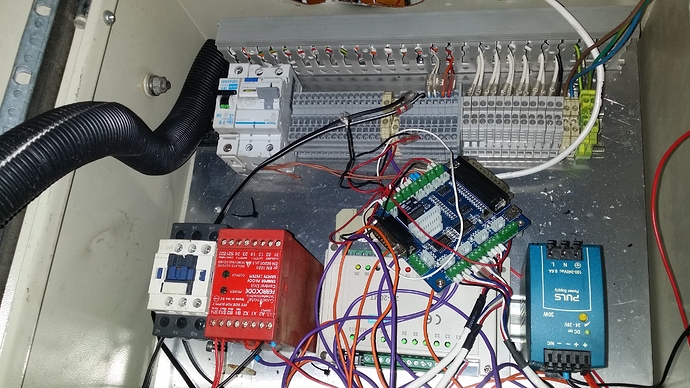

This is the rough in of the control box. The wiring loom is terminated to the terminal strip. The next step is to install the last piece of din rail and the slotted cable duct. Then fit all the peripherals in and wire them up. I work 7 days a week so I only have a couple of hours a day. I hope to get the machine running again in two or three days.

Looks very good. Please tell me the type of the BOB.

Looks good. Is one of those components on the lower din rail the inverter, or you mount the drive for the spindle separately?

@Jim_Fong USB for machine control? USB is a polled bus so timings are not guaranteed. Though if the USB data is fed to a microcontroller it can handle the timings itself. That’s how GRBL works. But some find that an unnecessary layer compared to just doing things right. Many more are still willing to put up with the limitations that creates though for the convenience I suppose? I’ve heard GRBL’s predictive speed ability described as, “non-existent” for example. But getting a full featured motion controller to work can be a bit of work itself. So I can see why folks would rather skip the effort.

@Paul_Frederick I’m not the original poster of this thread. I use Mach3, LinuxCNC and UCCNC on my machines. The breakout board used by the OP and the one I use, have a USB connector on them but it is only for supplying +5 volts for the octal line drivers. No USB data is transferred.

It is a standard DB25 parallel port hookup on these simple breakout boards for step/dir

I also use grbl/smoothieware and have tested out quite a few others. I really like the low step jitter as compared to PC parallel port. It really does make the stepper/servo motion much smoother.

I’m using the same board. That’s right, USB is only for 5V power. Now I’ve buyed an UC400ETH. This adapter have 2 internal printer ports and is controlled via Ethernet. It costs about 110 Euros. I think, this is a really good price.

@Peter_Spiess Did you also buy UCCNC? I’m using a UC300eth on my gantry router. You can use Mach3 but the Constant Velocity performance of UCCNC is worth the $60 or so cost.

@Jim_Fong how does jitter affect smoothness of operation? Here it only impacts the max step rate I can achieve. My machine is smooth going faster, or slower though. Are you saying if I could achieve a faster pulse stream than I can even use things would be smoother? I don’t max my machine out now - as other factors besides jitter limit the top speed I run. I’m just not seeing how that could possibly be. Maybe you can explain it to me though?

@Paul_Frederick jitter is the uneven pulse width stream. If you are using Mach3 parallelport , Windows can put slight timing constraints on the pulse width. You want each pulse width to be same. Since there can be background tasks happening, individual pulse widths can be a few microseconds off or more. That is why external hardware pulse generation is becoming popular. You have micro controller pulse generation such as grbl, tinyg, smoothieware and Better FPGA units such as Mesa for LinuxCNC and UCxxx series for windows.

Having done both, you can hear and see the smoothness that a motor runs with good pulse generation hardware compared to standard parallel port step output.

I should add that I still use parallel port step generation on three of my machines. They are bench mills with limited rapid speeds. Max step pulse rate under 15khz. The parallel port is adequate and I have no issues. My high speed gantry on the other hand greatly benefits from using external pulse hardware.

The gantry steppers are spinning 1500rpm. The z axis servo even faster with 4:1 pulley reduction. This requires pretty high step pulse rates that the parallel can’t achieve reliably.

@Jim_Fong you think the port signal has jitter? Well if it did then real time would be worthless. Jitter is internal system timing variations. Computers are God damned complicated beasts. This does lead to some changes in signal timing. But a RTOS works to manage that. That is their reason to be. Jitter is what determines your minimum pulse width and your maximum frequency. But inside the operating range the signal output is perfectly clean and jitter free.

I’ve seen this for myself using an oscilloscope. Now what has lead you to think otherwise?

@Paul_Frederick windows XP (what Mach3 recommends for parallel port step generation) isn’t RTOS. There are plenty of documented cases where windows parallel port pulse generation timing is off. I can see that with my own scope when the PC is under high CPU load.

@Jim_Fong well there’s your problems then. You’re using broken software on a broken OS. LinuxCNC is a fork of the same NIST EMC code as Mach3 is and it works flawlessly. You just have to configure it properly using the jitter value from the latency test and all will go well.

Real time is a funny thing though. When the software is right then latency is hardware influenced. Some high end hardware does not have particularly good latency either. All that extra pipelining and sophisticated prediction doesn’t always help out.

@Paul_Frederick oh I’ve used LinuxCNC since the old EMC days I know the history very well. I’ve compiled and run EMC on 486 computers (on second thought not 486 but Pentium2’s probably) over 10 years ago. Its been so long I forgot. It’s great software but still has its limitations. Parallel port software step generation is only good for around 50khz, maybe a little more. Depends on how good your PC is. It won’t handle the high step rates I require on my gantry without hardware step generation. That is why Mesa offers a series of PCI and Ethernet LinuxCNC compatible pulse adapters.

I still keep a LinuxCNC machine on my bench to test stepper and servo drivers. Thats only good for 50khz or so. Smoothieware is good for 90khz. Grbl-lpc is around 200khz. Faster than that , I use my Tek freq generator.

I still use Mach3 parallel port on my bench mills since it works and hasn’t broken in years. I got so much better motion hardware here I can change them out but I don’t bother. Also because I don’t have to teach my brother how to use a new controller system on the mills.

Many many years ago, early versions of EMC had really poor step generation. It would cause the steppers to stall/loose steps at low speeds. Caused all sorts headaches and scrapped parts. I needed parts to be made and purchased MACH3. Of course EMC got better and became LinuxCNC. Funny thing is Mach3 is still running those same machines till this day . That was the reason why I own a Mach3 license.

@Jim_Fong that is pretty funny considering how sketchy Mach3 really is. I wouldn’t let Windows run a coffee pot personally. As you yourself has pointed out Windows is not exactly a RTOS.

@Paul_Frederick yep Mach3 isn’t perfect by all means but I’m not asking much from it though, about 15khz max step pulse. Which windowsXP and Mach3 can handle just fine. My Brother is almost 60 and doesn’t like change. I’m 52 and getting to the point where “if things work, don’t mess with it”. I got tons of other industrial motion systems to mess around with instead. Lol

@Jim_Fong that’s good. Just so long as you realize what Mach3 does is unique. Even the author of the software Art Fenerty got sick of the stuff and ran off. They say he retired but that’s not how I remember it. Plus he has ArtCAM now. Which doesn’t sound like how a software developer retires to me.

@Jim_Fong @Paul_Frederick Great discussion guys. I am running Mach3 on a Windows XP machine 3.2Ghz 2Gb ram HP ex government slim desktop. That is what I have at the moment. My ultimate plan is to have a 5 axis machine with 250mm cubed machining zone. I know Mach3 cannot handle this how I want it to but as this is early days I have a year or two to go. I am examining all types of motion control boards and I actually have some programming experience in outputting to the parallel port in C.

I am also looking at different operating systems and I can tell you now the next machine will have Ubuntu as the OS and I do understand Ubuntu is not true rtos also. I have two working machines now and this current project will add a third machine to the inventory. I have been into CNC for just over two years now so I am an amateur at the moment. I have about 7 Parallel BOB and 2 or 3 grbls. So lots of fun ahead.

@Jay_Polo The spindle power and control components are not in the control cabinet yet. That is a whole separate section of the enclosure. I am sure you will be surprised.