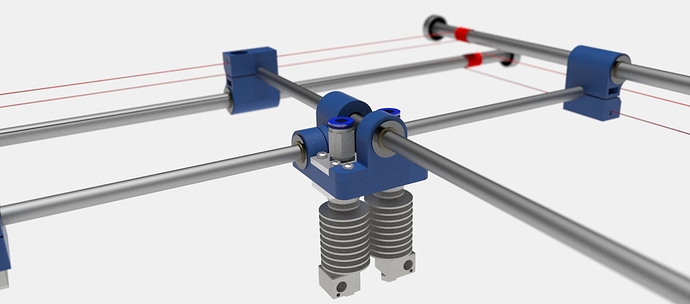

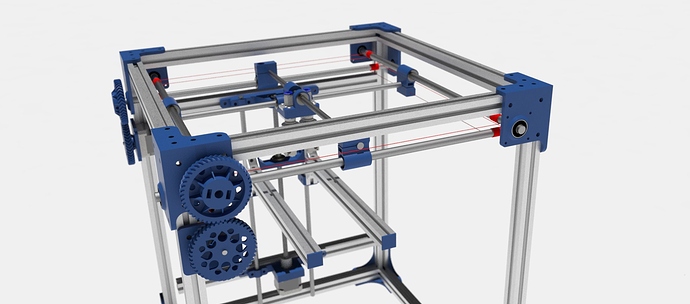

Think I’ve finished the mechanical design for the Big Tantillus. Gave up with GT2 drive belts between motors and rods in the end as I couldn’t find GT2 pulleys with a 10mm bore size (the external rods are 10mm) that weren’t prohibitively expensive. Also got the Carriage footprint down to only 10mm larger than the original Tantillus but with 2 E3D Hot ends as opposed to 1 J-head. Still need to decide on where the electronics, PSU and extruder mounts go…

Nice model of the E3D nozzle - what CAD package are you using her?

Maybe it’s a common practice, but I always thought you wouldn’t want your linear rods to turn inside the linear bearings. In my experience they do move relatively easily but I felt some drag and the bearings I have aren’t designed to have the balls turn that way. If it works well it simplifies things greatly though. Anyone with experience care to comment?

@Anthony_White Rhinoceros 5 (edu). E3d have a model on their site but it was a weird format so I ended up doing it from scratch based in their 2d plans, just a bunch of curve extrusions so not an arduous task. If you want it, just let me know what format.

@Ben_Malcheski I’m using sintered bronze bushings which are designed for rotation as well as linear motion. This is the same approach as the Ultimaker takes so its pretty low risk. Original Tantillus uses printed PLA bushings btw.