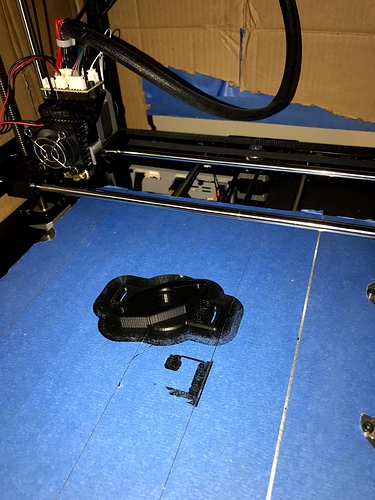

Switched from PLA to ABS and came out with this! 3rd print I’ve ever made in ABS (and the first two were calibration prints). This is a TPS bracket for a Mazda 1.6 L Miata to use a Kia TPS. Turned out really nice! Maybe it’s my RB2 printer, but printing in ABS doesn’t seem to be as intimidating as I thought it would be. I didn’t have to do any tricks with bed adhesion. Just a good brim.

My ABS prints would always start nicely but they’d peel themselves off my printer bed before finishing with curled corners. This looks great!

Cool. Trump made it hard to google for TPS.

@Fen11 yeah! My first calibration print curled a lot, but it didn’t have a brim. When I put the brim on, and smashed it into the bed pretty well, it worked great!

Are you using Mega Squirt?

I find printing in ABS to be the easiest, PLA gives me all sorts of greif.

@Rob_Wilson It’s been an interesting experience for me. I’m really happy with the quality to this point. I’ll have to retry some prints that I did in PLA and compare the differences.

If you like ABS, try PETG. I found that using the same settings as ABS worked very well.

@Noel_Kuck Great minds and all that. I’m buying 2 rolls of PETG tomorrow to print the parts for my Hypercube-300 build.

@Rob_Wilson @Noel_Kuck Good suggestion. I like to have a range of experience with different filaments. Sounds like that might be the next one to try. The prices of PLA, ABS, and PETG all seem really similar on Amazon.

You might have to adjust retraction details due to the sometimes stringy nature of PETG.

Really nice job here! Was the printer enclosed or did you leave it open air?

It gets harder as the prints get taller. Printing a tall-walled box of significant size will curl off the bed unless you have an enclosure for example. A simple enclosure helps a lot. I have a simple box made out of fake garden-centre bamboo, 3d-printed corner pieces, bubble wrap and duck tape – works well.

@Daniel_Jackman It does not take much of an enclosure to be really effective. Now to try some taller prints,

@Jeff_Parish Something else to try (I did and was amazed): I sat in on a discussion from a guy who does a lot of commercial printing. He said that what he does is use 60 grit sandpaper on his glass bed! Period! It provides enough of additional surface tension that he doesn’t even use hairspray or glue, although I tend to use a little glue just to play it safe.