So I’m relatively old-hand at this three-dimensional printing mumbo jumbo, but this issue has me totally stumped. Seems like it’s been happening ever since I replaced a burned out RAMPS 1.4 board, though that may be coincidence. I’ve recalibrated all my estep values, swapped around a couple pololus, tweaked voltages with the pots, tried a wide range of temperatures and layer heights. Tried different filament, different slicers, even a different hot end.

It seems like at random intervals I just get a poorly extruded layer. Could my extruder stepper be dying? I have no idea what the symptoms of that would be. Any ideas?

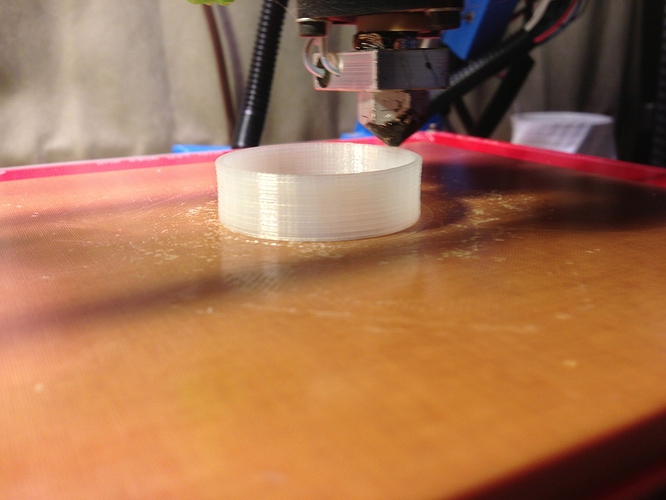

Hard to make anything out in those pictures. I’d need some macro shots. What you’re talking about sounds like filament slipping on the drive gear, but I have a different hypothesis. How are you feeding filament into the machine? If there’s resistance on your spool, it could be pulling the extruder up a bit when it goes taught and printing a bit too high above the previous layer.

More info in my article in the reprap magazine: http://reprapmagazine.com/

I have read your article, Rich, it’s excellent. Unfortunately relieving tension from the spool doesn’t seem to make any difference. I have consistent measurements of extrusion length, so I don’t think it’s filament slippage either.

I guess I need to buy a macro lens.

Another possibility is just bad plastic. I’ve seen plastic with frequent changes in diameter, variable density, and even some with long bubbles of air down the center.

I have the same experience. It’s probably bad plastic. What I’ve done was try and compensate by increasing the extrusion multiplier in your slicer.

Mostly been printing with 1.75mm Taulman nylon lately, though this was happening with 3mm also. There’s some variation in diameter, but doesn’t seem to be more that +/- .05mm. I wonder if it’s a density thing…

If it’s nylon, it’s probably slipping. That stuff is really slippery. It’s also more compressible than other filaments, so it’s tougher to get even extrusion when it’s retracting a lot or the temperature is swinging. How smooth is your temperature while printing? You may need to adjust your PID.

I had this problem before with a Z axis motor that didn’t have enough power. There were certain settings that it couldn’t reach so 0.1, 0.2 get double printed, then 0.3 it jumps up 0.2mm and doesn’t adhere to the next layer well. Fixed it by increasing the power on the z axis stepper drivers. Just a guess, could be the plastic like others are suggesting. I happened to have tweaked my power settings to eliminate a really awful whining noise previously. Mind didn’t suddenly start working poorly.

Thanks, guys. I seem to have a pretty good grip on the nylon. I can actually grab the line and pull against the extruder pretty hard before it starts to slip. Temps are stable +/- 1 degree for the most part.

I think it is a power issue. Played with the z-axis potentiometer (turned it down) and eliminated it completely. For one print. Now it’s back. I wish I knew why it was happening.

Since you have a RAMPS board you can power everything off and try switching or replacing the stepper motor drivers. The A4988/A4983 stepper motor driver for that axis might be going bad. http://www.pololu.com/catalog/product/1182 is what I’m using with RAMPS 1.4. I let the magic smoke out of two of mine so far doing stupid stuff / learning how electronics work.