what its worth. I’ve given up with kapton and just use ABS slurry on Aluminium.

with abs glue and kepton i can print on 65 degrees

I missed the comments on this until now, sorry! @Normand_Chamberland has correctly identified the model used. This was part of an open house I held to show people in the neighborhood, so I collected some neat prints on Thingiverse that I printed all through the week, ending in this.

@Nathan_Ryan

I just posted this in 3D Printing. https://plus.google.com/117324667497119008450/posts/AFvXJPKE1mt

The gap between the two parts is almost 1mm. They’re 6.35mm thick.