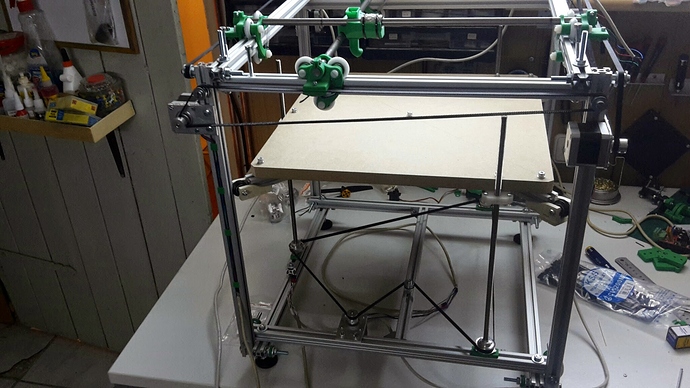

The current experiment im doing on Motedis QR 500, is to use 3 M8 leadscrews to drive the z-stage up and down.

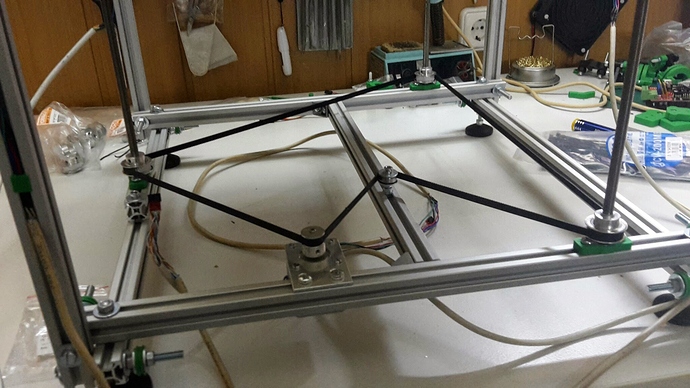

The belt i used for this is GT2 1524mm. On the motor its a 20 teeth pulley and on the rods 40 teeth pulleys. So its a reduction of 1:2 . My thought on this is, because of reduction the belt has to travel more way to turn the 3 rods. This means motor needs less power to turn and precision loose because of eventually flex in the belt is also less.

I already use this z-drive on a smaller printer where it is working pretty good. First test on the Moedis500 went good as you can see in the video.

This mod is only for people with access to a lathe since the ends of the rods need to be turned down to 5mm. I tried to put M8 rods directly into 8mm bearing, but it gives no good precisioen since M8 rods are a bit smaller than 8mm in diameter.