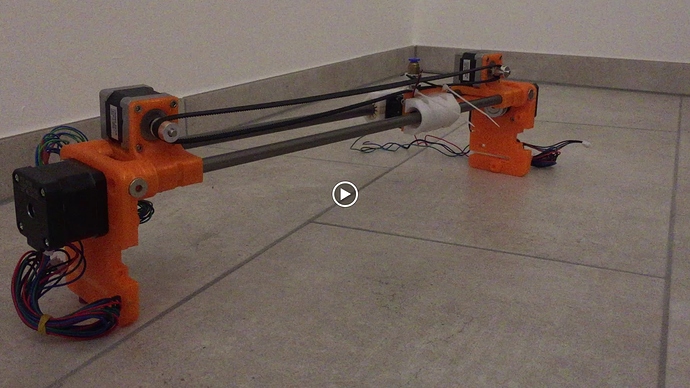

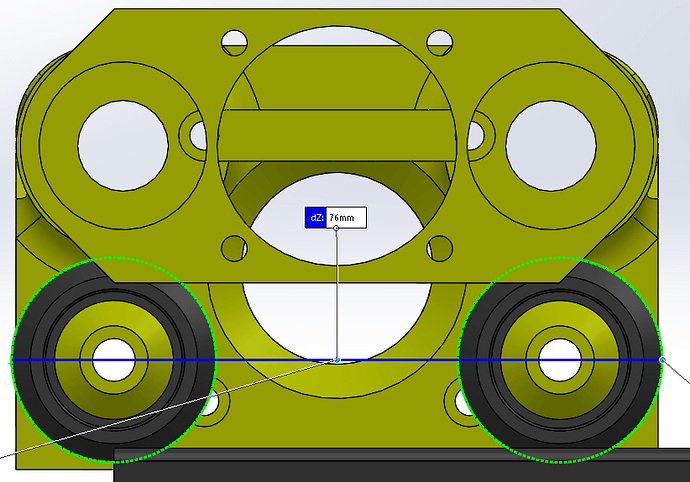

That is the gantry I’ve made for the OpenMultibot: 2xNEMA14 for Y + 2xNEMA17 for X. Total width is 76 mm. Can test when build the frame. If you know narrower solution please let us know.

That’s a sloppy belt. Tighten that up please.

Why 2 NEMA 14s? Too much extra wiring. I’d just do a single NEMA 17.

Tightening the belt takes place after the gantry is mounted on the frame and there are 3 tightening possibilities.

Twins evenly distribute the dynamic loads between the two sides of the frame and work better than a single side drive made in QuadStrap on GitHub.

A NEMA17 (instead of 14) increases the total width and levels higher the belt hook on the Y-slider.

76mm total width seems weird to me. Typing mistake?

Also, tried to get more info about the OpenMiltibot, not much luck. Do you have a link to other elements of that project?

Hi Shauki

Looks great!

I am tinkering with 450mm MGN7 guide rails and cannot get much better than 507660mm by the time all the parts are in place so your dimensions look good.I hope to post some pics in the next few days. Your build is much bigger than mine, so you need to forgo some width to in order to retain stiffness.

No doubt they will yield a bit with experience, but with a multibot you are ultimately limited by the motor size unless you go for a pulley

and cable system.

I’ve tried nema 17 pancake motors (17 and 21mm body height), but you get a 42mm cube by the time the shaft and pulley is added. This puts an ultimate limit on the gantry size.

Smaller motors lack torque and will need gearing to drive the load reliably and fast. I’ve only got Nema08 motors which can co very little without gearing. I’m thinking of RC continuous rotation servos with encoders. That means software and electronics changes, which is probably a requirement for multibot anyway

The cooling towers and filament feed path are also a limiting factor, and probably need redesign for multibot where narrow gantry is indicated…

@shorai all my builds go through refactoring and looking at pictures of what others did always helps. My priority now to install the second gantry and start programming. After adding third and forth one and making narrower ones only matter of time. Thanks for you considerable feedback!

@anon57870006 - Yes, I do that too. At this point I need to get something working on 12V as we have scheduled power cuts of 4 hours as frequently as 12 hour cycles.Programming is going to be fun. I have a few ideas, and was professional software developer for many years. My design is VERY modular and pluggable so that I can experiment cheaply, quickly and easily. I want electronics and software to support a 2019 solution.I feel we are still using a 1960’s implementation.