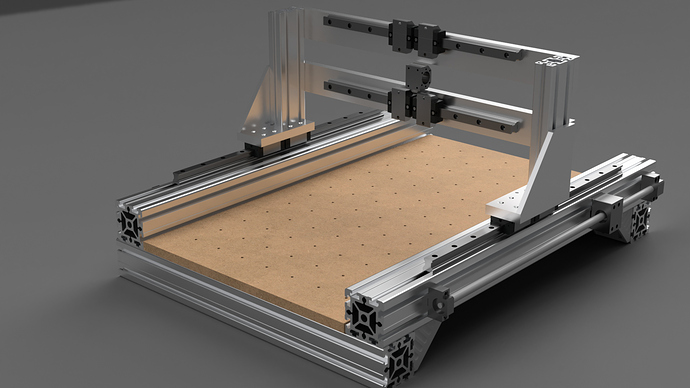

Some updates on my DIY CNC design.

Give me a hint if I spam this group with all my images/updates…

Shiny = happy

With progress like this, you SHOULD keep posting.

I have a question: sort of a mechanical engineering/structural question. Would placing the Y slides at a higher Z location (like centered between the two x slides), make a stiffer assembly? Or is it better to have this assembly (with risers on either side), where the force applies itself closer (Z) to the material/bit?

Sounds correct, but I do not know. If the rest of the frame is stable.

of course you should post here. you give me a lot of insperation

Would something like this work/be stable? All in 20mm alu.

Have not included any screw holes yet.

missing/deleted image from Google+

Im going to get some longer 90x90 Bosh Rexroth alu profiles + Rexroth 25mm rails (1200mm), so then Im going to move the 700mm rails to the X-axis. Using the new profiles, I`m going to get a 1000x500mm work area.

Updated design soon.

More like this

missing/deleted image from Google+