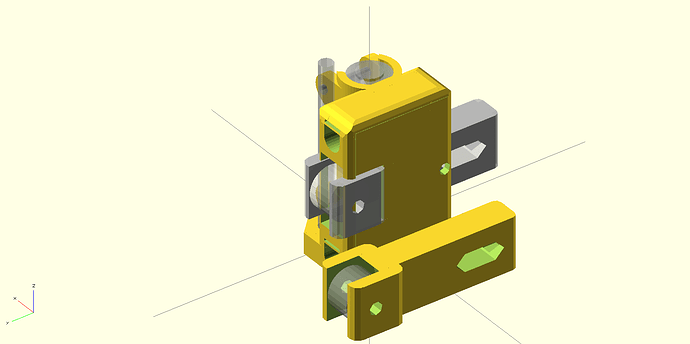

Tensioning idler on X axis, take 2 #Prusa3

Interesting! Are you publishing your design files someplace?

@Shane_Graber My fork is at https://github.com/AxTheB/Prusa3 and I regularly push the changes to main Prusa3 repo https://github.com/josefprusa/Prusa3 in the box_model folder.

With regards to tensioning of the X-axis belt would’t it be simpler to modify the X-carriage or by making the motor mounting holes slotted?

Must admit mine sat just right by beefing up the bearing guide fractionally, though it would definitely make sense to have some way of adjustment on the belts.

@Vaclav_Hula : FYI I think you inadvertently pushed an update to the single_plate folder that breaks the extruder mounts. Your latest update to the single_plate folder makes the x-carriage wider and places the mounting holes 30mm on center however none of the extruders in the single_plate folder have been updated for these wider holes. Thus the compact_extruder and dual_compact_extruder won’t attach any longer as their mounting holes are 24mm on center.

@Simon_Day I think that messing with stepper or carriage will not come near the ultimate user-friendliness of tensioning with single screw that serves no other purpose and is easily reached.

@Shane_Graber Check commit author, that was Joaz not me. The single_plate folder is without maintainer, as Josef is not publishing his changes there and we (me, Joaz and Kliment) are working on the box_frame only. It produces working models for single plate too.

And the update was because before Joaz switched to using box_frame models he was using single frame with MGS extruders. Long time ago Josef said hes ok with switching to agreed standard of 30-20-30 hole spacing, but he is hard to cooperate with:)

@Vaclav_Hula : Should I revert the change so it’s consistent? I have commit access as I’m the maintainer of the wood frame in the single_plate folder: https://github.com/josefprusa/Prusa3/tree/master/single_plate/src/frame/6mm I’m seeing people print the parts from the single_plate folder and I don’t want them frustrated that the extruder doesn’t work on it.

If you want to make changes, fix extruders not break carriage.

Color me confused, but the commit broke extruders and I believe the NEMA17 extruder Josef is using still uses the narrower x-carriage. Right now this commit broke everyone’s extruder design. Honestly if a commit is made that affects another part, shouldn’t that commit to a public git not be made until someone rectifies the problem with affected parts? I’m not trying to be argumentative. I just don’t understand.