Thankyou @Elliot_Foster

Umm, cool. What exactly is it?

@shauki I hope so. I’m really loving PETG.

It’s strong, no warping, easy to print.

The layer adhesion is unbelievable. Not so easy to finish the part after printing, but you can’t have it all, I guess.

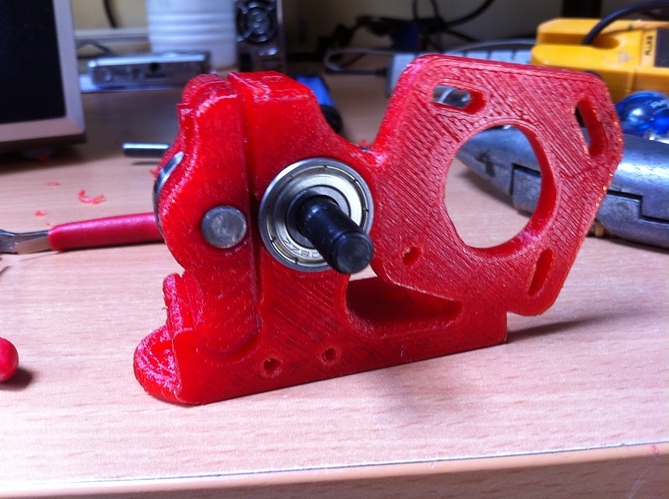

Ha! You’re very welcome, @Rien_Stouten ! Also thanks to the eckertech folks for the beautiful file.

One thing I’m curious about is PET/PETG’s glass transition temperature… Do I still have to worry about my printed parts getting droopy in the car on a sunny/hot day?

It’s in the neighborhood of 70-75C, better than PLA but not “high temp” like ABS

I guess what I’m asking for is for someone to come to my house and measure how hot it is in my car.  But seriously, have people had issues with parts sagging after sitting in a hot car? PET’s 70-75 doesn’t seem that far from PLA’s 60-65… Is it far enough?

But seriously, have people had issues with parts sagging after sitting in a hot car? PET’s 70-75 doesn’t seem that far from PLA’s 60-65… Is it far enough?

@Elliot_Foster I can’t answer if PET will sag in the car, what I can tell you is that here in Australia on a warm summers day a parked cars cabin temperature will easily hit 75+ degrees C, if that info is any help to you.

The dash can hit temperatures of 110c during a hot day, depending on the slope of the front and rear windshields and incident sun. Typical interior temperatures are more like 80c in the cabin area. Hottest zones are the top of the cabin area, and the windshield rakes.

@Elliot_Foster The PETG I’m using has a Tg of 80 deg. C.

For a extruder that should be enough. Especially since I’m cooling the motor with water.

I did have had problems before, with a ABS extruder. The motor got so hot the extruder started deforming. Some of the screws were being pulled trough the plastic. The cause of this is probably the high current I’m chasing through the motors, 2,5 A. Not using stepsticks. My motors only stall if I hit an object, like the frame.

I wonder if PETG can be annealed. I printed a sun visor garage door opener clip in PLA. It sagged in my car initially, but then I reshaped it with a hot air gun and then annealed it in 80C hot water with a 2 hour cooling ramp down. The clip has now been on service for more than a year (including being parked in the sun when it’s been up to 40C outside) and hasn’t deformed at all.

The visor area is probably cooler than the dash though.

@Rien_Stouten What PETG are you using?

I’m looking for an alternative to the all-PLA parts of my main printer, as I’ve had terrible luck getting any kind of decent print quality out of ABS.

@Elliot_Foster REALl PETG.

http://reprapworld.com/?products_details&products_id/722/cPath/1590_1678_1698#.Vb0Ko3gZ3mo

But since today I have a spool of Esun PETG, because Reprapworld.com made an error. So maybe I’ll try that. I’ll let you know.

What kind of problems did you have with ABS? Apart from warping like hell.

Warping like hell is the main problem, yes. The last time I gave up on using ABS was when trying to print some GT2 teeth which ended up curling so much that they didn’t grab the belt at all. Parts like https://github.com/elliotf/prusa-i3-x-carriage/blob/master/x-carriage.stl and https://github.com/elliotf/corexy-printer/blob/57c7ee0760b9217468d0f5704b21cb1afc26b9f5/belt_tensioner.stl .

I fully admit that ABS requires different techniques and more to learn, but also, it stinks and it’s slow to print (due to waiting for the HBP to get up to temperature) which make me less inclined to learn.

Ah, yes, PLA is better for small details.

But yesterday I printed a GT2 pulley (80 teeth) in PETG. The teeth didn’t come out as crisp and clean as with PLA, but it was usable. It should also be possible to print in ABS, I will try that this week and let you know the results.

For letting ABS stick I use hairspray on a heated bed, and for small things, that works. For bigger things I use the +Shauki B method, double sided tape.

PETG does not have that problem. I’ve printed things more than 400mm wide, only fitting diagonally on my bed.

No warping, using hairspray. on a heated bed (60C)

The biggest advantage in printing ABS IMO, is cleaning a part up. It’s so easy to sand down to a nice finish. PLA is a bitch for that, and PETG is not much better.

So when I need something that has to look great, I still use ABS, not PETG, and not PLA.

One small problem with PETG is support material. The layer adhesion is so good, that even the support material is sticking too well to the part. I will have to play with my slicer settings to make that work better.